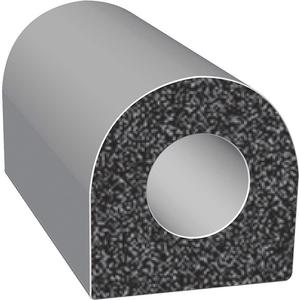

Trim Lok X1458BT-25 D-shaped rubber seal is ideal for eliminating sound or vibration in sound enclosures & heavy machinery and protecting them from contaminants or extreme weather. This rubber trim seal is foam adhesive acrylic backed for easy installation on windows or doors.

Features:

- Trim Lok D-section rubber seal has self-adhesive properties and is available in two tape options that are BT (a 3M bonded tape system) and HT (a conventional pressure-sensitive adhesive).

- It is a specifically manufactured EPDM sponge rubber compound that comes in 0.75 inch width.

- This unit resists ozone & sunlight ageing and provides excellent water absorption and compression.

- It operates at temperatures ranging from -20 to 150 degrees Fahrenheit.

Standards and Approvals:

Frequently Asked Questions:

Q. How to use this rubber D seal?

A.

- Clean the work surface thoroughly with disposable wipes or lint-free wiping clothes.

- Do not stretch the rubber seal from the reel.

- Avoid getting adhesive dirty.

- Install the rubber seal around the radius by stuffing and not stretching.

- Use a hand / automatic roller and apply the pressure against the seal for good wet out of the adhesive to the surface and long term durability.

- Always store on original reels and store in cool, dry & dust-free location.

Q. What is HT pressure-sensitive adhesive?

A. The rubber seal is installed with this acrylic-based glue best when it is squeezed between two stationary objects or utilised in a static application. It may be used for several substrates in some light-duty dynamic applications and offers good heat conductivity between -20 and +150 degrees Fahrenheit. The surrounding temperature must be above +60 degrees Fahrenheit during application.

Q. What is BT 3M high strength adhesive?

A. This 3M Acrylic Automotive grade tape ensures an airtight seal and moisture barrier between the rubber and the substrate. To employ the highest peel and shear resistance, high amounts of stress and force can be applied. Low initial tack makes it simple to reposition during installation, but it takes 72 hours to cure before it reaches its maximum binding strength. It offers good heat conductivity between -20 and +150 degrees Fahrenheit.