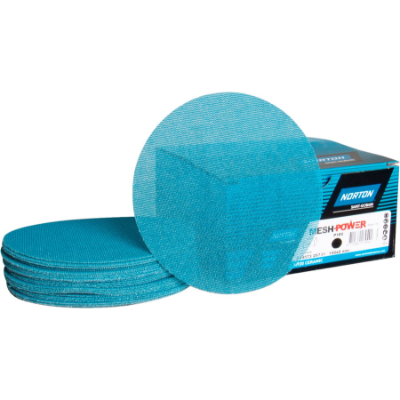

No-fil Coating

No-fil coating on Norton Abrasive discs and sheets prevents clogging due to dust buildup. It extends disc life by resisting loading when sanding wet or dry.

These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

With its headquarters in Stafford, the United Kingdom, Norton (a brand of Saint Gobain) manufactures quality abrasive and non-abrasive solutions for grinding, cutting, polishing, finishing and bending operations in repair & maintenance and manufacturing applications. Read More

Used for creating a desired surface finish where very little stock removal is required. Feature a non-woven synthetic fibre mesh construction impregnated with aluminium oxide / silicon carbide abrasives and bound by resins

Cylinder toolroom wheels and plate-mounted grinding discs designed for vertical-spindle surface grinders and double-disc grinders to machine hard or heat-sensitive high-speed tool steels

Includes a variety of Type 27 Norton Wheels designed to handle right-angle grinding applications on steel, aluminium and cast-iron surfaces. Available in different abrasive materials and grit sizes

Ideal for grinding reinforcement bars or protruding bolts. Feature free-cutting diamond abrasives with fine grits to ensure a precise operation, and a resin bond for maximum grain retention

Ideal for smoothing weld beams, cleaning castings or preparing surfaces for plating in foundries, welding stations, fabrication facilities and steel mills. Capable of delivering wheel rotational speed of up to 9070 rpm

Grind, contour and polish intricate shapes in metal fabrication and welding applications. The continuous series of individual flaps provide a uniform finish. Use a retainer nut to securely lock the wheel onto the machine. Available in a rotating speed range of 8000 - 30000 rpm

Achieve precise finishes and tight geometry tolerances when used in conjunction with grinding machines. Equipped with recesses to accommodate mounting flanges with an overall diameter ranging between 12 & 14 inches. Come in Type-5 one-sided & Type-7 two-sided variants

Non-reinforced / reinforced wheels with fibreglass discs or / and steel rings suitable for precision and rough grinding applications. Feature abrasive grains offering a high ratio of material removal to wheel use. Available in fine, medium, coarse and extra-coarse grained variants

Facilitate precise edge deburring and finishing jobs on small or intricate workpieces. Feature aluminium oxide / silicon carbide construction for an optimal cut rate and a controlled density range for additional durability

Used for thread cleaning and deburring applications. Feature a threaded arbor hole to attach the wheel to the tool and grinding cones & plugs with a durable resin bond for efficient grinding of titanium, super alloy, 300 & 400 Series stainless steel and carbon steel

Pressure-sensitive adhesive discs designed without a centre-hole to offer full-face usage. Feature cloth / paper backing pads for reduced edge wear and can be used on portable / stationary grinders and sanders

Can be mount on angle grinders or sanding machines using an arbor or a mandrel for applications ranging from heavy stock removal to surface blending jobs. Available in aluminium oxide, ceramic, silicon carbide and zirconia alumina abrasive materials

Includes a wide range of Type 27 and Type 29 flap discs designed for right-angle grinder applications. Available in different abrasive and backing materials

Suitable for dry sanding and fine finishing services on wood, plastic, fibreglass, composite, primer and sealers. Integrated with Cyclonic technology that extracts 60 per cent more dust. Available in diameters ranging from 5 to 7 inches

Includes a variety TR, TS and Type 3 Norton sanding discs designed to perform dry sanding operations. Available in different colours, disc diameters and abrasive materials

Includes a variety of coated and non-woven sanding belts with aluminium oxide, ceramic aluminium oxide and zirconia alumina as abrasive material options

Compatible with paint, primer, softwood, metal, plastic, hard & soft composite and fibreglass surfaces. Contain no pigments or dyes, thereby eliminating any chances of colour transfer to workpieces. Selected models come with 5 to 6 vacuum holes

Aluminium oxide, Arkansas stone and silicon-carbide abrasive files used for sharpening cutlery, curved knives, gouges and deep-grooved tools. Selected models featuring pointed edges also available

Includes benchstones, specialty sharpening stones, utility stones and waterstones used for sharpening laboratory blades, surgical instruments & die tools. Available in grit sizes ranging from 150 to 8000

Stackable diamond benchstones comprising a flat-diamond surface plated on a nickel-coated steel bar to deliver a fast and even tool edge sharpening. Available in 220 and 325 grit sizes

Used to true or dress grinding wheels made from stainless steel, hard / soft carbon steel and tool steel. Available in grit sizes ranging from 20 to 400

Used for rubbing floors, cleaning and scouring castings, rubbing down concrete and removing mold marks. Selected models feature a diagonal flute design, resulting in sharp edges, to offer a clean sharing action. Available in coarse & extra coarse variants for heavy-duty applications

Used to sharp, debur, chamfer and fit delicate metal parts. Feature bonded abrasives composed of aluminium oxide & carbon carbide / synthetic material to cater to all sharpening needs and provide faster cutting

Designed for sharpening scissors, scythes, knives, razors, chisels and plane blades. Come in fine, ultra-fine, medium, coarse and extra-coarse grained variants for faster stock removal rates and edge shaping with minimal loading

Designed to remove parting lines, imperfections and burrs from hard-to-reach internal diameters, edges or contoured components. Feature a spiral construction to offer a chatter-free cutting action with a maximum speed of 15000 rpm

Foam / plastic / rubber backup pads designed for use with quick-change and fibre sanding discs. Can be mounted on mandrels or spindles of orbital sanders and mini grinders. Capable of providing up to 30000 rpm speed

Provide a concrete foundation for accommodating the sandpaper and a curved contour shape to comfortably fit the hand. Also, integrated with coated abrasives and surface conditioning discs or sheets

Used with sandpaper to provide a stable foundation to smoothen surfaces and remove loose paint / grit / dirt during painting or refinishing applications. Feature a curved contour for a comfortable grip and an in-built air chamber to keep the workplace clean & dust free

Includes cloth-handy, non-woven and paper-handy rolls ideal for light-duty deburring, blending, sanding and finishing operations. Available in aluminium oxide and silicon carbide abrasive materials with grit sizes up to 1200

Aid the user to get into curved, contoured or hard to reach places when smoothing out finish on metal / wood / stainless steel. Coated with aluminium oxide to effectively deburr and polish. Available in grit ratings up to 150

Integrated with a special-foamed backing for maximum grip while sanding round edges, contours and curves, as well as finishing top coats and primers. Come color coded, by grit size, for easy identification

Designed to clean up jagged edges and remove dust or rust; suited for use with concrete, stone, ceramic or glass surfaces. Feature a color-coded configuration for easily identifying the grit sizes

Made of abrasive-coated foam for stripping, sanding & finishing applications, as well as minor defect removal & surface key creation. Flexible design allows use on curved, contoured and flat surfaces. Available in coarse, extra coarse, medium, fine, super fine, micro fine & ultra fine variants

Includes a variety of sizes & shapes of bonded abrasive points for use on die or in-line straight shaft grinders. Packed in a corrugated box to retain all the points in one container for easy retrieval at jobsites

Assure rapid stock removal & prolonged life; ideal for both small shop and high volume foundry operations. Available in aluminium oxide, ceramic, cubic boron nitride, diamond, silicon carbide and zirconia alumina abrasive materials

Norton Abrasives catalogue comprises surface grinding wheels, sandpaper sheets & strips, flap wheels & mops, hand pads, sanding discs, rolls & belts, different types of grinding, cut-off & surface conditioning wheels and more.

Norton sanding belts are commonly used to shape and finish wooden and metallic surfaces during grinding and deburring operations.They are offered as coated and non-woven sanding belts with a variety of abrasive materials (including aluminium oxide, zirconia alumina and ceramic) to choose from. The durable and versatile Norton flap discs are a popular grinding and finishing tool designed for heavy stock removal and surface blending.

Norton Abrasives product's MPNs (manufacturer's part numbers) generally cross individual reference to the equivalent ARC Abrasives, Merit & 3M model numbers. So, if you're looking for a similar product that is either out of stock or obsolete, chances are Raptor Supplies has an alternate product available.

These Norton Abrasives products are generally small in size and require compact packaging. They are suitable for courier shipment and not air freight.

Norton MeshPower discs are designed with multiple holes & a unique mesh matrix structure for dust extraction in general applications. They can be used wet or dry due to their exclusive No-fil technolo...Read more

Norton Blaze Rapid Strips are mounted on angle grinders for removing surface rust, residue,weld spatter, dirt, mill scale and other surface contaminants to prepare the workpiece for coating, painting ...Read more

Beartex high strength discs are installed on a bench or die grinders using a mandrel for rust or coating removal, polishing, contaminant removal and more. They feature high-strength, smear-proof resin...Read more

No-fil coating on Norton Abrasive discs and sheets prevents clogging due to dust buildup. It extends disc life by resisting loading when sanding wet or dry.

Vitrified mounted points are used along with grinding machines for grinding small, intricate, curved metal pieces in foundry, tool room & aerospace industry. These vitrified mounted points use ceramic Quantum grain and Vitrium3 bond technology for higher removal rate of material, ensuring long operating life compared to other abrasive mounted points. Vitrium3 bond technology offers cool cutting & profile holding at high speeds, whereas the Quantum ceramic grain developed from Norton's patented Seeded-Gel technology increases the cutting efficiency by providing a micrometric level breakdown.

Norton Abrasives products are manufactured across the globe in Staverton, Gloucestershire and Raleigh Hall, Eccleshall and Stafford in the United Kingdom.

The grit / grade of sandpaper denotes the size of abrasive materials present. A high grit size (600 etc.) indicates finer abrasives in the sandpaper, resulting in smoother surface finishes, whereas the lower grit sizes (30, 60 etc.) represent coarser abrasives used in heavy sanding and stripping applications. Users should choose appropriate sandpaper according to their applications for fine or coarse grinding while considering the material (workpiece) properties.

The abrasives used in grinding wheels are aluminium oxide, silicon carbide, ceramic grain, zirconium aluminium oxide, cubic boron nitride and diamond.