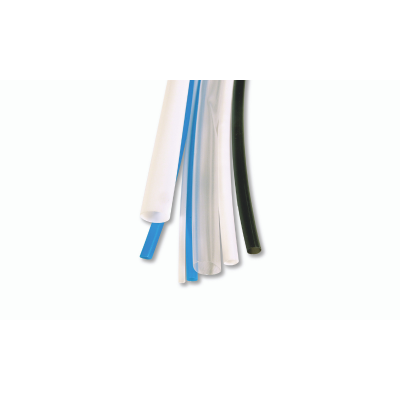

Xtra-Sheild

Xtra-Shield is a product line of radiation cross-linked acrylated olefin tubing with a 2:1 shrink ratio and is available in colour variants of black, white, blue and clear as per the requirement. This tubing features a proprietary additive-free formulation, ensuring non-toxicity. It offers superior insulation integrity and reliability, tightly fusing to substrates and preventing slippage. This tubing has dielectric strength, durability and enhanced resistance to chemicals.