These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

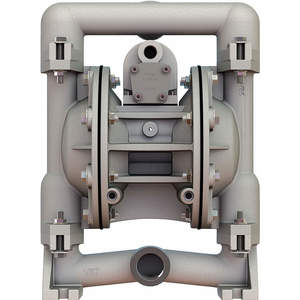

VERSA-MATIC E1SA5T559C-ATEX Diaphragm Pump 49 Gpm 125 Psi

Get it by Tuesday, Apr 8

Payment

Delivery

Product Specifications:

| Item | Double Diaphragm Pump |

| Air Inlet Size | 3/8" |

| Ball Material | PTFE |

| Body Material | Stainless Steel |

| Check Seat Material | Stainless Steel |

| Connection Style | NPT |

| Diaphragm Material | PTFE |

| Height | 14 35/64" |

| Inlet/outlet Size | 1" |

| Length | 9 21/64" |

| Manifold Connection | Single Port |

| Max. Dia. Solids | 1/8" |

| Max. Flow Gpm | 49 |

| Max. Operating Pressure | 125 psi |

| Max. Temp. | 220 Degrees F |

| Operation Type | Air Operated |

| Self-priming Dry | 16 ft. |

| Self-priming Wet | 31 ft. |

| Valve Material | Ptfe |

| Valve Type | Ball |

| Width | 10 23/32" |

Shipping Info:

| Ship weight (kg) | 17.89 |

| Ship height (cm) | 27.94 |

| Ship length (cm) | 35.56 |

| Ship width (cm) | 40.64 |

| HS code | 8413500050 |

Product Details:

Versa-Matic E1SA5T559C-ATEX diaphragm pump is suitable for transferring liquids, such as chemicals, oils and solvents. Its design, featuring diaphragms that move back and forth, enables efficient pumping without exposing the fluid to mechanical parts. This makes it suitable for applications where contamination must be minimised, such as in chemical processing plants, oil refineries and hazardous environments.

Features:

- It has 316 stainless steel housing material, ensuring long-lasting performance in various environments.

- This double diaphragm pump has a self-priming feature, simplifying the setup process and ensuring efficient operation.

- It includes a reliable ball valve type, providing smooth fluid control with minimal maintenance requirements.

- This double diaphragm pump further features multiple flow rate options, ranging from 26.5 to 48.2 gpm, catering to different application needs with precision.

- This double diaphragm pump features a pump assembly type of bolt, ensuring secure and stable construction for reliable performance in demanding applications.

- It has a diaphragm and valve material of PTFE, ensuring excellent chemical resistance and reliable performance in handling a wide range of fluids and chemicals.

Frequently Asked Questions:

Q. What power source does this diaphragm pump require?

A. This pump can be powered by compressed air, with an air consumption rate of 50 standard cubic feet per minute (SCFM) and a rated air pressure of 125 PSI.

Q. What type of connections does this pump feature for fluid intake and discharge?

A. This pump is equipped with 1-inch NPT connections for both fluid intake and discharge, providing standard connections for easy integration into existing systems.

Q. What safety precautions should I take when using this diaphragm pump?

A.

- Read the manual thoroughly before operating the pump to understand safety guidelines.

- Install the pump correctly according to manufacturer's recommendations to prevent accidents.

- Ensure all fluid connections are tightly secured to prevent leaks during operation.

- Wear appropriate PPE, such as safety glasses and gloves to protect against chemical exposure.

- Operate the pump in a well-ventilated area to avoid accumulation of hazardous fumes.

- Ensure proper grounding of the pump and associated equipment to minimise static electricity buildup.

- Monitor discharge pressure regularly to prevent equipment damage due to overpressurisation.

- Know emergency shutdown procedures and locate emergency stop buttons or valves.

- Provide adequate training to operators for safe pump operation and maintenance.

Explore Products

- CONDOR 4NHF2 Leather Palm Gloves Hi-visibility Lime L Pr

- TSUBAKI RS12-1B13F-1C

- GRAINGER BULK-RS-NHS50-43 Neoprene Sheet, 36 Inch X 36 Inch, 0.03125 Inch Thickness, 50A

- HARRINGTON TCS1000P2-15 Air Chain Hoist 2000 Lb. Capacity 15 Feet Lift

- GRAINGER BULK-RS-S10-45 Silicone Strip, 1/2 Inch X 36 Inch, 10A, Silicone Adhesive Backed, Red, Smooth

- EATON A27SRC25TP16 Definite Purpose Starter, 25A, 24 V, 50/60 Hz, 0.1-0.16 Fla, 3-Phase, Non-Reversing

- MARTIN SPROCKET S816BS 1 Spur Gear, 8 DP, 14.5 Deg., 16 Teeth, 2 Inch Pitch Dia., Bore To Size, Steel

- APPROVED VENDOR M51000.040.0040 Hex Head Cap Screw, M4x0.7 Thread Size, SS, 40 mm Lg., Gr. A2, Plain, 50 Pk

Explore More

- CALPIPE SECURITY BOLLARDS

- HUBBELLOCK

- KEYSHAFT

- MORSE DRUM

- GUARD LINE

- Milling and Drilling Machines

- Regenerative Blowers

- Hazardous Location Lighting Accessories

- Welding Ovens

- Microscope Accessories

- DESTACO 2017 Series Horizontal Hold Down Clamps

- ANSELL 83-500 Touchntuff Sterile Polyisoprene Gloves

- RINGERS GLOVES R-266 Insulated Impact Gloves

- CONDOR High-Visibility Vest, ANSI Class 3, Mesh Polyester, Hook And Loop, Lime

- MILLER - WELDCRAFT Collet Copper Gas Lens

- VULCAN HART Stub Riser

- VERMONT GAGE NoGo Standard Thread Plug Gages, 2 7/8-8 Thread

- SPEARS VALVES PVC Compression Male Adapters, Elastomer Gasket

- PARKER Replacement Filter Elements

Contact us

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.