- Categories

- Brands

Includes 12-lead capacitor-start and single- / three-phase motors specifically designed for 50 Hz applications in conveyors, blowers, pumps & air compressors. Feature B / F Class insulation to withstand temperatures up to 155 degree C

Single- / three-phase motors best suited for applications involving farm & agriculture equipment (such as conveyors, feeders, fans & silo unloaders) which might get exposed to dust, dirt or water. Feature double sealed ball bearings, a gasket capacitor case & a conduit box cover

UL recognised and CSA certified motors designed for machines requiring constant and variable torque. Feature capacitor start / run design for higher efficiency and Class F & H inverter-rated insulation system for temperature ranges up to 180 degrees C. Equipped with normally closed thermostats

Designed for hazardous atmospheres containing combustible dust / explosive gases. Feature double-shielded & pre-lubricated ball bearings to withstand an internal explosion of gases / vapours and are totally enclosed motors (fan-cooled or non-ventilated)

Designed for woodworking equipment like table saws, planers & lathes. Feature a completely enclosed design to prevent wood shavings and dust from entering the motor, come with TEFC enclosures and are offered in voltages ranging from 115 to 230 V. Class B and F insulation variants also available

Single- / three-phase motors designed for air compressor, fan, pump and blower duty applications requiring rugged mechanical construction & high breakdown torque. Feature double shielded ball bearings, highly efficient copper windings and dual rotation for safer & smoother operation

Specifically geared for applications exposed to occasional washdowns. Feature capacitor start / run design to reduce amp draw, as well as dynamically balanced rotors & manual reset overload protection. Drains for mounting enable effective & flexible installation

HVAC / TEFC condenser fan motors featuring enclosed endshields on the shaft ends to protect the sensitive components from dust, moisture or dirt and a high-starting torque facility for efficiently handling belt-driven fans

CSA certified & UL recognized motors designed for industrial & commercial pumping applications; feature 416 stainless steel threaded shafts & terminal board with quick-connects. Available with drip cover kits and in single- & three-phase motor designs

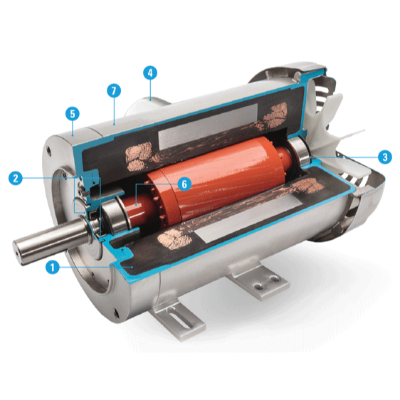

Designed as per EPACT & premium energy-efficient standards for use in blowers, pumps, conveyors & other industrial machineries. Generate energy with the help of a rotating magnetic field. Available in different hazardous location classes, enclosures, mountings & horsepower ratings

50 / 60 hz brake motors featuring Stearns high-cycle brakes to stop the motor instantly; ideal for applications requiring quick response holding & breaking operations. Come equipped with TENV / TEFC / DP enclosure to prevent the ingress of contaminants

Work on AC power and are used as replacement motors for machine tools with metric dimensions. Feature Leeson's patented Inverter-Rated Insulation System for protection from voltage spikes and a steel fan cover & low-noise fan for increased airflow efficiency. Operating voltage ranges between 12 and 575 V

Ideally used for applications requiring adjustable speed, dynamic braking & constant torque facilities all along the operating range. Feature a steel bolt-on base for absorbing impact loads & vibrations and offered in 1.00 and 1.38 form factor options

Use permanent magnets for startup power. Known for high efficiency & power density and low maintenance requirements. Have C face less base & TEFC enclosures.

High starting torque motors suitable for use in applications where the load is not altered by the speed. Designed for mechanical loads or hard-to-start applications in hoists, conveyor belts, positive displacement pumps & mixers. TENV & TEFC variants are available.

Leeson is a leading provider of UL and CSA recognised AC and DC motors, gearmotors and motor accessories. These motors are ideal for rugged use in commercial and industrial settings and are widely used in pumps, compressors, blowers & fans. The brand's 1 and 3-phase AC motors are explosion-proof and designed for continuous duty applications in the agriculture, woodworking and metallurgy industries. Leeson DC motors are SCR-rated general-purpose motors with a low form factor suitable for food processing applications.

These motors are ideal for farm agricultural machinery. They provide high torque performance and increase efficiency up to 22%. They have sealed ball bearings for added protection and longevity. These...Read more

With constant exposure to high-pressure sprays and harsh chemicals, even the smallest crack could cause motor damage or bacteria build-up. Extreme Duck Ultra motors have encapsulated housing and end b...Read more

They provide desired output power while fitting into small frame sizes. These motors have powerful magnets that allow them to run at high speeds. Their compact design enables the reduction or eliminat...Read more

Gearmotors are available in both alternating current (AC) and direct current (DC) models, in right angle and parallel shaft designs. Conveyors, packaging machines, mixers, farm equipment, cranes and hoists use AC gearmotors, whereas spreaders and low voltage or battery-powered equipment use DC gearmotors.

Leeson Motors offers a wide range of energy-efficient motors to meet industry efficiency standards like the NEMA Premium Efficiency standards. However, users should keep in mind that energy efficiency also depends on the application and how the motors are used. The use of a properly sized motor and selecting the right operating speed & voltage can also improve efficiency.

Yes, Leeson motors can be customised for specific applications. They can be tailored to meet specific customer requirements, including the installation of custom shafts, leads, mountings and enclosures.