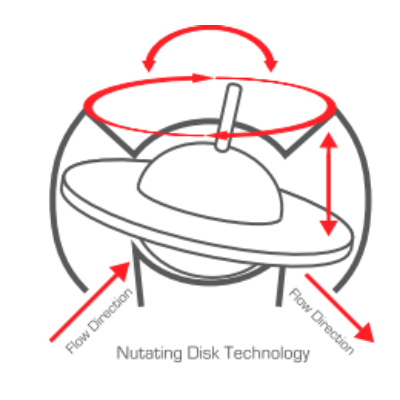

Nutating Disc Mechanical Metres

Nutating disc mechanical metres have accuracy of +/-2% and are designed to measure & totalise fuels (gas / diesel) transferred on-site. Normally, they are paired with a Fill-Rite pump for rapid fuel transfer, but they can also be used for gravity feed systems, and produce flow rates ranging from 5 to 40 GPM. TN Series pumps are the perfect choice if you're looking for pumps that can handle higher flow rates (up to 60 GPM) and pressure levels (150 - 1500 PSI). TN Series pumps are ideal for diesel, as well as automotive and industrial fluid applications.