These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

CHRISLYNN

Chrislynn, headquartered in Auburn, United States, is a leading manufacturer of high-quality threaded inserts designed to create new threads or repair damaged internal threads. The threaded inserts are widely used in the mining, oil drilling & refining, automotive, avionics and power generation industries. Read More

Filter

Fasteners

Machining

Pumps

Pneumatics

Fasteners Filter

Thread InsertView all

Thread Inserts Repair damaged threads or create threads in unthreaded materials. E Z Fix inserts provide great holding power in materials for a strong & durable threaded connection.

Hex Drive Thread Inserts A type of threaded insert with a hexagonal drive on the top that allows them to be installed and tightened using a hex wrench or socket. Used in applications where a high level of torque is required and where the threaded insert is subject to high levels of vibration or stress.

Left Hand Inserts Designed with a left-handed thread for turning counterclockwise and repair damaged threads or create threads in materials that are not threaded. Necessary in applications where a left-handed thread is required.

Helical Thread Repair Inserts Repair damaged threads to provide a strong, durable threaded connection and restore the functionality of a damaged threaded hole. Available in diverse thread types, including UNC, UNF, Metric Coarse, Metric Fine and others to suit different applications.

Helical Thread Insert Tools High-quality steel / carbon steel installation, combination, breaker and extraction tools designed for easy installation of new or removal of old helical style inserts from threaded holes

Blank Helical Inserts Include rock solid blank inserts, a type of rock solid insert that do not have prepared internal threads. Used in applications where a nonstandard size combination is required. Available in 303 stainless steel or carbon steel construction.

Free Running Helical Inserts Free running inserts offering easy threading into a damaged or stripped thread without tapping or threading the hole first. Provide a durable and strong repair thread over stripped threads.

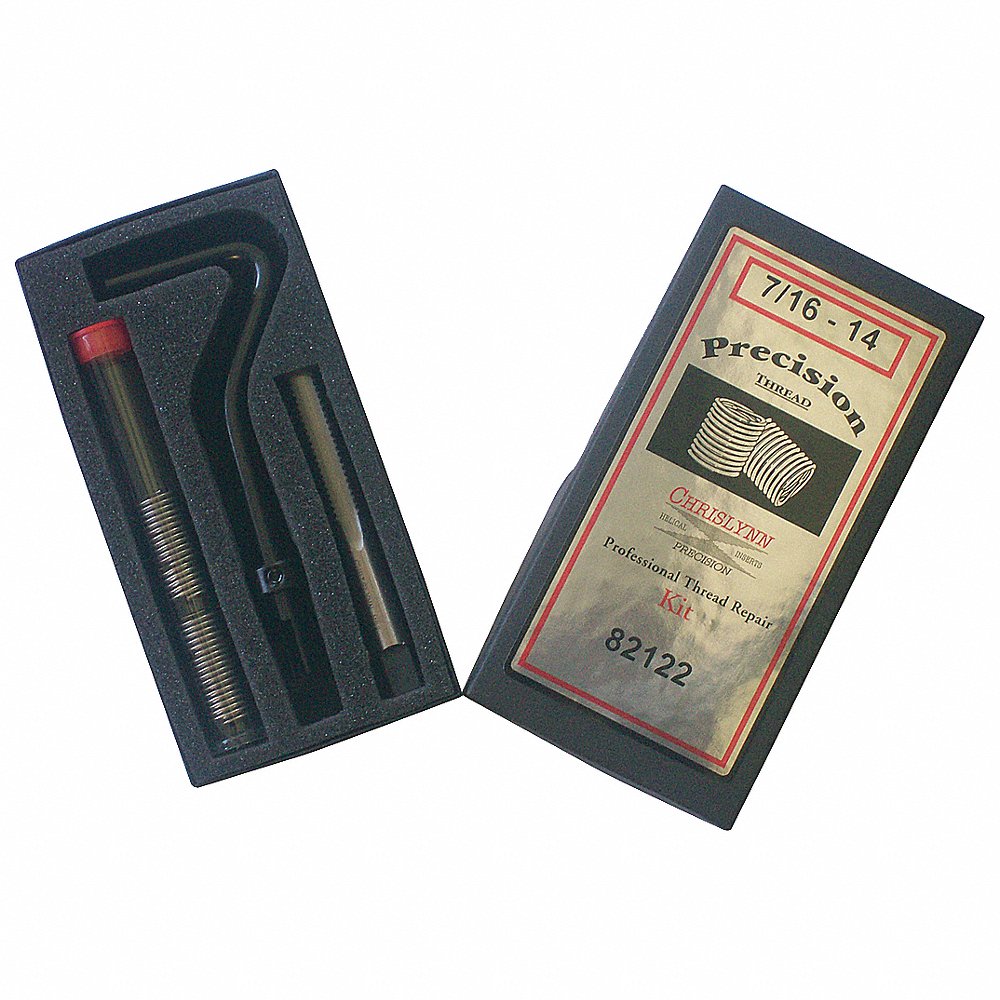

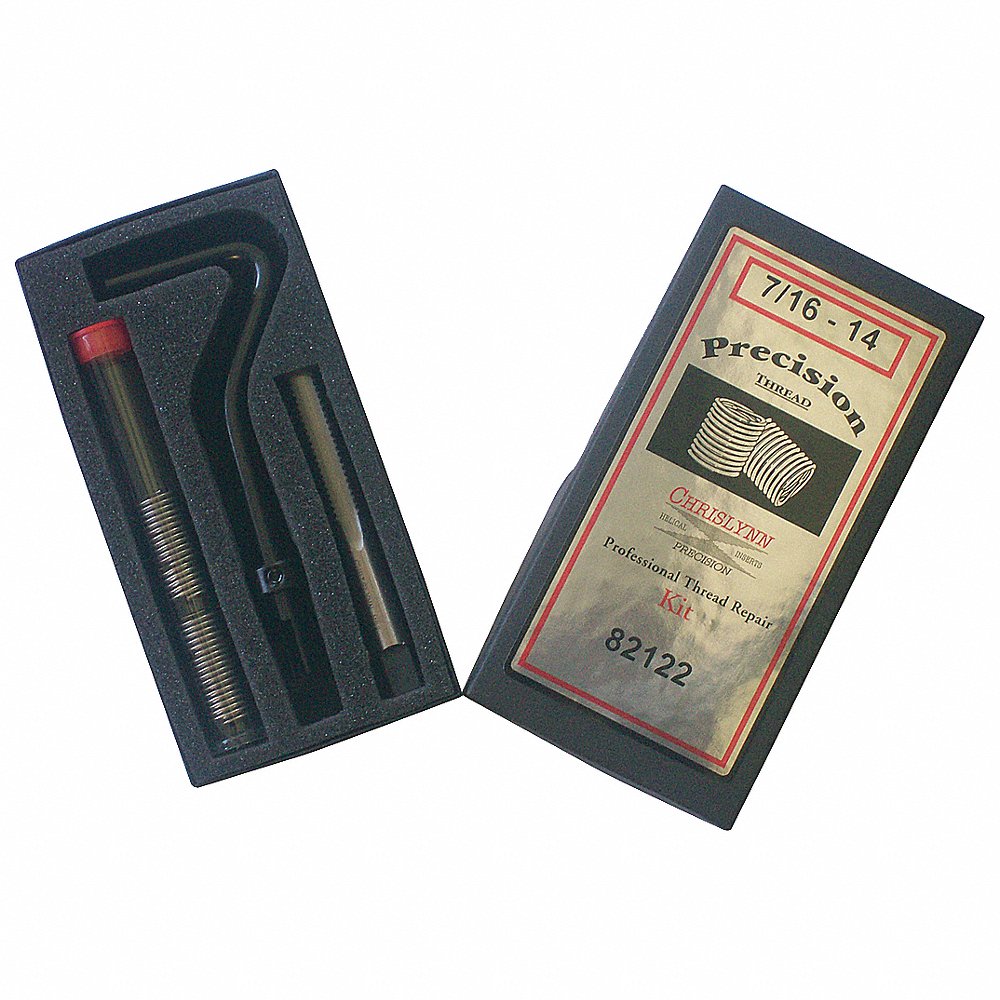

Helical Thread Insert Kits Used to repair stripped threads in metal, wood, or plastic by installing a helical thread insert. Provide a new surface for the screw or bolt to grip. Generally include a tap for cutting a new thread in the material, an installation tool and a supply of helical inserts in various sizes.

Locking Helical Inserts Create strong and durable threads in unthreaded materials or repair damaged threads. Provide a secure, locking connection that resist loosening over time. The locking mechanism is achieved through various means like tangs or barbs that grip the walls of the hole & prevent the rotation of insert.

ScrewsView all

Fastener Assortments Include rock solid insert assortments that are pre-packaged sets of rock solid inserts for easy replacement in an application. Available in carbon steel and stainless steel constructions.

About Chrislynn

The Chrislynn inserts catalogue includes precision helical, rock-solid (K-Type) and E-Z Fix inserts. The brand's BSF repair kits quickly restore or repair stripped, worn and damaged threads in sheet metal, fibreglass or other brittle materials. These kits include stainless steel inserts, tools and STI plug taps. Drill bits by Chrislynn are designed to facilitate the easy installation of thread inserts. These bits are capable of cleaning damaged or worn-out inserts, thereby paving the way for new inserts. Choose from a wide range of drill bits & cutting tools from Chrislynn on Raptor Supplies.

Things to Consider

Cross-Reference Alternatives

Chrislynn's MPNs cross individual references to the equivalent Grainger, Helicoil and E-Z LOK model numbers. So, if you are looking for competitor items that are either out of stock or obsolete, chances are Raptor Supplies has the equivalent Chrislynn inserts available. Customers can also cross-reference most products using the last 5 digits of the model numbers.

Shipping

Chrislynn inserts are small in size and supplied in multiple pieces, therefore require careful packaging as some products might get damaged while shipping. Hence, they are delivered by courier shipment and not air freight for minimum downtime.

Major Trade Names

E-Z Fix Inserts

They are threaded inserts with a solid design that are either composed of carbon or stainless steel. These inserts are available in metric and American measurements having thin walls and heavy-duty or...Read more

Rock Solid Inserts

They have wedges (keys) affixed to the top and are top-threaded on the exterior. The inserts are screwed into the component once the part has been rethreaded and the wedges are pushed into the tapped ...Read more

Frequently Asked Questions

Why are rock solid inserts unique?

- They require only standard drills and taps for installation.

- They can be used in most materials, including magnesium, aluminium, carbon & stainless steel, cast iron and plastic.

- They offer simple installation compared to helical wire inserts.

- These inserts prevent turning of the insert after installation.

- They prevent cross-threading while installing.

- These solid inserts are not required to hold the insert in place.

- They are rarely affected by cold or hot temperatures as held in place mechanically and can be easily removed.

Why precision thread helical inserts are used?

Precision inserts are utilised when other techniques of fixing a threaded hole are cumbersome, impractical or impossible. Nearly all threaded fasteners come with minor errors in the threaded form's pitch which tend to focus the stress on a few threads. The helical thread insert's free coils may bend to suit differences in shape and pitch, spreading the load among all threads effectively.

How to install thread inserts?

- To create a new, strong thread, clean up the original, damaged threads with a standard drill (not sold with kits).

- The hole is then tapped with an oversize tap provided in each kit.

- Once in place, the insert tends to spring back to its original diameter, giving it a strong grip in the hole.

- Finally, the driving tang is broken off by tapping downward with the end of the inserting tool.

- If necessary, inserts can be removed using one of the extracting tools.