These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

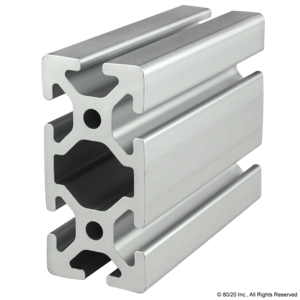

80/20 40-4080-4M Extrusion, 6 Open T-Slot, 4m Length, 80mm Height, Aluminum, Clear

Payment

Delivery

Product Specifications:

| Item | Framing Extrusion |

| Bore Dia. | 6.8mm |

| Color | Clear |

| Drop Lock | 2 Deg. |

| Finish | Anodize |

| Grade | 6105-T5 |

| Height | 80mm |

| Length | 4m |

| Material | Aluminum |

| Modulus Of Elasticity | 70326.5 N/sq. mm |

| Moment Of Inertia - Ix | 97.6617 cm4 |

| Moment Of Inertia - Iy | 25.2917 cm4 |

| Slot Width | 8.12mm |

| Surface Area | 15.332 sq. cm |

| Type | T-Slotted |

| Weight/ft. | 2.743 Lb. |

| Width | 40mm |

| Yield Strength | 241.1 N/ sq. mm |

Shipping Info:

| HS code | 7604210000 |

| Country of Origin | US |

Product Details:

80/20 40-4080-4M framing extrusion is ideal for machine guarding, factory automation, workstations, enclosures, carts, shelving, displays and machine frames.

Features:

- It has a drop-lock & 6 open slots for holding bars together tightly.

- This framing extrusion features 6105-T5 aluminium construction with clear anodised finish for resisting corrosion on exposed surfaces.

Frequently Asked Questions:

Q. How do you install a framing extrusion?

A.

- Plan the location and orientation of the extrusion pieces for creating window / door systems.

- Measure and cut the pieces to the appropriate length by using a carbide-tipped saw.

- Assemble the pieces by using appropriate hardware like brackets, gussets and fasteners.

- Secure the assembly to the desired location and install them using fasteners, such as screws or bolts.

- Install any additional components needed for specific applications, including panels or other accessories.

Q. How do you cut a framing extrusion?

A. There are several ways to cut aluminium framing extrusion. However, the user must ensure that the right blade is used for the job. Some common methods include:

- Mitter saw: This tool is also known as a chop saw and uses a circular blade to cut longer pieces of aluminium extrusion.

- Hack saw: This manual saw has a fine-toothed blade that allows cutting smaller pieces of extrusion.

- Circular saw: This saw uses a blade specifically designed for cutting aluminium, as well as extrusion in longer pieces for specific applications.

Q. How do you finish a framing extrusion?

A. Finishing of aluminium framing extrusion involves cleaning and protecting the surface to improve its appearance, as well as prevent corrosion. Several surface finishes used for the process are:

- Cleaning: Use a mild detergent or degreaser to remove any dirt, dust or oil from the surface of the extrusion.

- Sanding: Use fine-grit sandpaper to smooth out the rough edges or surfaces, providing a smooth, uniform finish.

- Anodising: Anodising is a process of creating a protective oxide layer on the surface to provide excellent corrosion resistance.

- Painting: This will give the extrusion a clean look. Use the paint specifically designed for aluminium, as the other paint may not adhere properly.

- Powder coating: This process involves applying dry powder coating to the surface and then curing with heat, creating a durable and long-lasting finish.

- Polishing: Polishing creates shiny, mirror-like finish on the surface extrusion. This can be done by using a buffing wheel and polishing compounds.

Explore Products

- JOMAR VALVE 900-16DSVG BFV-Wafer Viton

- MILTON-INDUSTRIES 760 V Style Highflowpro Plug, Male, Size 1/4 Inch, Brass, Pack of 10

- GRAINGER 2AU23B/UV-1" X 300' Film Tape, UV-Resistant, Blue, 1 Inch x 100 yd, 2 mil Tape Thick, Multi-Polymer Film

- VEGA TOOLS 125TS06-TI Insert Bit, Torq Set, 6 Tip Size, 1 Inch Length, TiN

- TB WOODS BK301 FHPBoredtosize V-Belt Sheave, Cast Iron, 4L Type Belt, 1.8125 inch Hub Dia.

- SMC VALVES SQ1B31-51-C4 Valve, 3 Port Size

- MAIN FILTER INC. MF0641684 PT23342MPG Interchange Hydraulic Filter, Glass, 10 Micron, Viton Seal, 9.21 Inch Height

- ANVIL 0390080489 6 X 4 E Gasket Only For 7010

Popular Search Queries

Explore More

- CABOT

- CALPIPE SECURITY BOLLARDS

- KEYSHAFT

- CALBRITE

- SIMMONS

- Air Impact Wrenches

- Wall Switches

- Dry Vinyl Plating Tapes

- Electronic Torque Meters

- Insulated Channel Strip Heaters

- AKRO-MILS 35300 Nest And Stack Totes

- LOUISVILLE AE2100 Series Aluminum Single Ladders

- VIEGA PROPRESS Union Zero Lead Bronze Press x Press

- ASSOCIATED SPRING RAYMOND M2 Gas Springs

- AMERICAN TORCH TIP Knurled Screws

- VERMONT GAGE Standard Long Length Drill Blanks, Inch Fractional Sizes, 12 Inch Long

- REESE Pin and Clips

- SMC VALVES Sub Plate

- KIMBLE CHASE Clear Glass Boston Round Bottles

Contact us

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.