These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- HVAC and Refrigeration

- HVAC Controls

- Duct Pressure Switches

Duct Pressure Switches

Switch Air Sensing

| Style | Model | Depth | Function | Height | Switch Type | Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | RSS-495-11 | €33.37 | ||||||

| A | RSS-498-13 | €36.59 | ||||||

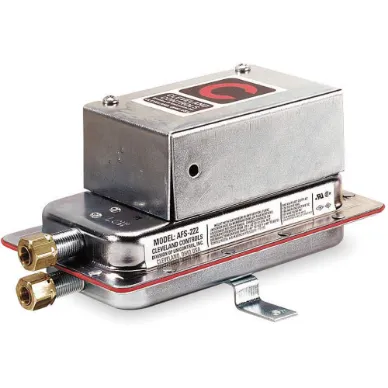

| B | AFS-222 | €48.31 | ||||||

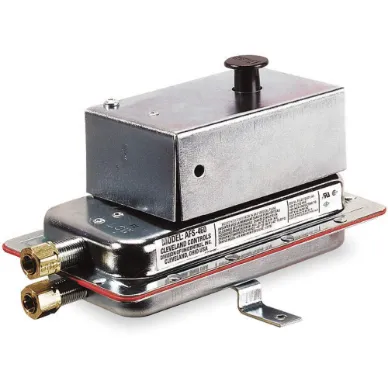

| B | AFS-405 | €68.65 | ||||||

| C | AFS-460 | €68.03 |

Air Flow Switches

2374 Series Air Pressure Sensing Switches

Duct Pressure Switches

| Style | Model | Item | Price (ex. VAT) | |

|---|---|---|---|---|

| A | NS2-1110-02 | €141.56 | ||

| B | AFS-460-137 | €183.29 | ||

| C | RSS-495-11 | €39.90 | ||

| D | AFS-262 | €207.52 | ||

| E | AFS-952 | €837.72 | ||

| F | AFS-227-161 | €116.20 | ||

| G | AFS-952-1 | €1,858.17 | ||

| H | AFS-A | €75.97 | ||

| I | AFS-298-112-147 | €85.60 | ||

| J | DFS-221 | €57.45 | ||

| K | AFS-A-173 | €77.96 | ||

| L | AFS-271 | €73.70 | ||

| C | RSS-498-13 | €44.68 | ||

| M | AFS-460-112 | €216.41 | ||

| A | AFS-442 | €86.34 | ||

| N | NS2-0000-00 | €40.41 | ||

| N | NS2-0000-01 | €39.21 | ||

| D | AFS-262-121 | €86.75 | ||

| I | AFS-275-112 | €63.52 | ||

| O | AFS-262-112 | €133.40 | ||

| P | AFS-145 | €120.06 | ||

| Q | AFS-222-136 | €157.61 | ||

| O | AFS-222-112 | €124.51 | ||

| R | AFS-228 | €63.52 | ||

| E | AFS-953 | €895.38 |

Duct Pressure Switches

Pressure Sensing Switches

Air Sensing Switches

Air Sensing Switches

| Style | Model | Depth | Height | Type | Width | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|

| A | RFS-4150 | €43.11 | |||||

| B | NS2-0000-05 | €29.07 | |||||

| C | DFS-221-112-395 | €39.87 |

Duct Pressure Switches

| Style | Model | Item | Price (ex. VAT) | |

|---|---|---|---|---|

| A | 0130M00132 | €55.98 | ||

| B | B1370208 | €123.28 | ||

| C | 20197311 | €62.22 | ||

| A | 0130F00002P | €57.29 | ||

| A | 0130F00070 | €39.92 | ||

| D | 0130F00068 | €44.02 | ||

| E | 0130M00243 | - | RFQ |

| Style | Model | Type | Price (ex. VAT) | |

|---|---|---|---|---|

| A | ADPS-08-2-N | €46.19 | ||

| A | ADPS-04-2-N | €43.39 | ||

| A | ADPS-03-2-N | €46.04 | ||

| A | ADPS-05-2-N | €33.07 | ||

| A | ADPS-06-2-N | €39.97 | ||

| A | ADPS-07-2-N | €37.98 |

Pressure 120V-277V 15Amp Fanspeed

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 706-123SC | CR4BNH | €184.72 |

Adjustable Air Pressure, SW .1-4 Inch WC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| RSS498013 | CV4KQY | €34.11 |

Air Sensing Switch

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 141-0575 | CU2REJ | €128.79 |

Controls Air Sensing Switch

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 141-0518 | CT7WTG | €106.95 |

Pressure Switch100/400N. 36 Inch Sizecap.Spst

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| P70AA-205 | CR6BAH | €258.79 |

Differential Pressure Switch

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| DPA-7033-153-61 | CP3YDP | €2,552.97 |

Airflow Switch Auto Reset Spdt

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 141-0574 | AC2HML | €120.04 |

Pressure Sensing Switch Adjustable

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| PS2501 | AA6TBJ | €153.65 |

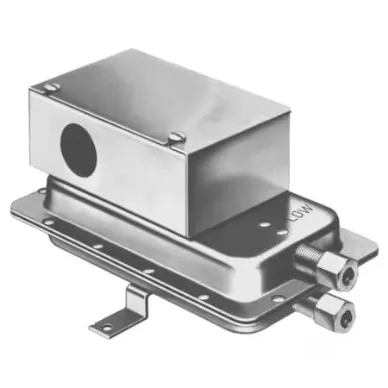

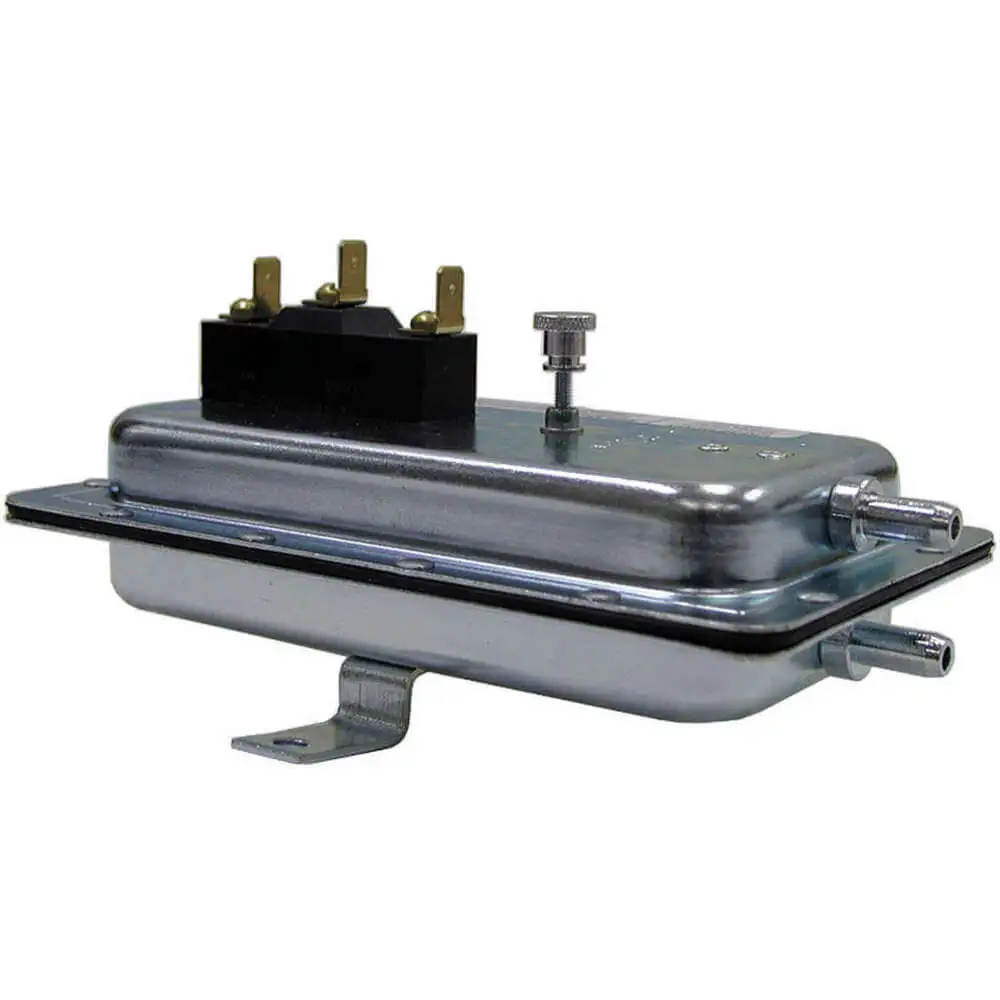

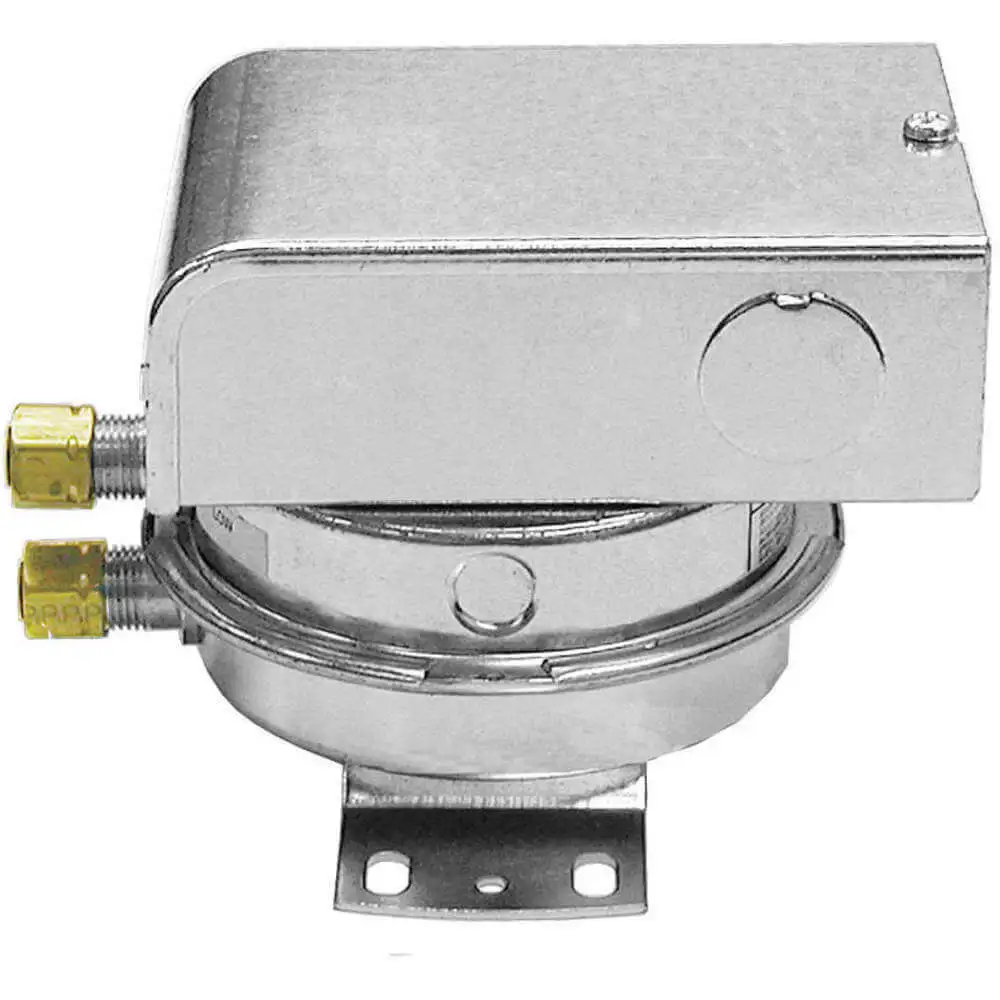

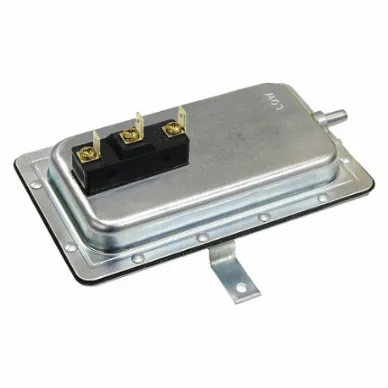

Duct Pressure Switches

Duct pressure switches are designed to utilise differential air pressure to actuate electric switches at a pre-set actuation point. Raptor Supplies offers an array of duct pressure switches from brands like Cleveland Controls, Columbus Electric, Dwyer Instruments, Johnson Controls, Robertshaw, Siemens and Tjernlund. These switches can automatically start and stop auxiliary devices like electronic air cleaners, duct heaters, humidifiers, exhaust fans and duct booster fans. Dwyer Instrumentsduct pressure switches are compatible for use with vacuum and differential pressure supply and have dual scaled adjustment knobs in inch, water column and pascal units which facilitate making changes in the switching pressure without a pressure gage. The ADPS / EDPS variants are offered in settings ranging from 0.08 inch W.C. (20 Pa) to 20 inch W.C. (5000 Pa). The silicone diaphragm and PA 6.6 cobstruction of these switches make them suitable for use with air and other noncombustible gases at extreme temperatures. Johnson Controlsdifferential air pressure switches are used to sense the flow of air in ducts. When these air pressure switches are used with electric strip heaters, they can be wired to open the circuit and de-energise the heaters when the air flow stops. These switches have a small and compact.design with easy-to-read set point scale and are available in SPST NC, SPDT, SPST and SPST NC switch types on Raptor Supplies.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- LISLE

- IMPELLER

- BIG ASS FANS

- Ceiling Exhaust Ventilators

- Parting and Grooving Tools

- Flame Retardant Gloves

- Plungers

- Light Meters

- BANJO Anti Vortex Vent Caps

- DAYTON Push Button Operators, Momentary Push

- TRICO Machine Synchronized Unit, Streamliner MSP

- SPEARS VALVES PVC Gray Schedule 40 Fitting Unions, Socket x Socket, EPDM

- DESTACO 374-M Series Pull Action Latch Clamps