These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Hand Tools

- Clamps

- Vertical Handle Toggle Clamps

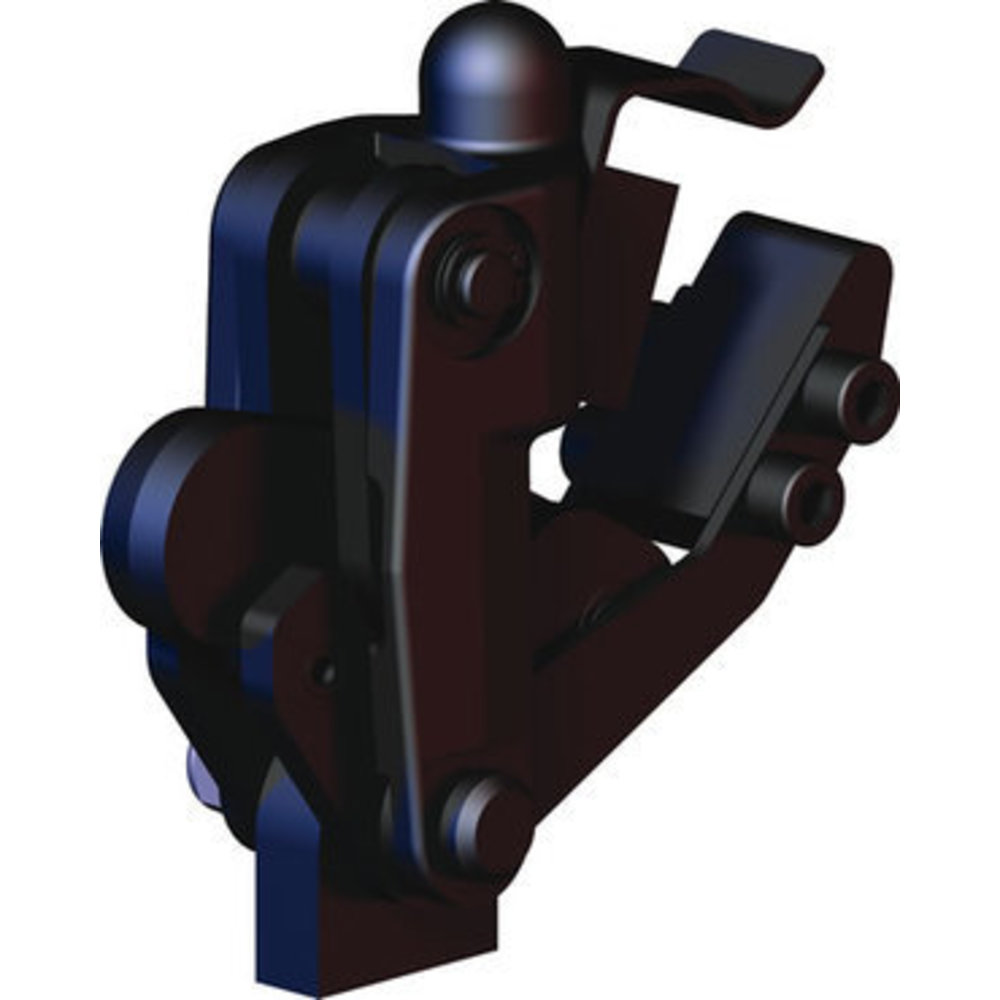

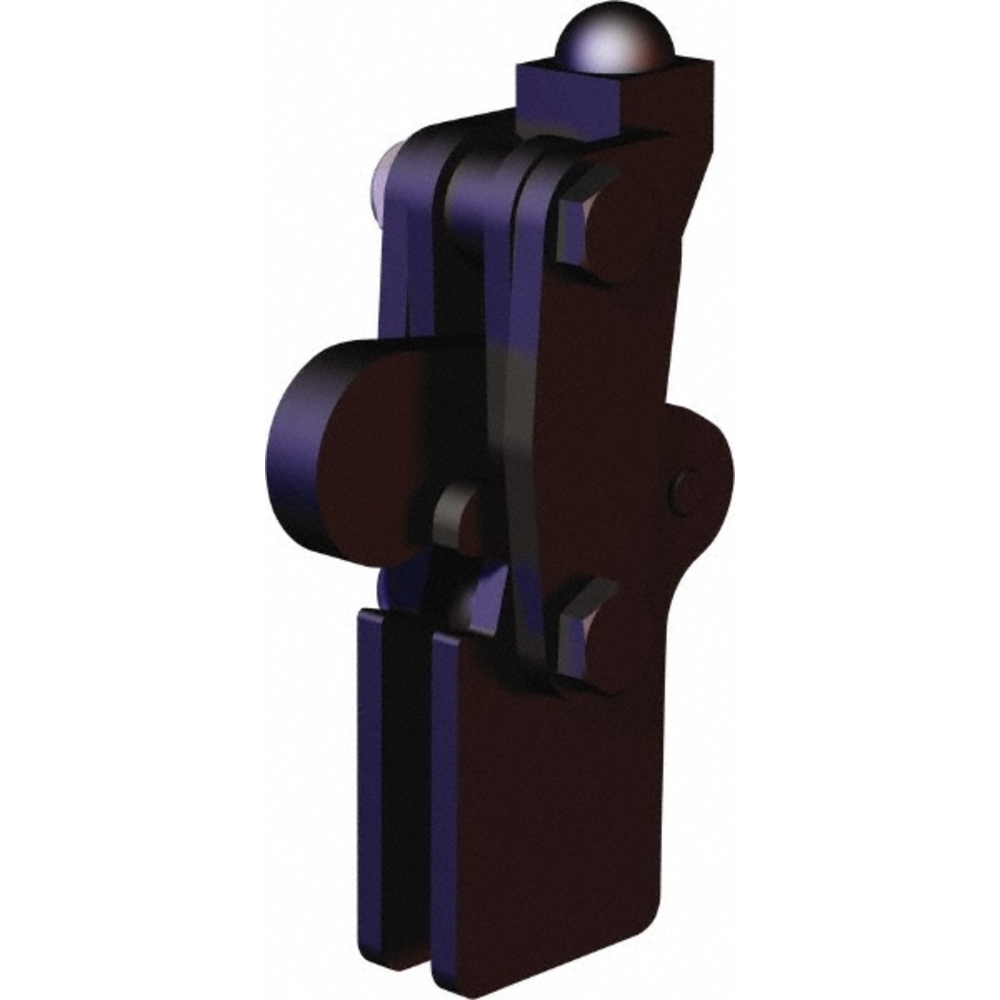

Vertical Handle Toggle Clamps

Vertical handle toggle clamps are mechanical devices that securely hold objects in place during cutting, welding or machining processes. They are useful in the woodworking, metalworking and...Read more

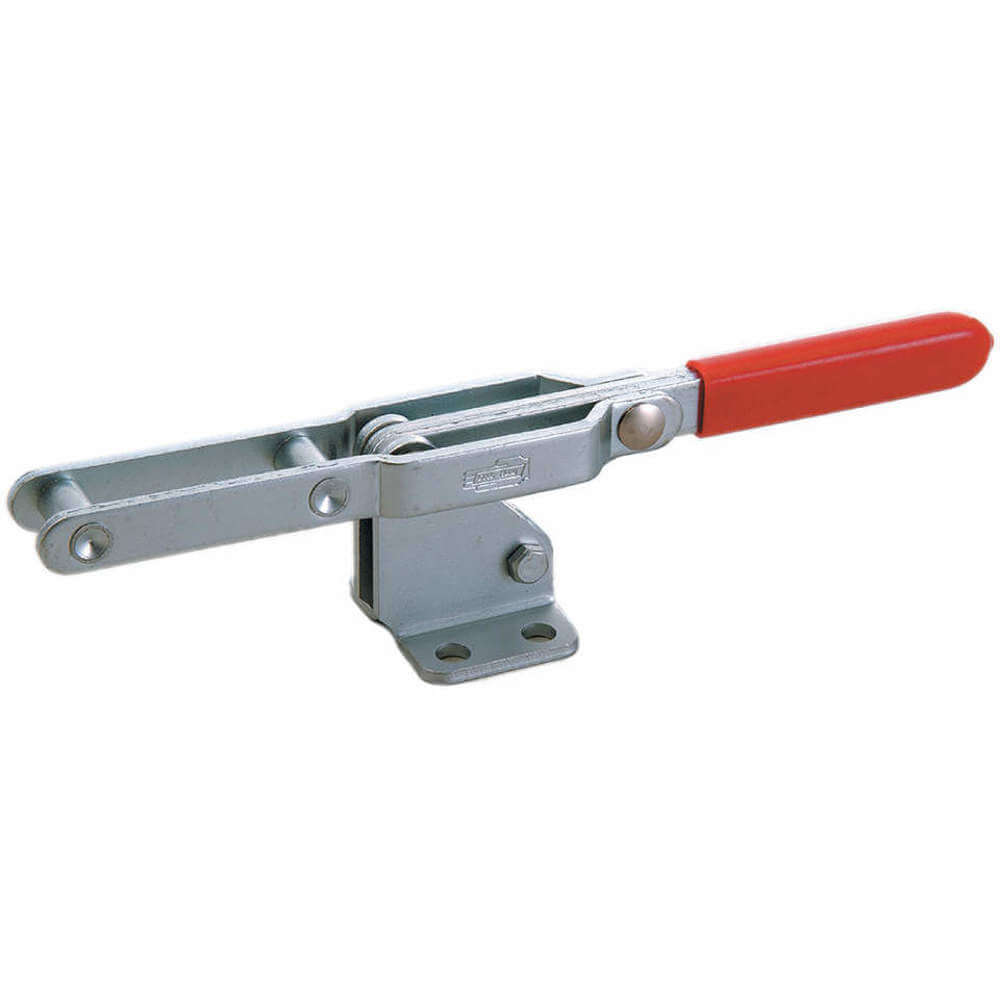

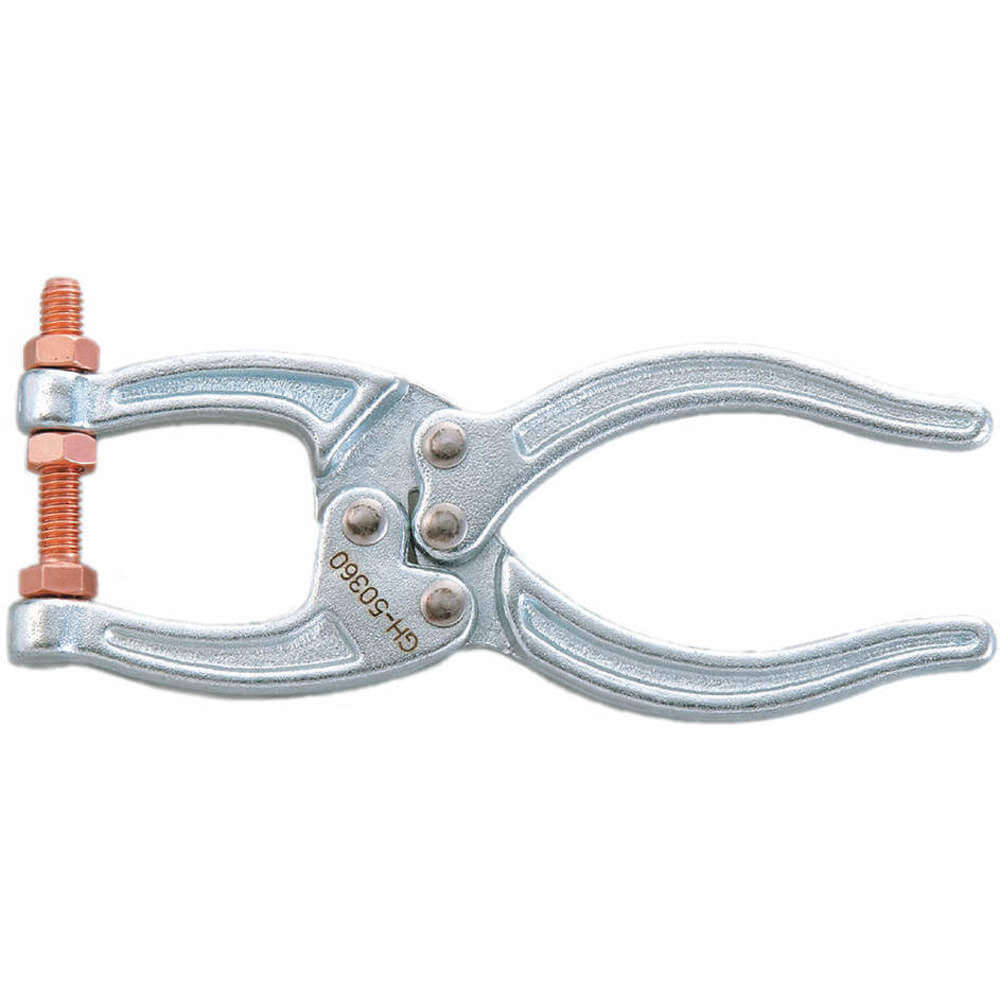

324 Series Pull Action Latch Clamps

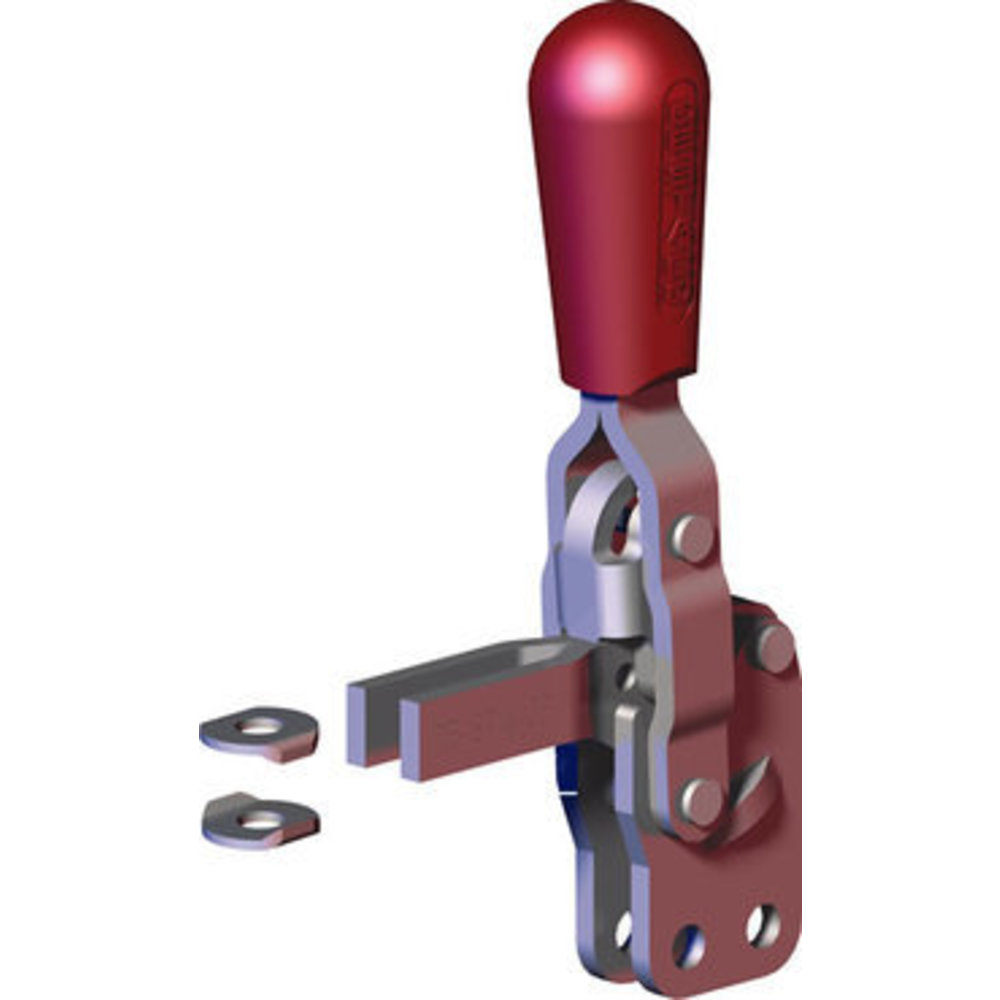

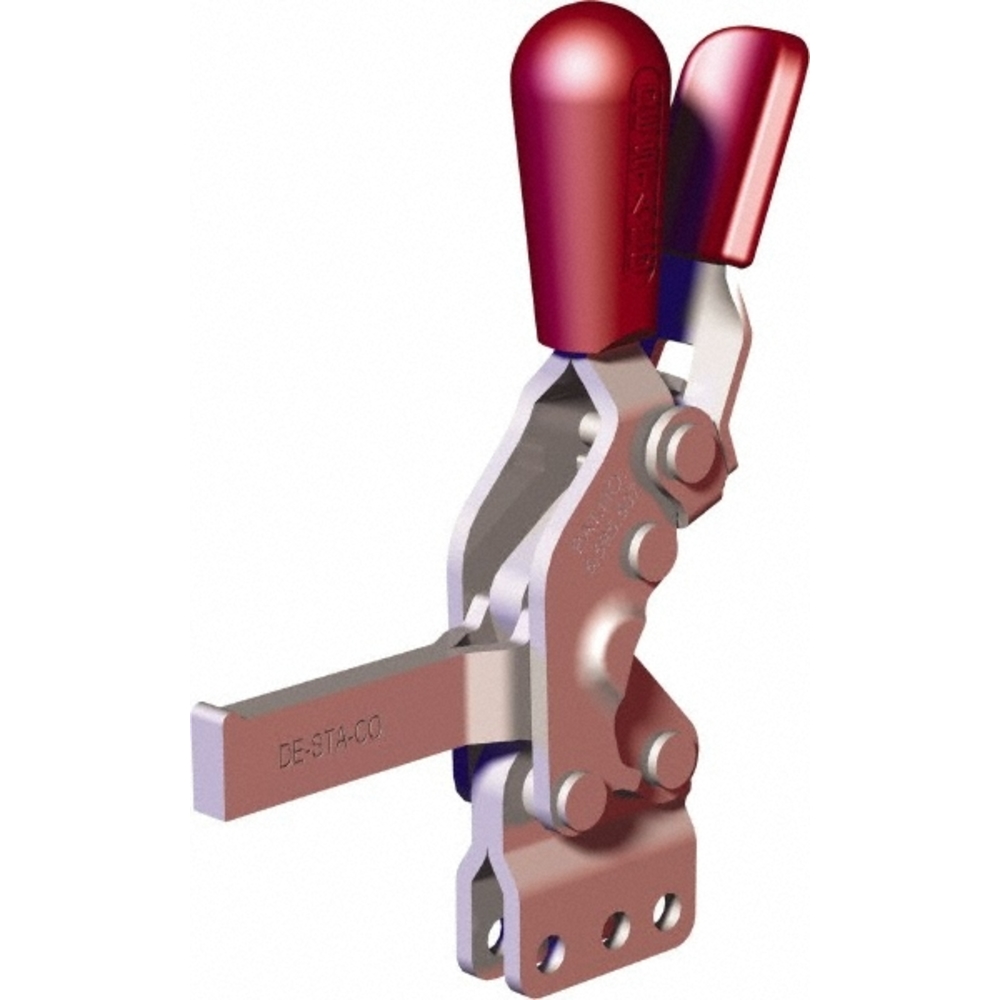

201 Series Vertical Hold Down Clamps

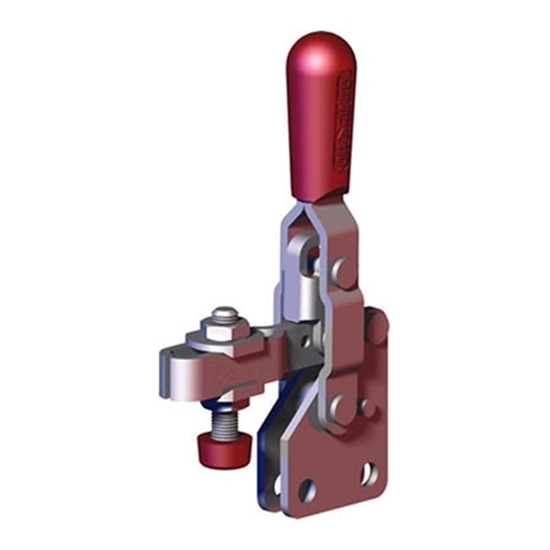

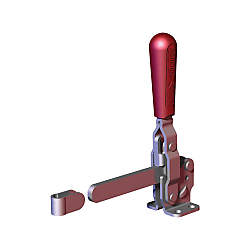

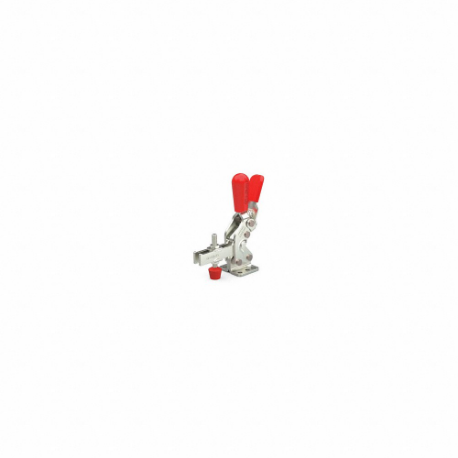

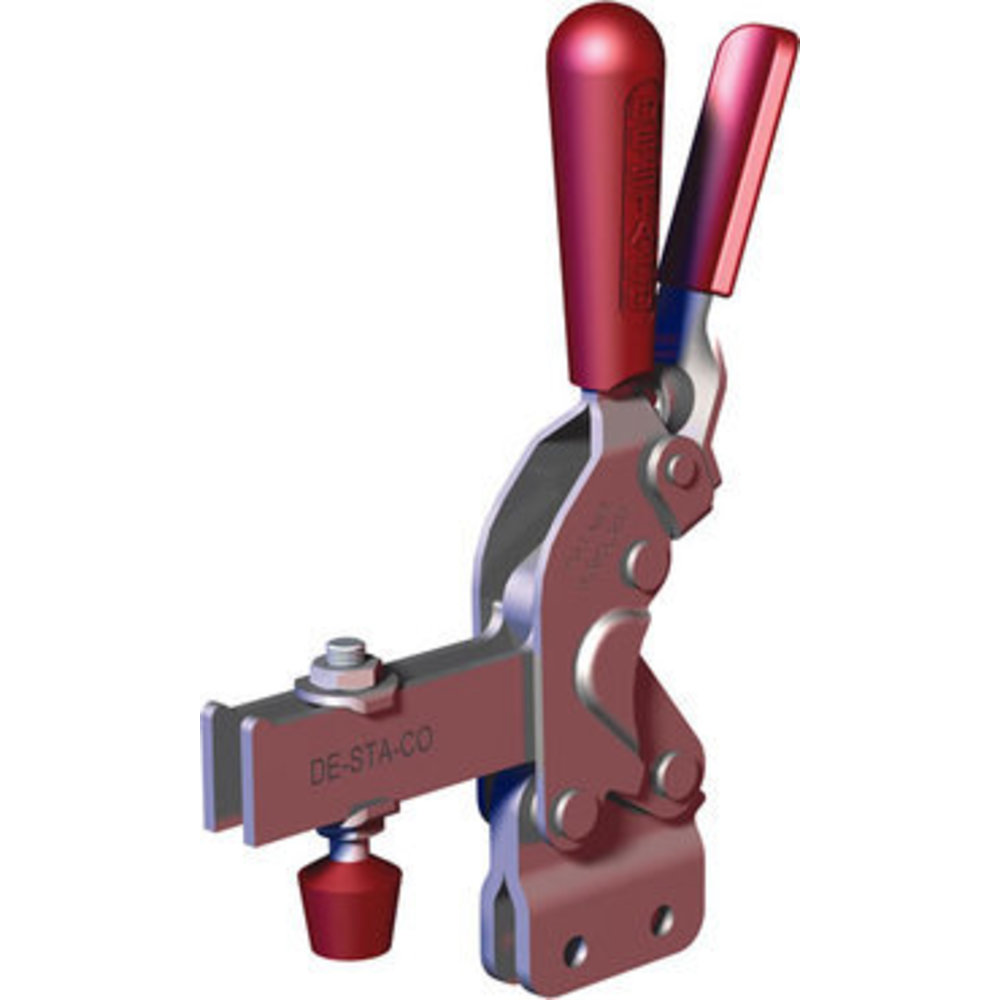

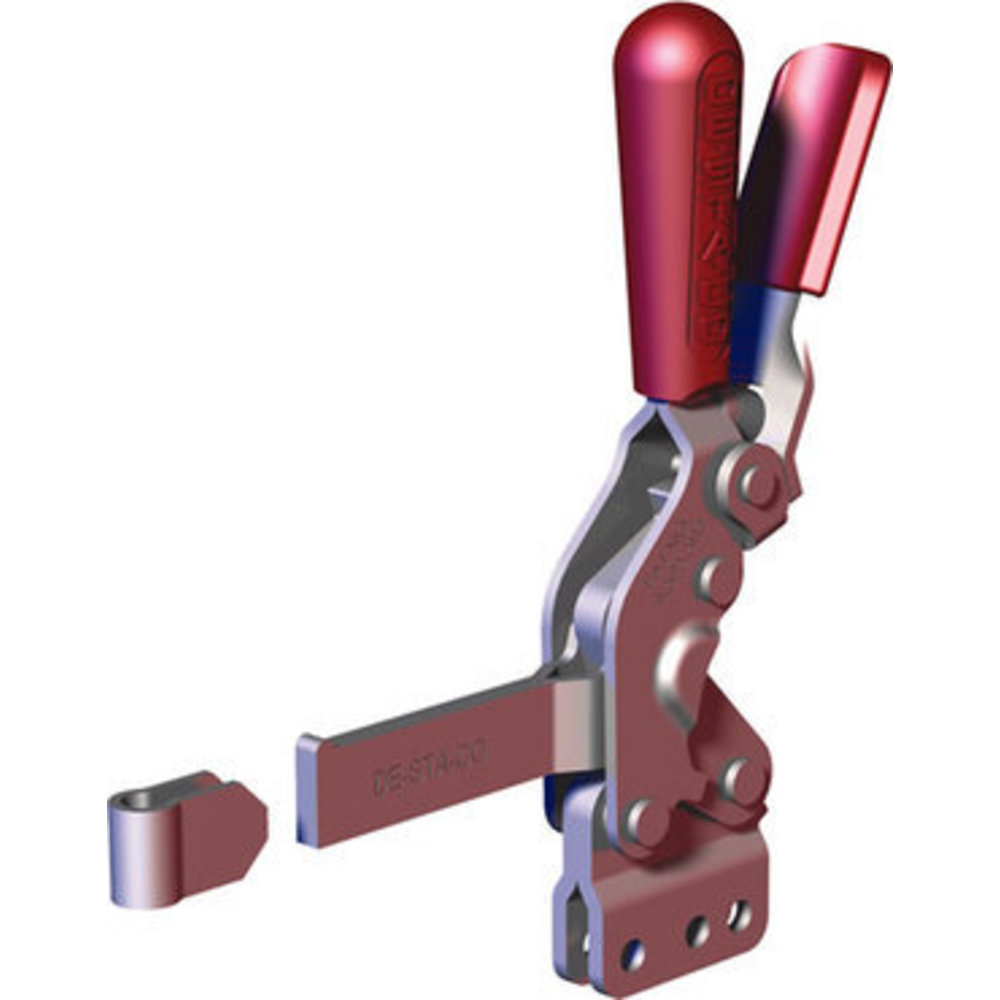

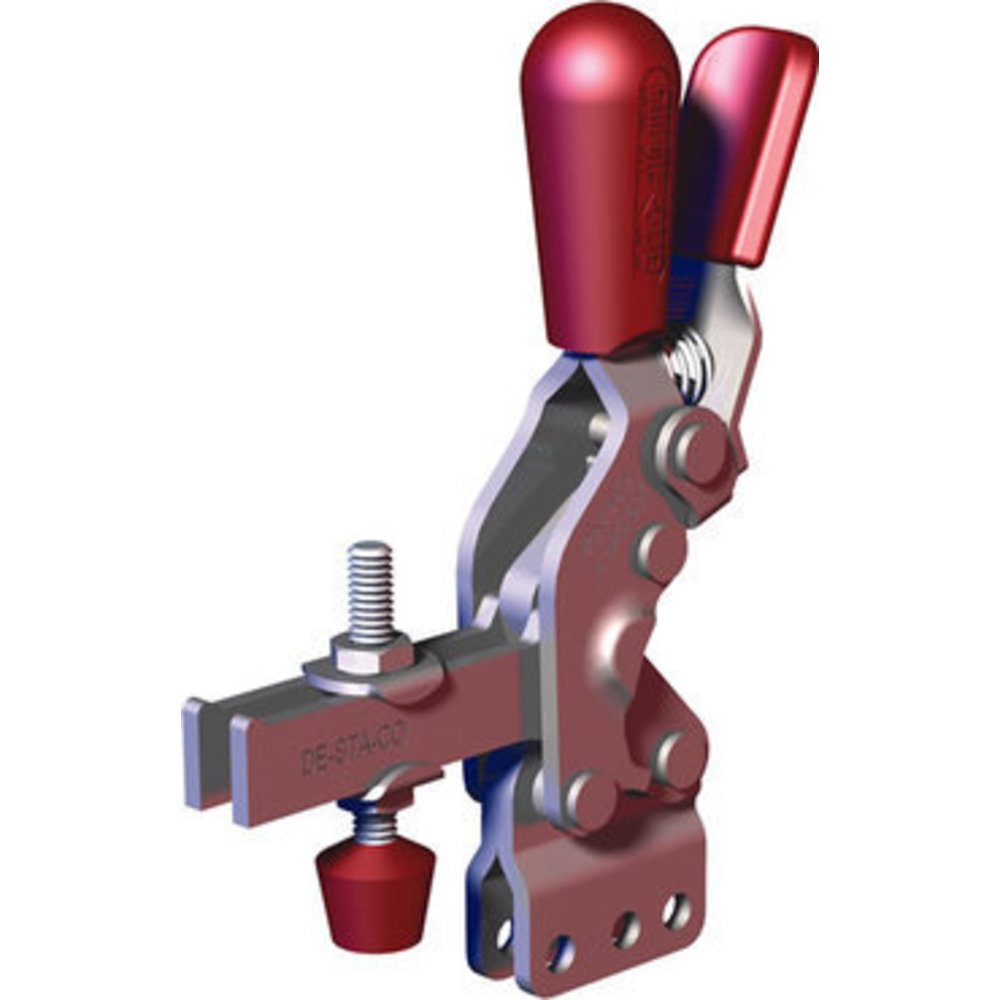

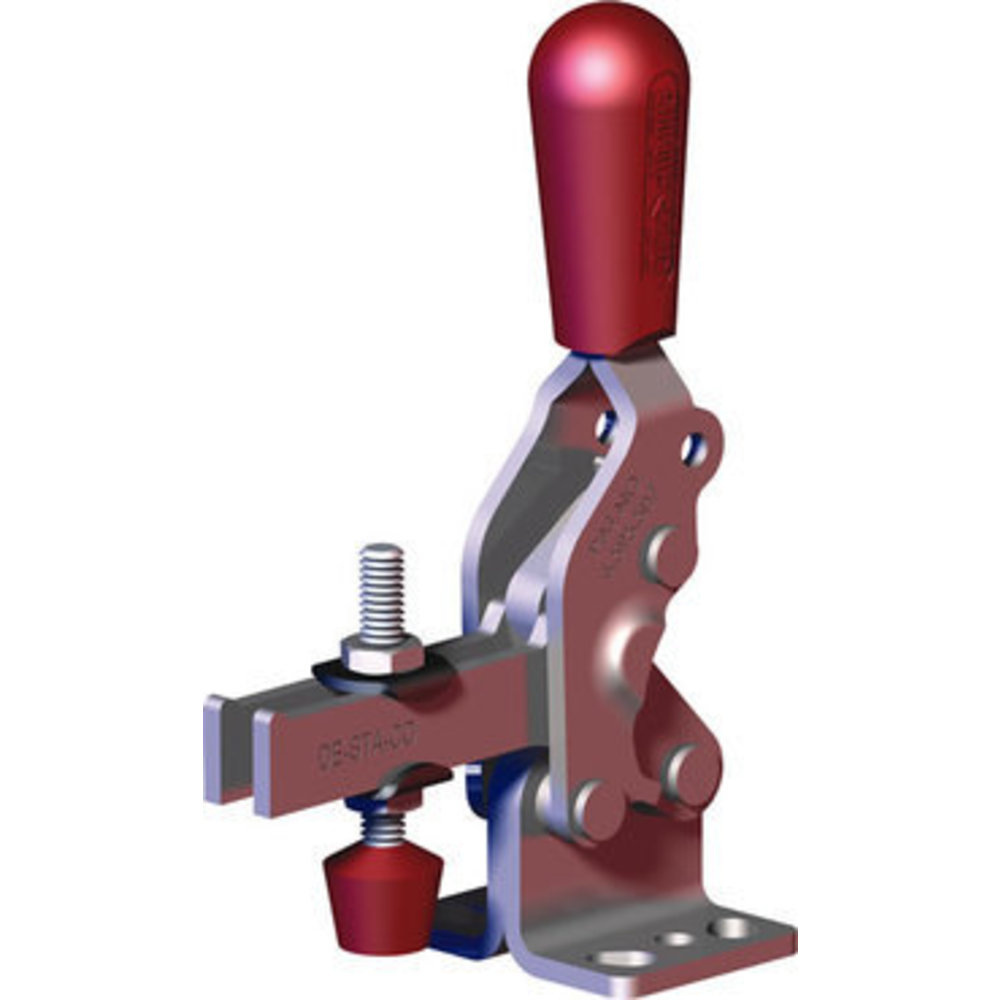

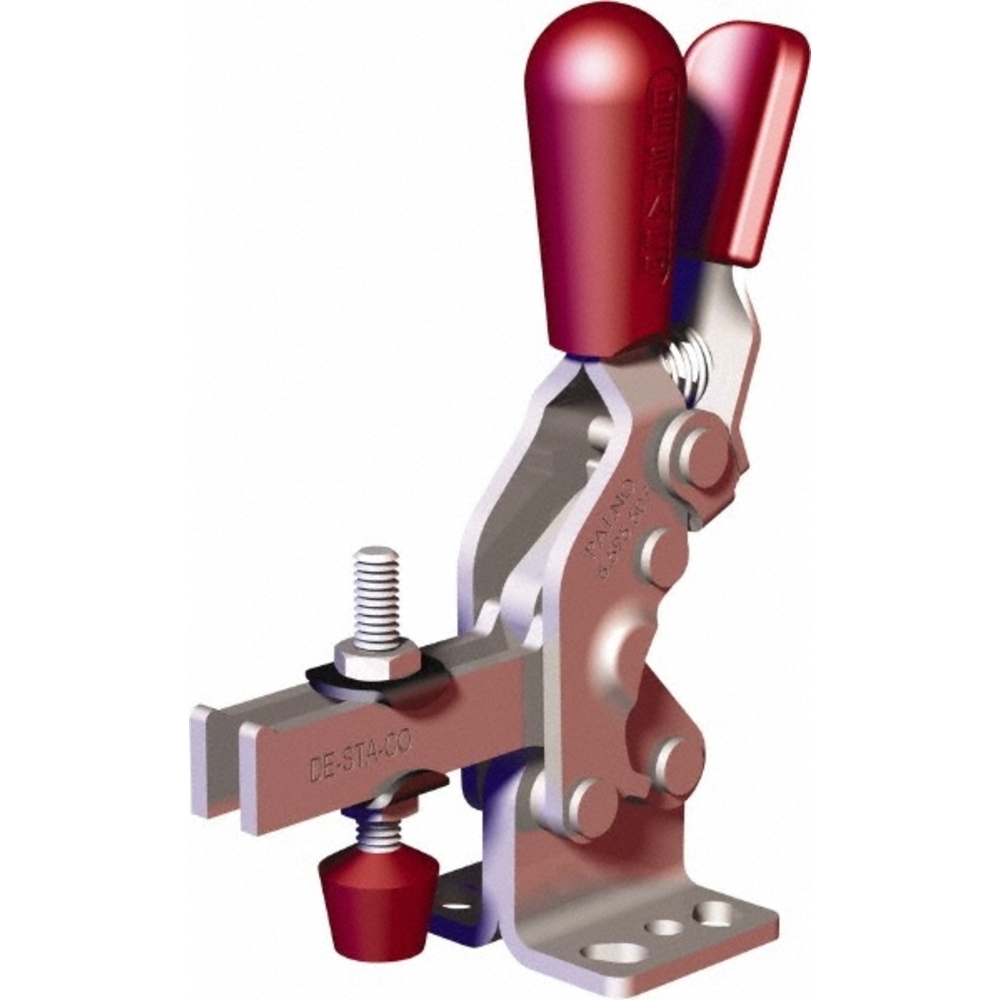

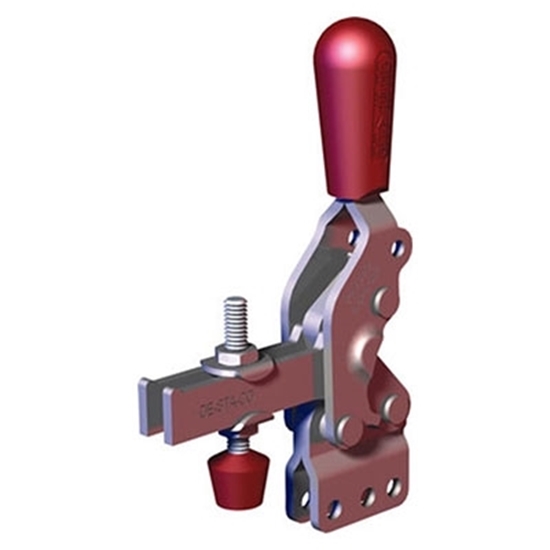

These Destaco 201 Series vertical hold down toggle locking clamps, also known as vertical manual hold down clamps, are designed to offer a stationary alternative to removable C clamps or spring clamps when securing materials to a work surface. These manual clamps hold workpieces in place using a lever handle that is pushed to the upright position when the clamps are engaged. Further, they apply downward clamping force by increasing the applied load via toggle mechanisms and are ideal for fixture checking, assembling / testing, woodworking and light machining in the aerospace, automotive and food & packaging industries. These hold down clamps feature a low profile design for tight spaces and offer the flexibility to position the base, clamp arm & handle by welding them in the desired position. They comprise accurately machined components having hardened & ground pivot pins & bushings. These clamps are supplied with a neoprene spindle for maximum holding force and ergonomic handle grip. Destaco vertical manual hold down clamps feature a straight or flanged base with threaded holes for ease of installation. These weldable vertical toggle clamps provide the flexibility to position the handle as required and feature a fatigue less handle grip. These vertical hold down clamps are made of steel / stainless steel for resisting corrosion on exposed surfaces and are capable of withstanding loads up to 125 lb. Additionally, they have a flanged or straight base with threaded holes for quick & secure surface or blade mounting, respectively. These clamps offer great hand clearance and can exhibit a maximum clamp bar opening angle of 100 degrees.

These Destaco 201 Series vertical hold down toggle locking clamps, also known as vertical manual hold down clamps, are designed to offer a stationary alternative to removable C clamps or spring clamps when securing materials to a work surface. These manual clamps hold workpieces in place using a lever handle that is pushed to the upright position when the clamps are engaged. Further, they apply downward clamping force by increasing the applied load via toggle mechanisms and are ideal for fixture checking, assembling / testing, woodworking and light machining in the aerospace, automotive and food & packaging industries. These hold down clamps feature a low profile design for tight spaces and offer the flexibility to position the base, clamp arm & handle by welding them in the desired position. They comprise accurately machined components having hardened & ground pivot pins & bushings. These clamps are supplied with a neoprene spindle for maximum holding force and ergonomic handle grip. Destaco vertical manual hold down clamps feature a straight or flanged base with threaded holes for ease of installation. These weldable vertical toggle clamps provide the flexibility to position the handle as required and feature a fatigue less handle grip. These vertical hold down clamps are made of steel / stainless steel for resisting corrosion on exposed surfaces and are capable of withstanding loads up to 125 lb. Additionally, they have a flanged or straight base with threaded holes for quick & secure surface or blade mounting, respectively. These clamps offer great hand clearance and can exhibit a maximum clamp bar opening angle of 100 degrees.

527 Series Vertical Hold Down Clamps

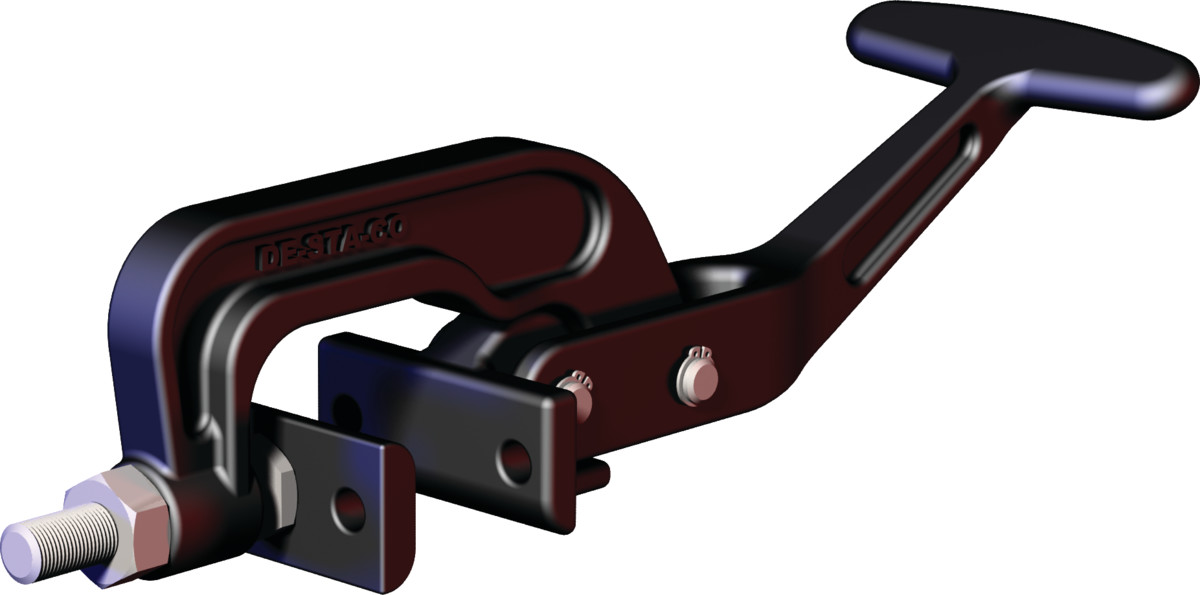

3031, 3051 Series Pull Action Latch Clamps

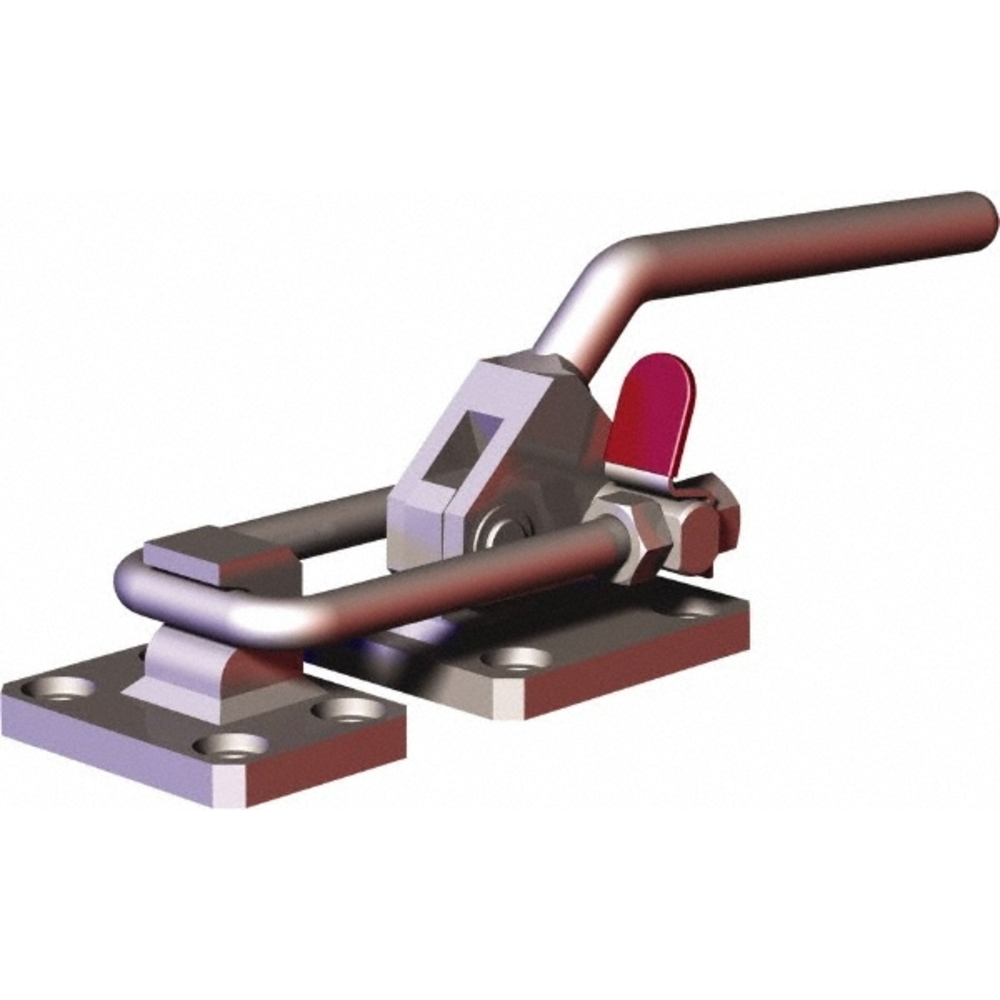

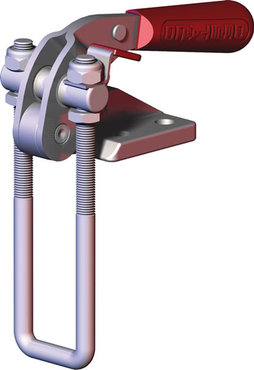

Destaco 3031, 3051 Series pull action latch clamps are well suited for securing & molding closures for lids, doors & covers and also for assembling applications in the automotive, aerospace and food & packaging industries. These pull action latch clamps provide a stationary alternative to removable C clamps or spring clamps while securing material to the work surface and holding them in place using a lever handle that is pushed to the upright position when the clamp is engaged & pressed down to reach the locked position, ensuring fatigue less and quick clamping operations. These pull action latch clamps have a patented thumb control lever for single handed operation. These Destaco 3031, 3051 Series pull action latch clamps feature a flanged base with threaded holes for quick and secure installation. These pull action latch clamps are made of steel for structural rigidity and resisting corrosion on exposed surfaces. These clamp units further provide innovative, controlled hook motion that allows quick, safe and single handed operation. Destaco 3031, 3051 Series pull action latch clamps are capable of withstanding loads up to 1500 lb and offer hook adjustment up to 14 mm. Destaco 3031, 3051 Series pull action latch clamps come with J hook style latches, integrated with threaded J hooks for easy adjustments.

Destaco 3031, 3051 Series pull action latch clamps are well suited for securing & molding closures for lids, doors & covers and also for assembling applications in the automotive, aerospace and food & packaging industries. These pull action latch clamps provide a stationary alternative to removable C clamps or spring clamps while securing material to the work surface and holding them in place using a lever handle that is pushed to the upright position when the clamp is engaged & pressed down to reach the locked position, ensuring fatigue less and quick clamping operations. These pull action latch clamps have a patented thumb control lever for single handed operation. These Destaco 3031, 3051 Series pull action latch clamps feature a flanged base with threaded holes for quick and secure installation. These pull action latch clamps are made of steel for structural rigidity and resisting corrosion on exposed surfaces. These clamp units further provide innovative, controlled hook motion that allows quick, safe and single handed operation. Destaco 3031, 3051 Series pull action latch clamps are capable of withstanding loads up to 1500 lb and offer hook adjustment up to 14 mm. Destaco 3031, 3051 Series pull action latch clamps come with J hook style latches, integrated with threaded J hooks for easy adjustments.

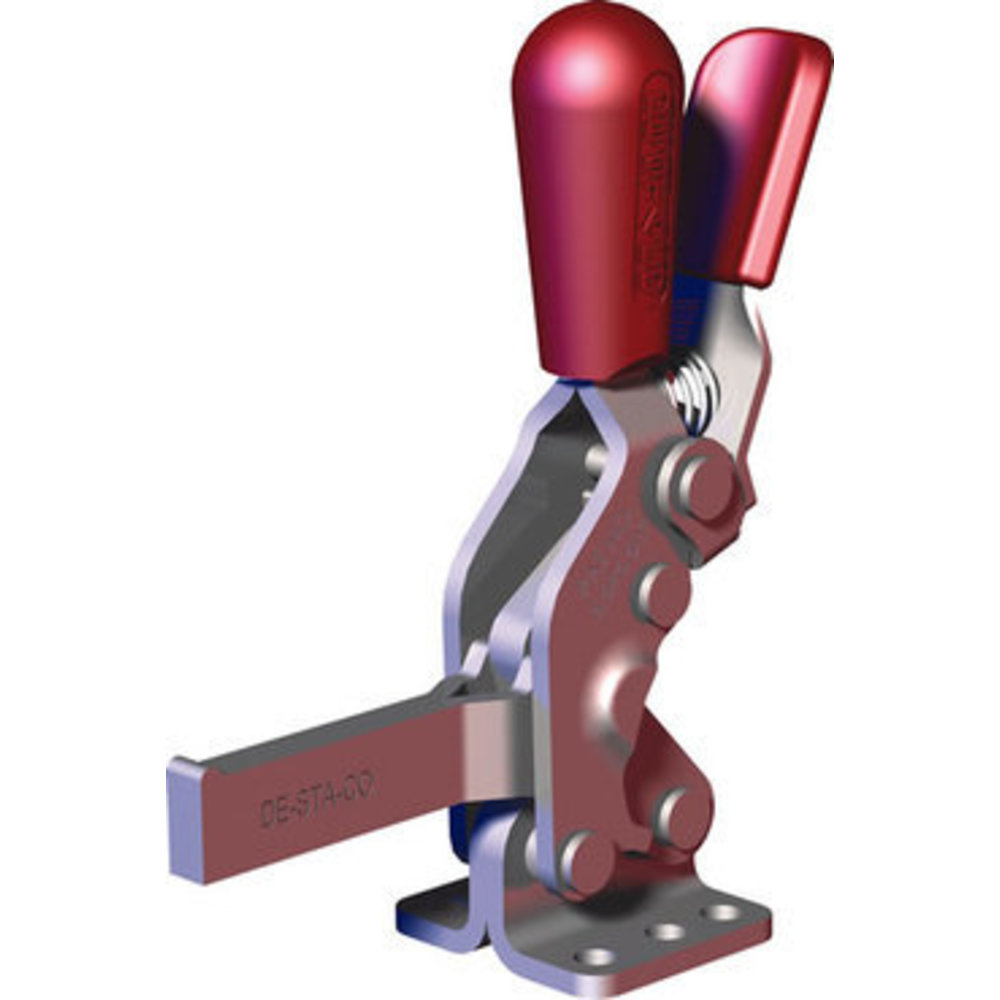

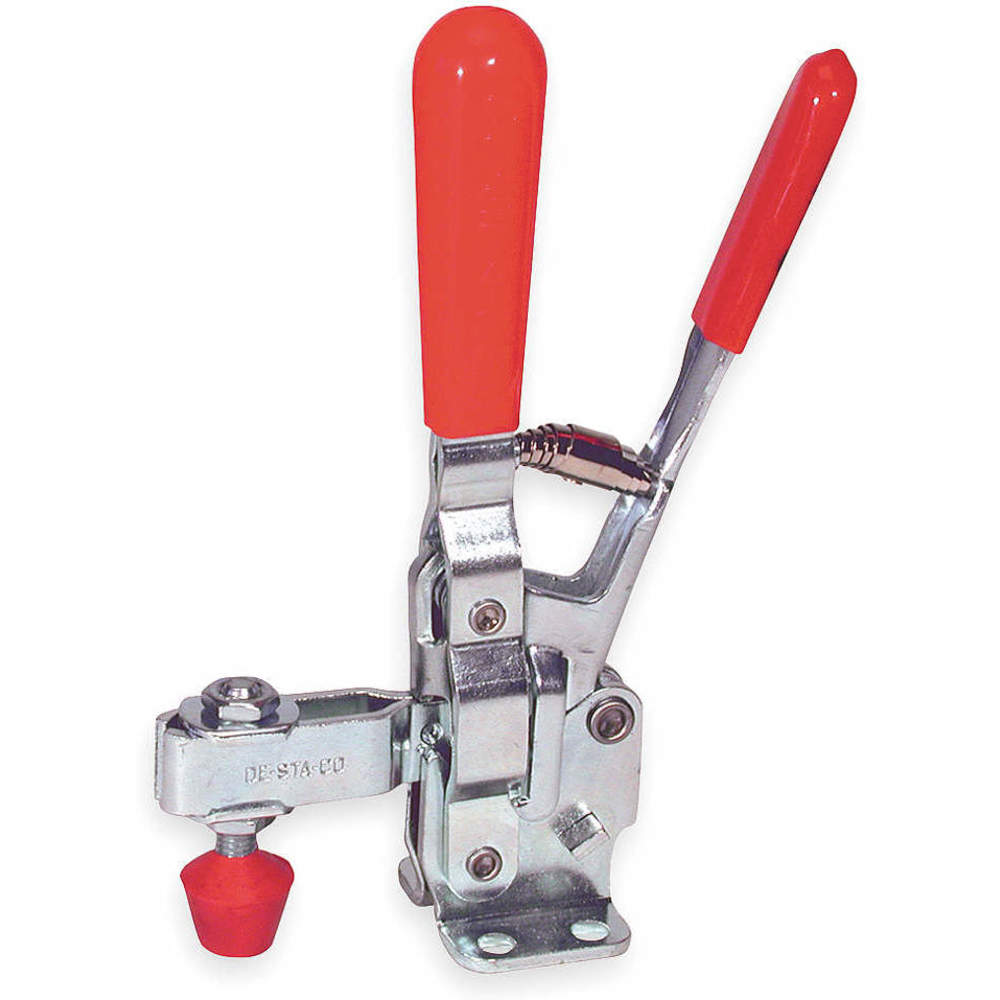

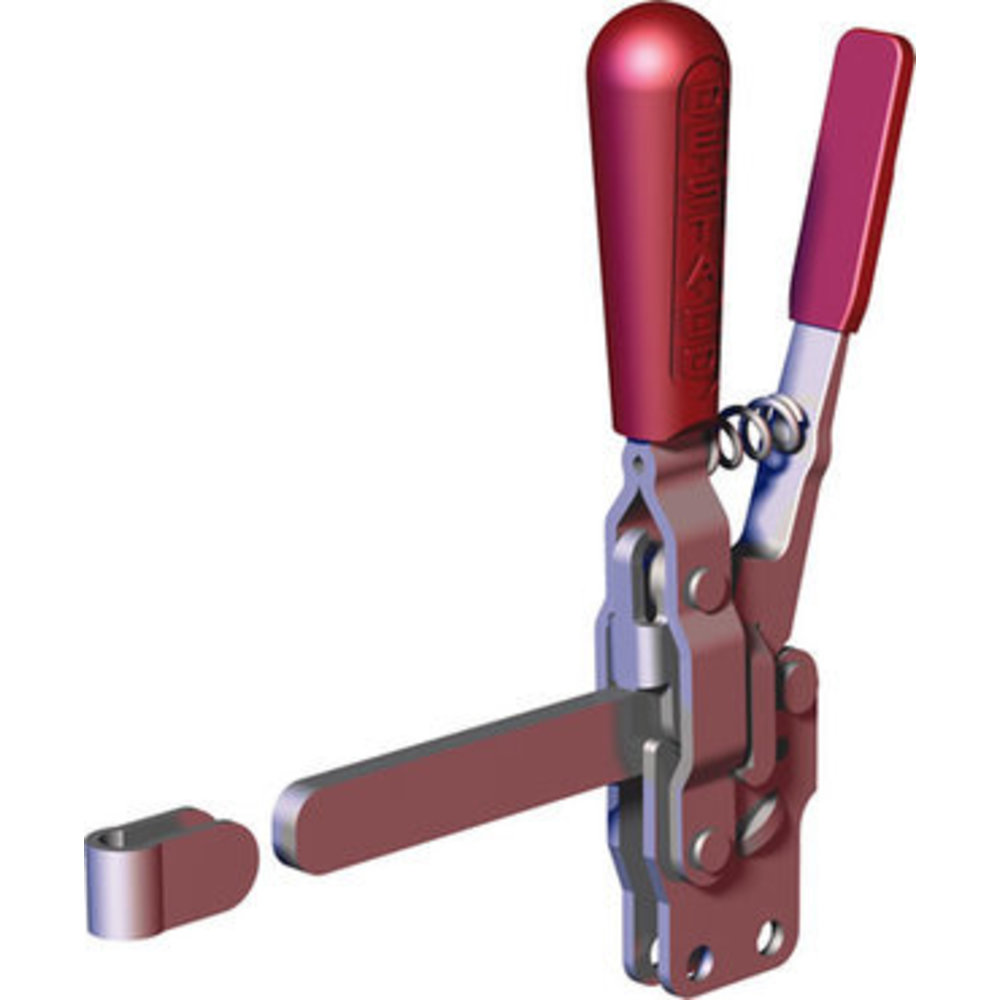

247, 267 Series Vertical Hold Down Clamps

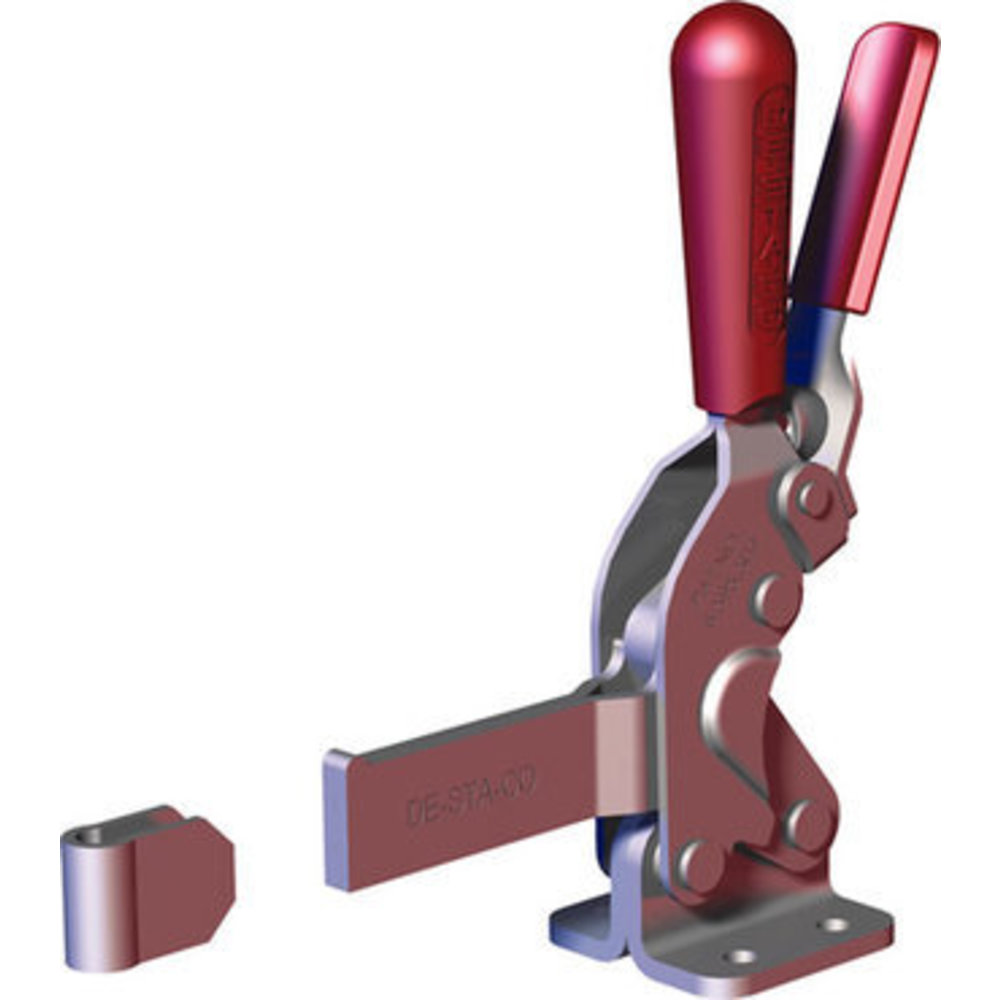

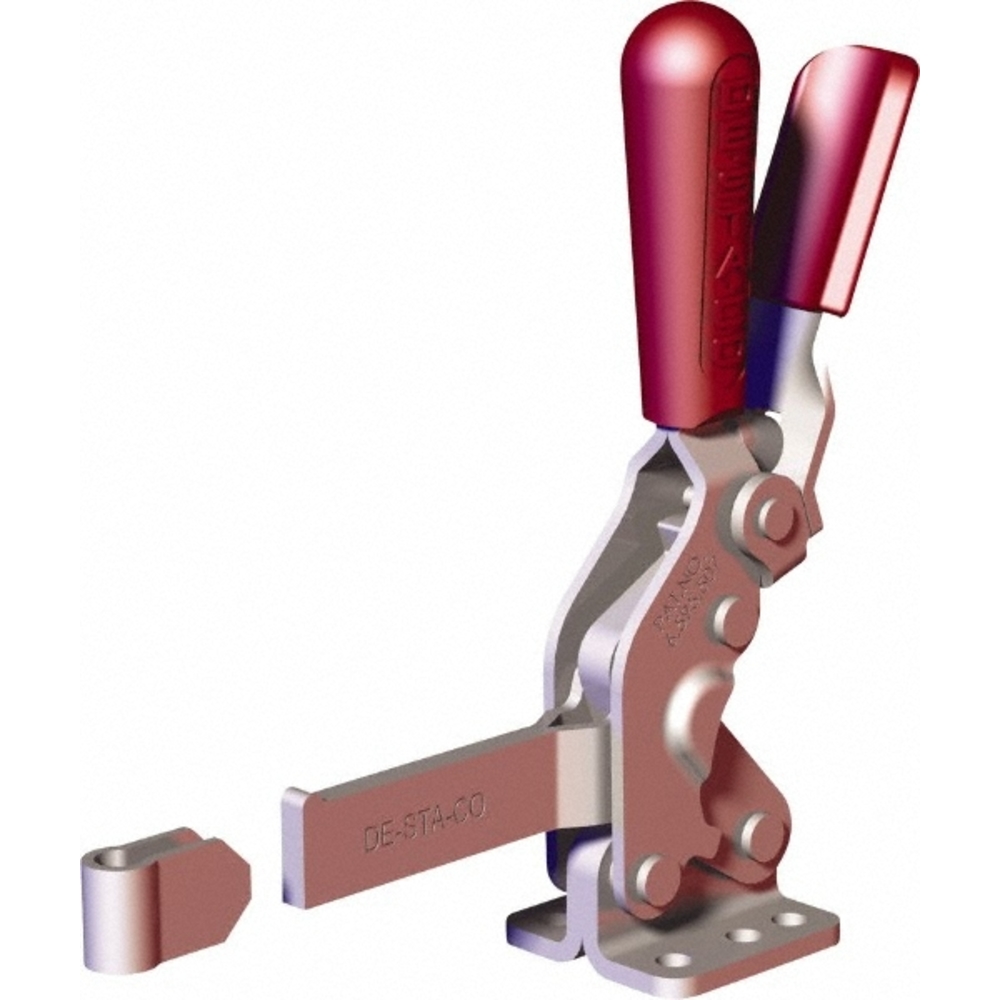

These Destaco 247 & 267 Series vertical hold down clamps are designed to apply downward clamping force by increasing the applied load via toggle mechanisms. These clamps offer a stationary alternative to removable C clamps or spring clamps when securing material to a work surface. They comprise precisely machined components having hardened & ground pivot pins & bushings and feature steel construction to resist corrosion.These units have a holding capacity of 1200 lb and feature large bar guides for excellent lateral stability. They hold workpieces in place using a lever handle that is pushed to the upright position when the clamp is engaged. Destaco 247 & 267 Series vertical hold down clamps are used in welding, grinding, machining and metal fabrication applications in the aerospace, automotive and food & packaging industries. These clamps have a flanged or straight base with threaded holes for ease-of-installation and come with an ergonomic handle grip to ensure minimum operator fatigue. Selected models are supplied with neoprene spindles to exhibit chemical stability and for maintaining flexibility over a wide temperature range. These Destaco 247 & 267 Series are available in U bar & solid bar clamping arm variants on Raptor Supplies for adjustable spindle location and to offer customised attachments & fixed clamping, respectively.

These Destaco 247 & 267 Series vertical hold down clamps are designed to apply downward clamping force by increasing the applied load via toggle mechanisms. These clamps offer a stationary alternative to removable C clamps or spring clamps when securing material to a work surface. They comprise precisely machined components having hardened & ground pivot pins & bushings and feature steel construction to resist corrosion.These units have a holding capacity of 1200 lb and feature large bar guides for excellent lateral stability. They hold workpieces in place using a lever handle that is pushed to the upright position when the clamp is engaged. Destaco 247 & 267 Series vertical hold down clamps are used in welding, grinding, machining and metal fabrication applications in the aerospace, automotive and food & packaging industries. These clamps have a flanged or straight base with threaded holes for ease-of-installation and come with an ergonomic handle grip to ensure minimum operator fatigue. Selected models are supplied with neoprene spindles to exhibit chemical stability and for maintaining flexibility over a wide temperature range. These Destaco 247 & 267 Series are available in U bar & solid bar clamping arm variants on Raptor Supplies for adjustable spindle location and to offer customised attachments & fixed clamping, respectively.

7-101, 7-58, 7-59, 7-60 Heavy Duty Cam Action Series

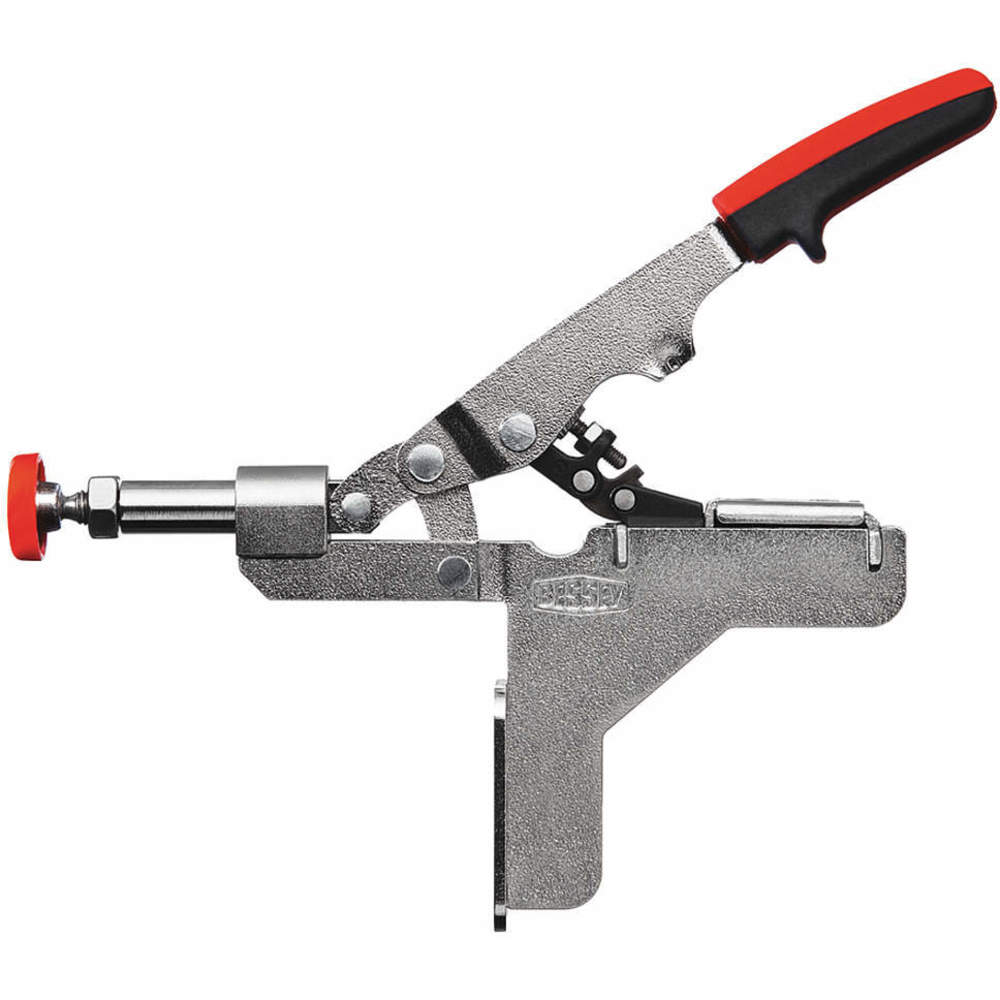

Auto-adjust Toggle Clamp

202 Series Vertical Hold Down Clamps

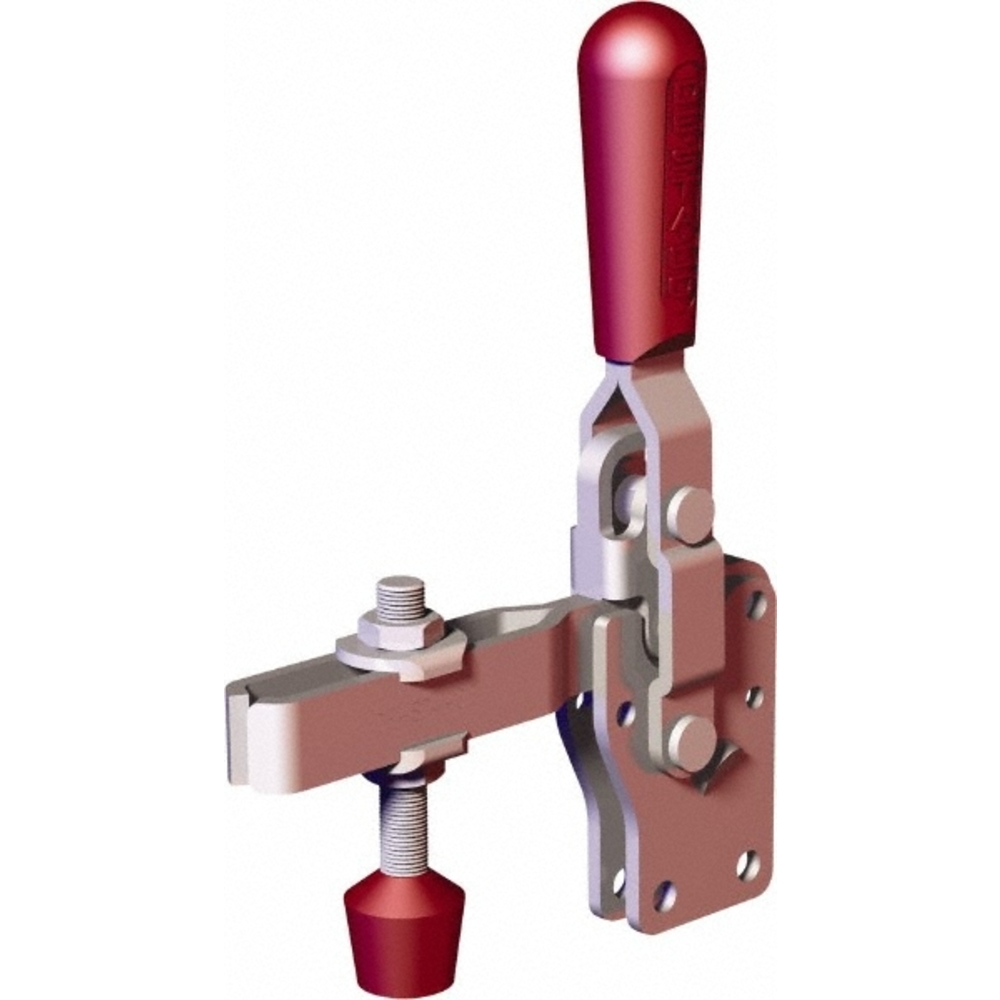

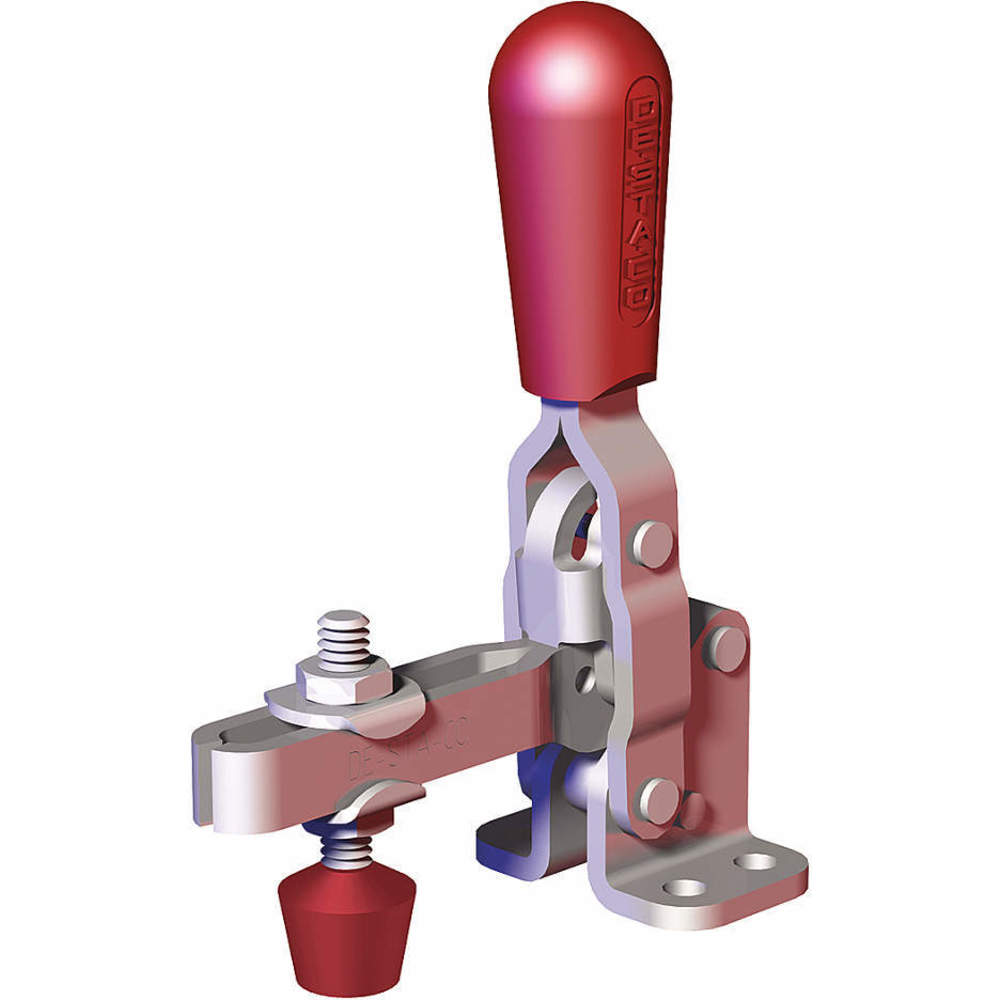

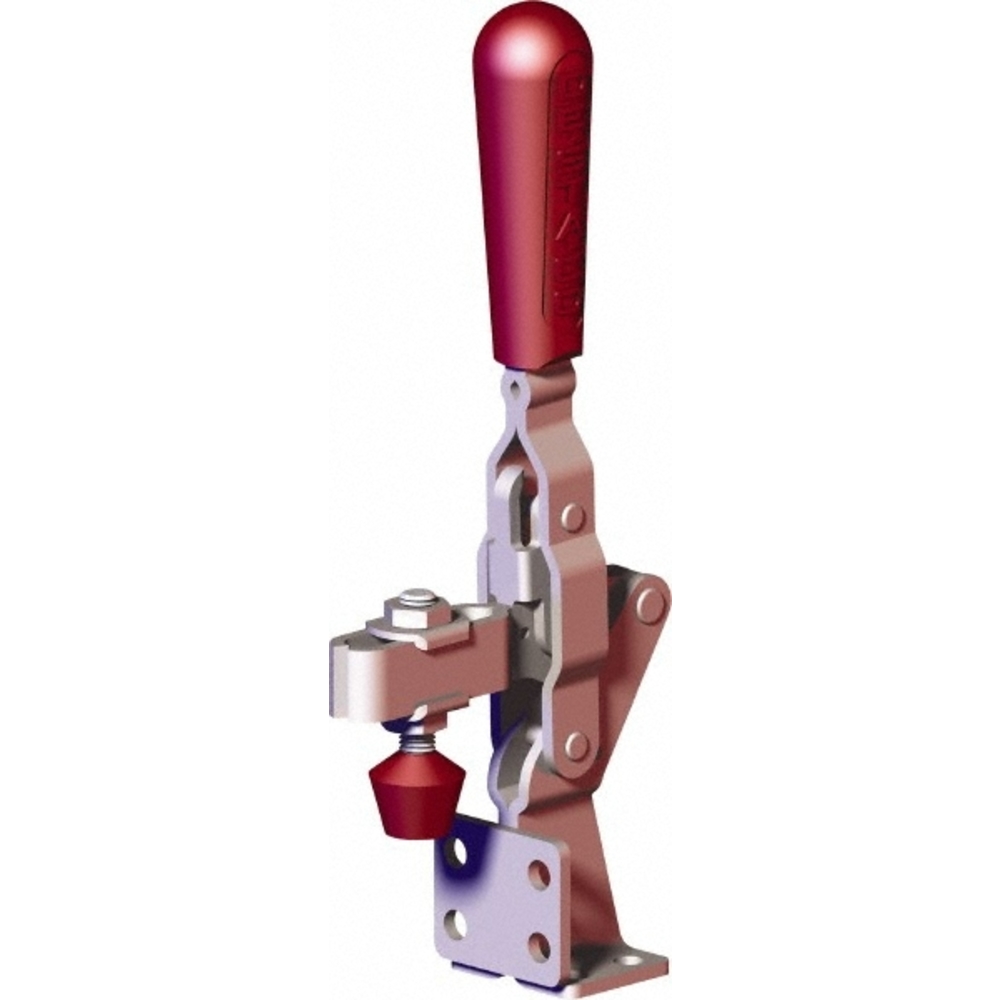

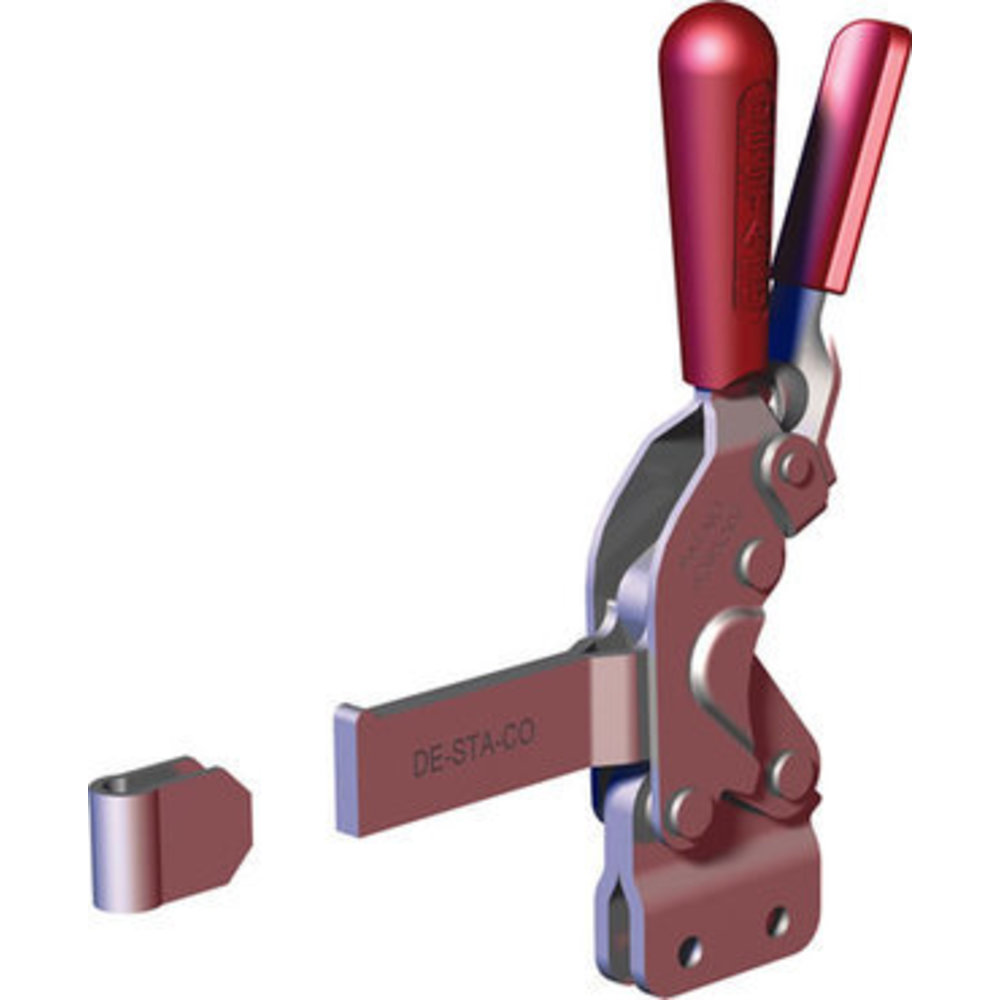

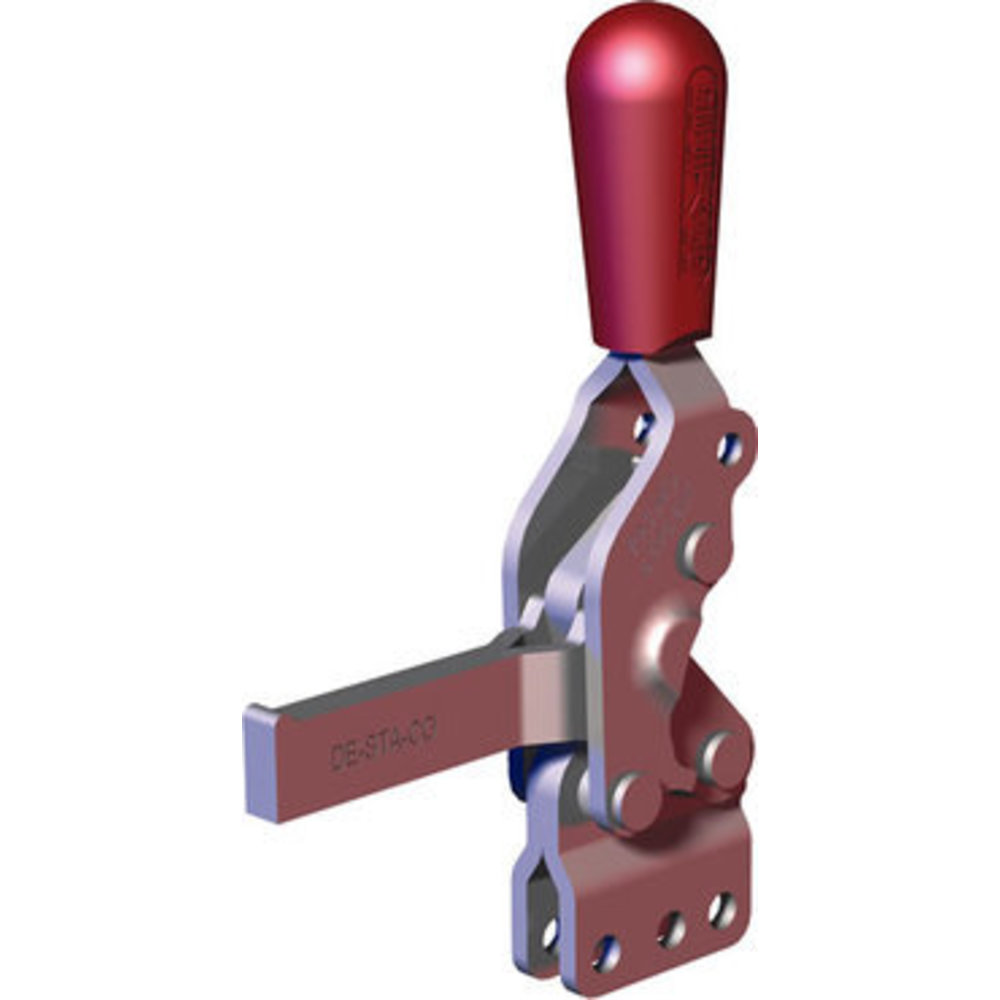

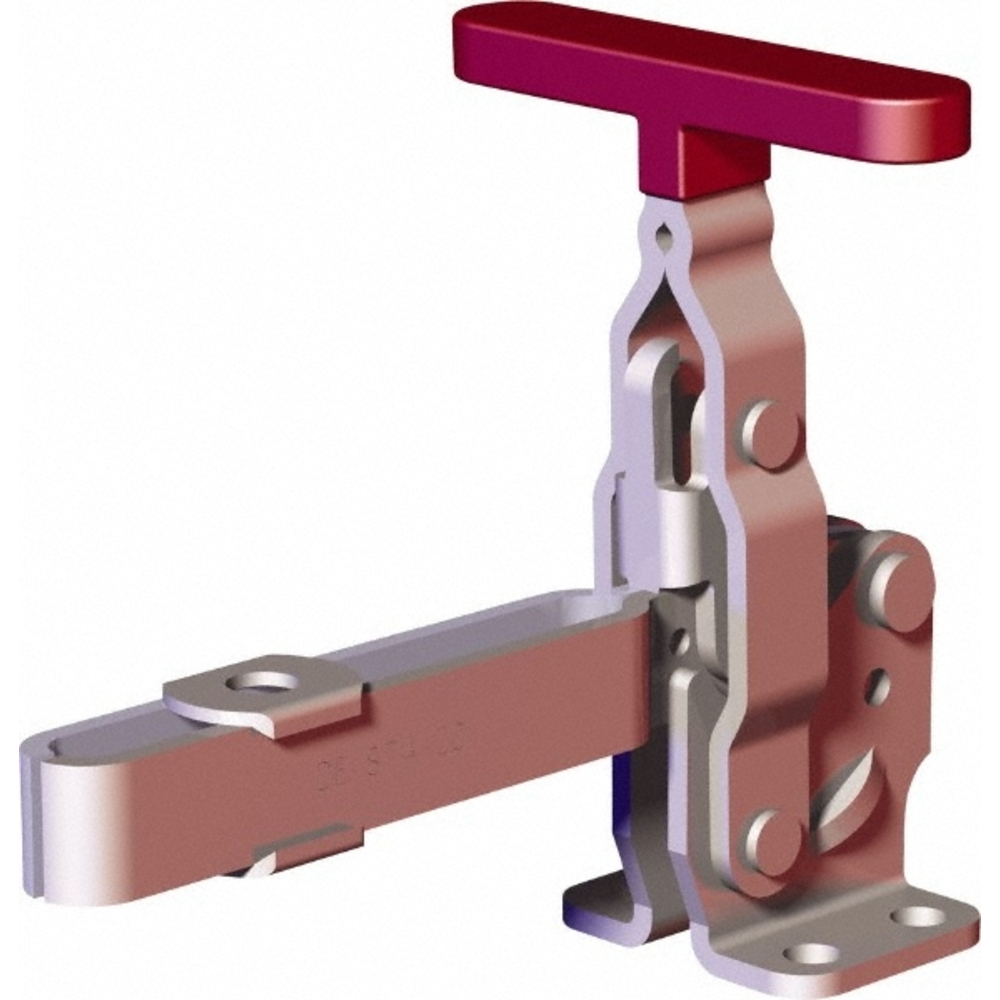

These Destaco 202 Series vertical hold down toggle clamps or heavy duty hold-down clamps are ideal for mounting to tight spaces in the . They come with lever handles that are pushed to the upright position, to hold workpieces firmly in place when the clamps are engaged. They have a fixed design for securing and loosening materials without moving the clamps. These clamps have a flanged or straight base with threaded holes for easy installation. They are suitable for checking fixtures, light machining, assembling & testing, welding, drilling, milling and woodworking applications in the automotive, aerospace, and food & packaging industries. They are used for applying downward clamping force by increasing the applied load through toggle mechanisms and are integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. These weldable vertical toggle clamps deliver flexibility to position the handle as they incorporate an ergonomic, T handle or vertical handle options with fatigue less handle grip. These vertical hold-down clamps are made of stainless steel construction for resisting corrosion on exposed surfaces and are capable of withstanding loads up to 250 lb. These clamps offer a stationary alternative to removable C clamps or spring clamps while securing material to a work surface, and have a flanged or straight base with threaded holes for quick & secure surface or blade mounting, respectively. They further come equipped with a long handle with great hand clearance that can exhibit a minimum of 90 degrees opening angle for additional safety. These clamp's bolt patterns are interchangeable with the 2002 Series toggle clamps. Further, they accommodate M6 or 1/4 inch spindle assemblies to provide maximum clamping force. These Destaco 202 Series vertical toggle clamps are available in U bar or solid bar clamp arm variants on Raptor Supplies for adjustable spindle location and customised attachments or fixed clamping, respectively.

These Destaco 202 Series vertical hold down toggle clamps or heavy duty hold-down clamps are ideal for mounting to tight spaces in the . They come with lever handles that are pushed to the upright position, to hold workpieces firmly in place when the clamps are engaged. They have a fixed design for securing and loosening materials without moving the clamps. These clamps have a flanged or straight base with threaded holes for easy installation. They are suitable for checking fixtures, light machining, assembling & testing, welding, drilling, milling and woodworking applications in the automotive, aerospace, and food & packaging industries. They are used for applying downward clamping force by increasing the applied load through toggle mechanisms and are integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. These weldable vertical toggle clamps deliver flexibility to position the handle as they incorporate an ergonomic, T handle or vertical handle options with fatigue less handle grip. These vertical hold-down clamps are made of stainless steel construction for resisting corrosion on exposed surfaces and are capable of withstanding loads up to 250 lb. These clamps offer a stationary alternative to removable C clamps or spring clamps while securing material to a work surface, and have a flanged or straight base with threaded holes for quick & secure surface or blade mounting, respectively. They further come equipped with a long handle with great hand clearance that can exhibit a minimum of 90 degrees opening angle for additional safety. These clamp's bolt patterns are interchangeable with the 2002 Series toggle clamps. Further, they accommodate M6 or 1/4 inch spindle assemblies to provide maximum clamping force. These Destaco 202 Series vertical toggle clamps are available in U bar or solid bar clamp arm variants on Raptor Supplies for adjustable spindle location and customised attachments or fixed clamping, respectively.

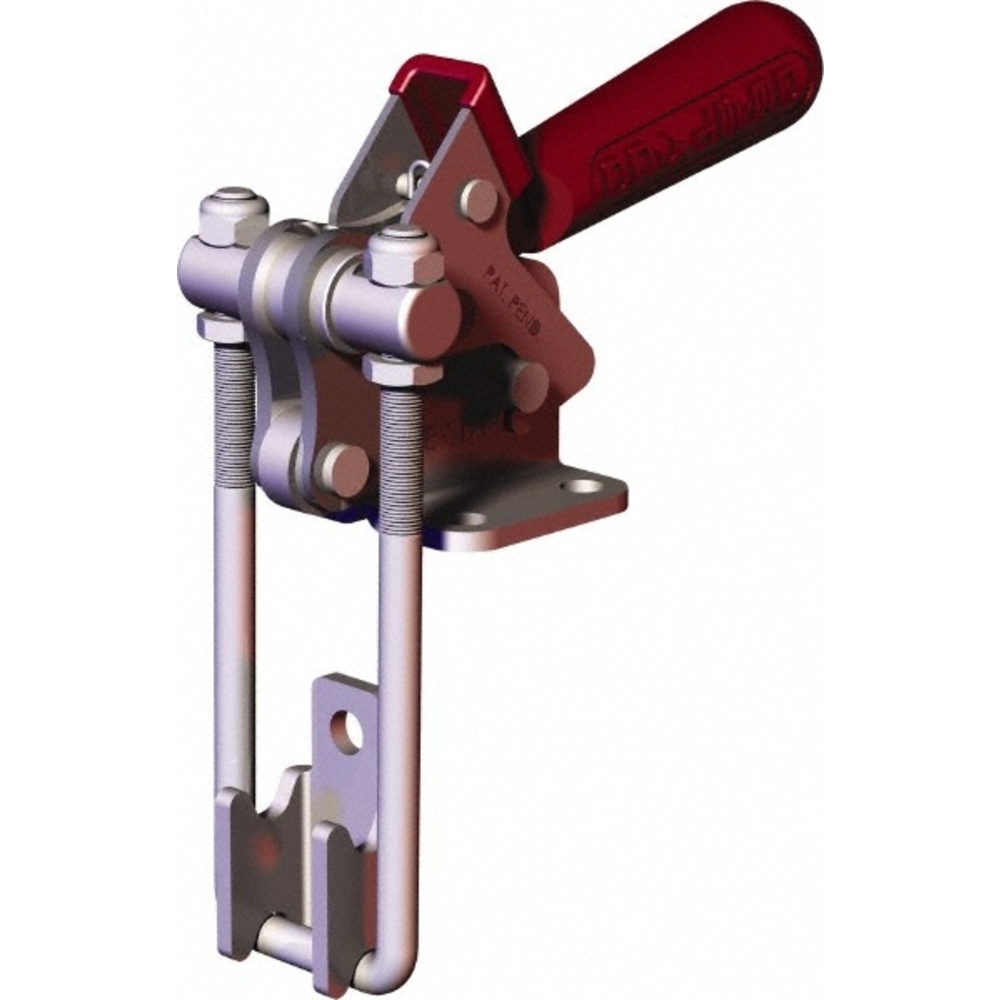

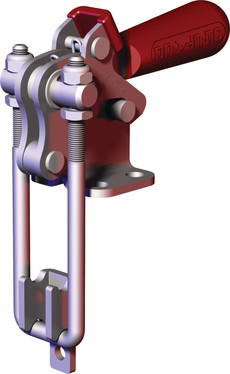

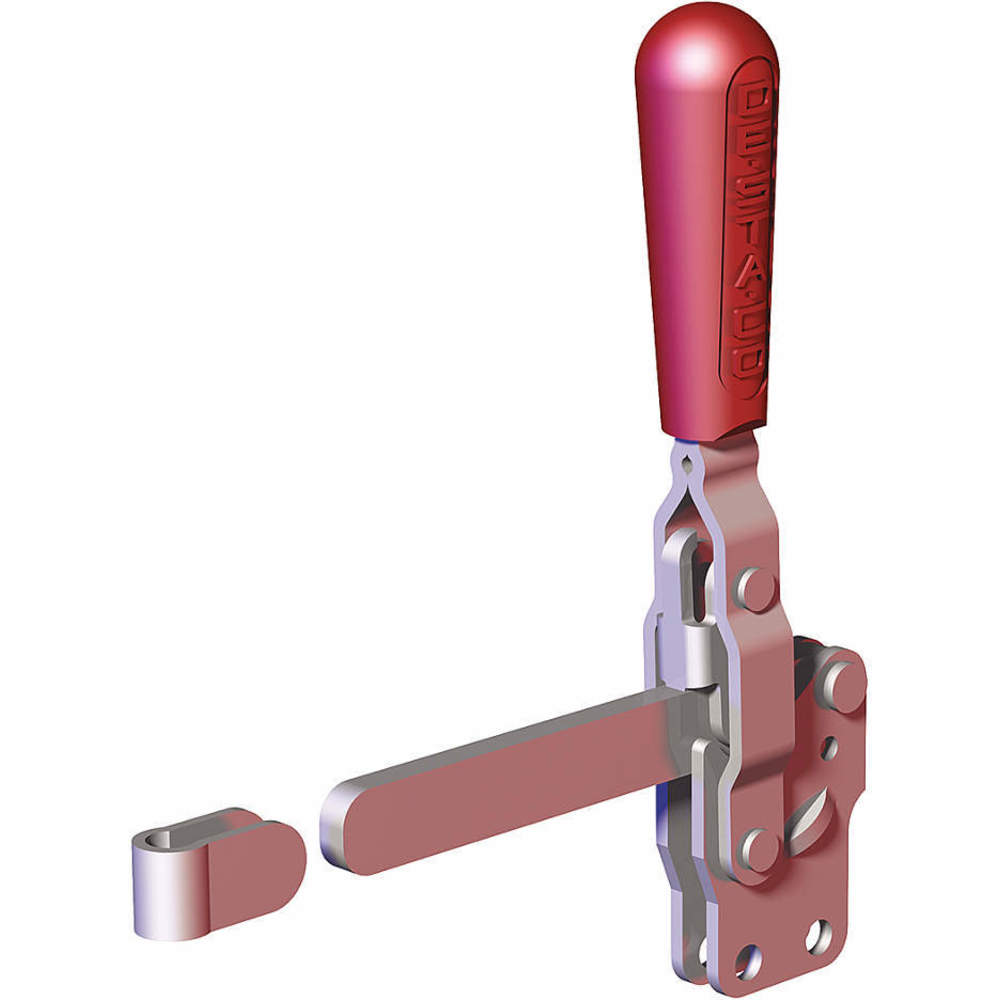

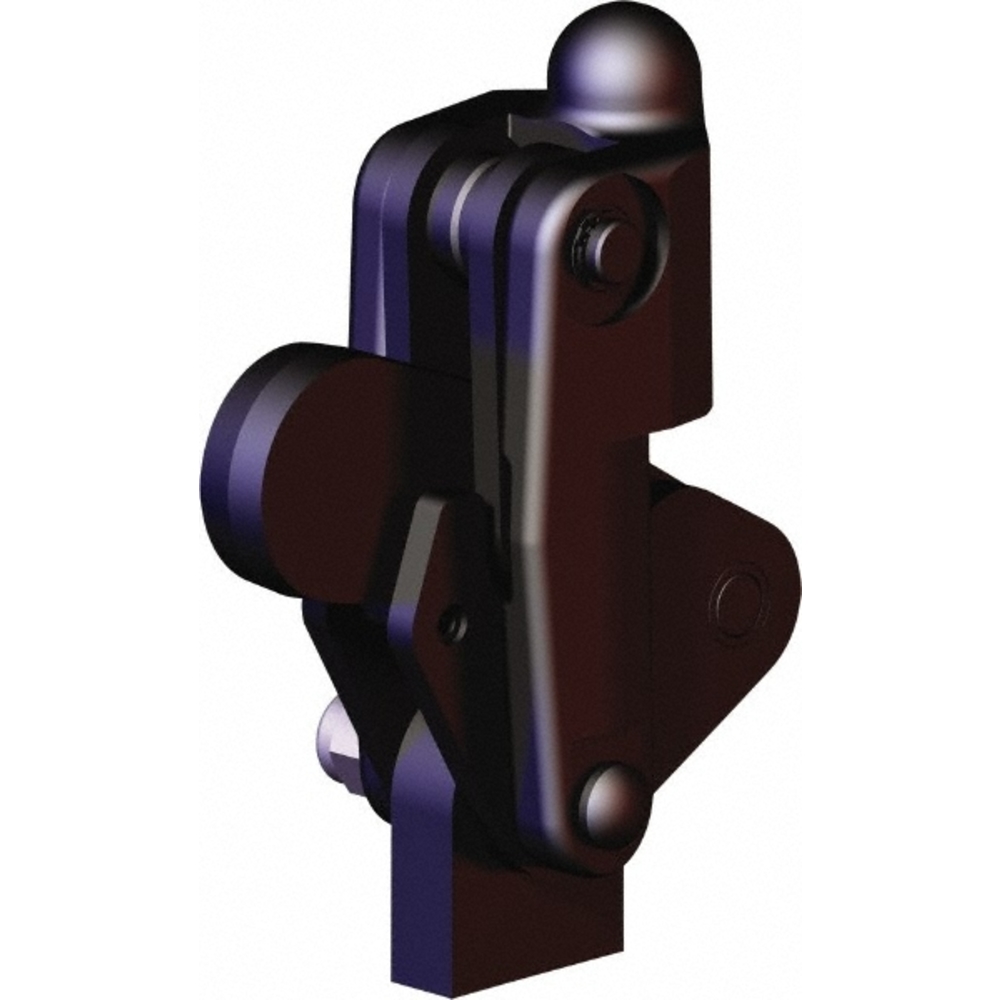

2002 Series Vertical Hold Down Clamps

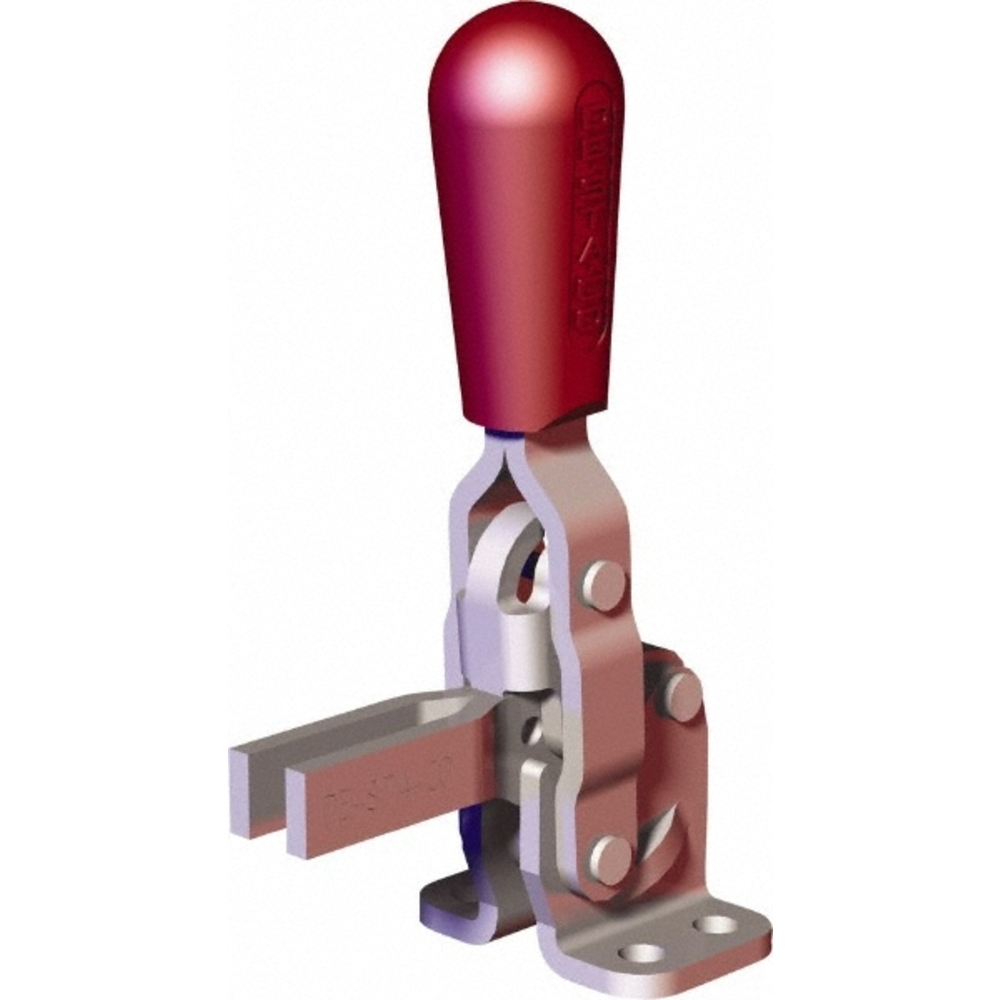

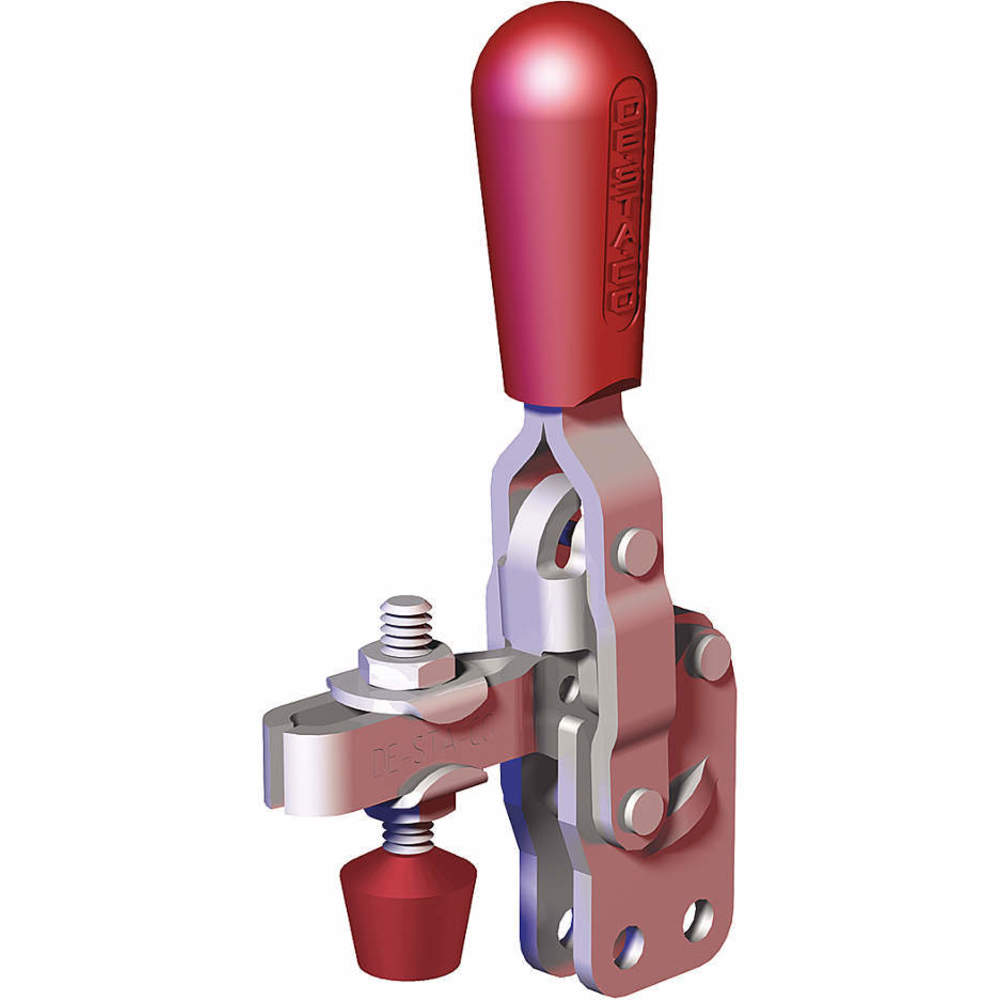

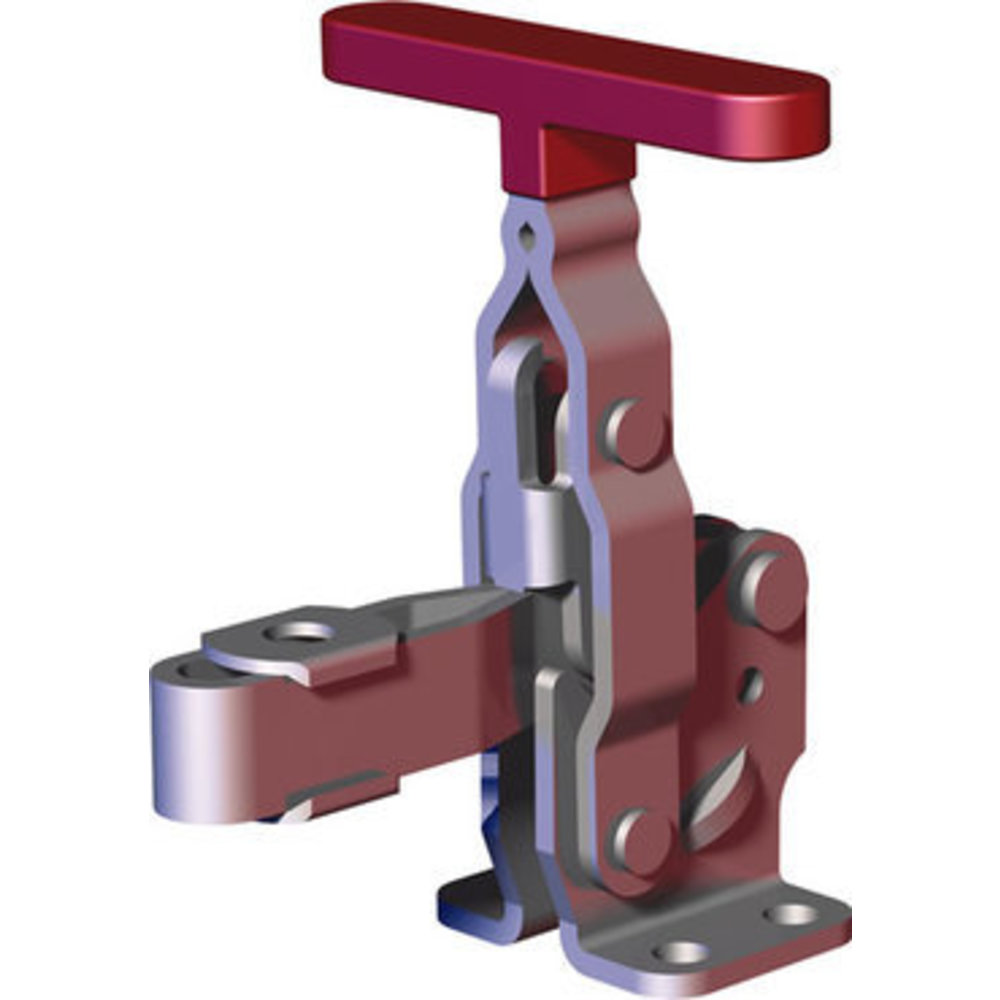

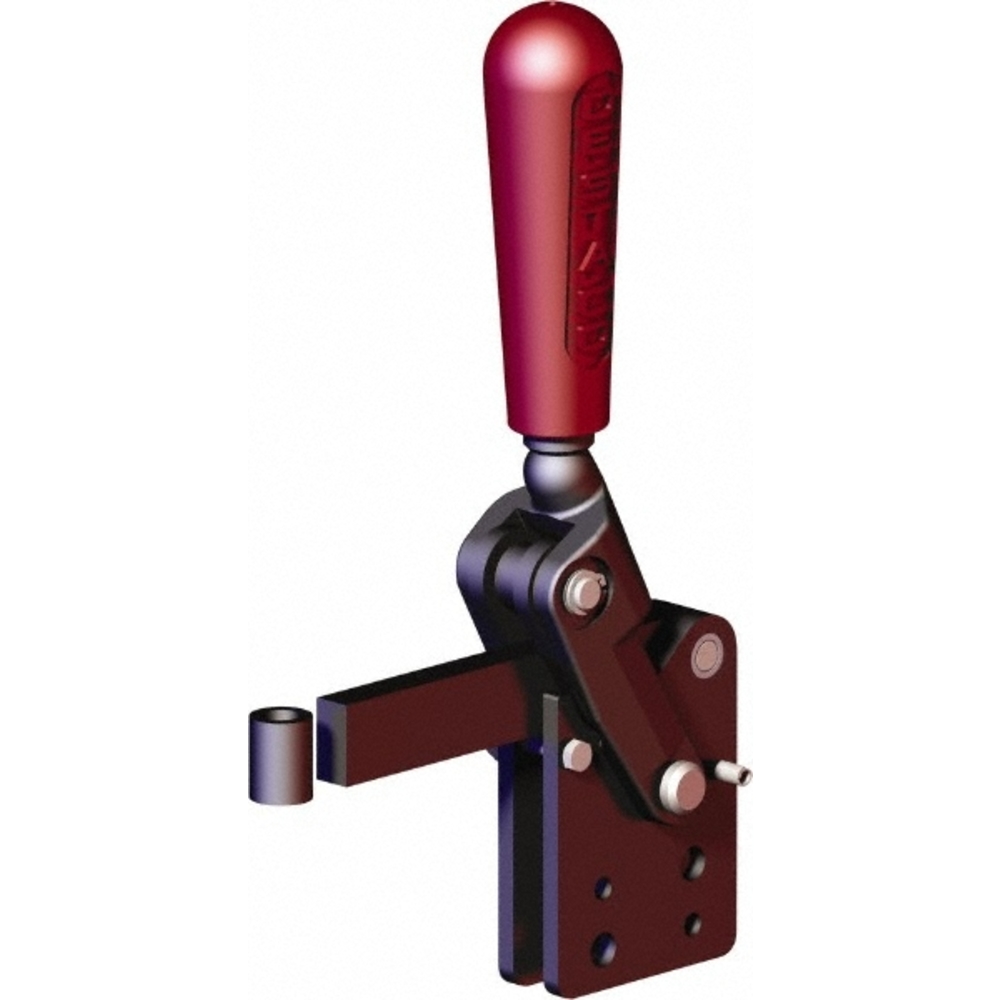

Destaco vertical hold down clamps (2002 Series) or vertical toggle clamps hold workpieces firmly in a stationary position using a lever handle that engages & releases the clamping head while pushing it to the upright position. They have a fixed design for securing and loosening materials without moving the clamps and have a flanged or straight base with threaded holes for easy installation. They are ideal for applications in the automotive, aerospace, consumer goods and food & packaging industries for checking fixtures, light machining, assembling, testing, welding, drilling, milling and woodworking. They are used for applying downward clamping force by increasing the applied load through toggle mechanisms and are integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. These weldable vertical toggle clamps provide the flexibility to position the handle, base & clamp arm and weld them in the desired position for different clamping applications. These 2002 Series Destaco clamps feature stainless steel construction with black oxide, non reflective finish (selected models) for resisting corrosion on exposed surfaces, and are capable of withstanding loads up to 600 lb. These clamps offer a stationary alternative to removable C clamps or spring clamps while securing material to a work surface and come equipped with a long handle providing excellent hand clearance that can be repositioned to limit the opening angles up to 90 degrees for additional safety. These clamp's bolt patterns are interchangeable with 202 Series toggle clamps. They are used with bolt retainers, spindle assemblies and flanged washers. Selected models come with the Toggle Lock Plus safety feature to prevent unintentional opening of the clamps. Destaco 2002 Series vertical toggle clamps are available in U bar or solid bar clamp arm variants on Raptor Supplies, for easy attachment of arm extensions.

Destaco vertical hold down clamps (2002 Series) or vertical toggle clamps hold workpieces firmly in a stationary position using a lever handle that engages & releases the clamping head while pushing it to the upright position. They have a fixed design for securing and loosening materials without moving the clamps and have a flanged or straight base with threaded holes for easy installation. They are ideal for applications in the automotive, aerospace, consumer goods and food & packaging industries for checking fixtures, light machining, assembling, testing, welding, drilling, milling and woodworking. They are used for applying downward clamping force by increasing the applied load through toggle mechanisms and are integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. These weldable vertical toggle clamps provide the flexibility to position the handle, base & clamp arm and weld them in the desired position for different clamping applications. These 2002 Series Destaco clamps feature stainless steel construction with black oxide, non reflective finish (selected models) for resisting corrosion on exposed surfaces, and are capable of withstanding loads up to 600 lb. These clamps offer a stationary alternative to removable C clamps or spring clamps while securing material to a work surface and come equipped with a long handle providing excellent hand clearance that can be repositioned to limit the opening angles up to 90 degrees for additional safety. These clamp's bolt patterns are interchangeable with 202 Series toggle clamps. They are used with bolt retainers, spindle assemblies and flanged washers. Selected models come with the Toggle Lock Plus safety feature to prevent unintentional opening of the clamps. Destaco 2002 Series vertical toggle clamps are available in U bar or solid bar clamp arm variants on Raptor Supplies, for easy attachment of arm extensions.

| Style | Model | Clamp Bar Opening | Base Length | Handle Style | Handle Opening | Bar Width (in.) | Base Width | Base Style | Bar Style | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 2002-S207 | €61.97 | |||||||||

| B | 2002-SR207 | €96.42 |

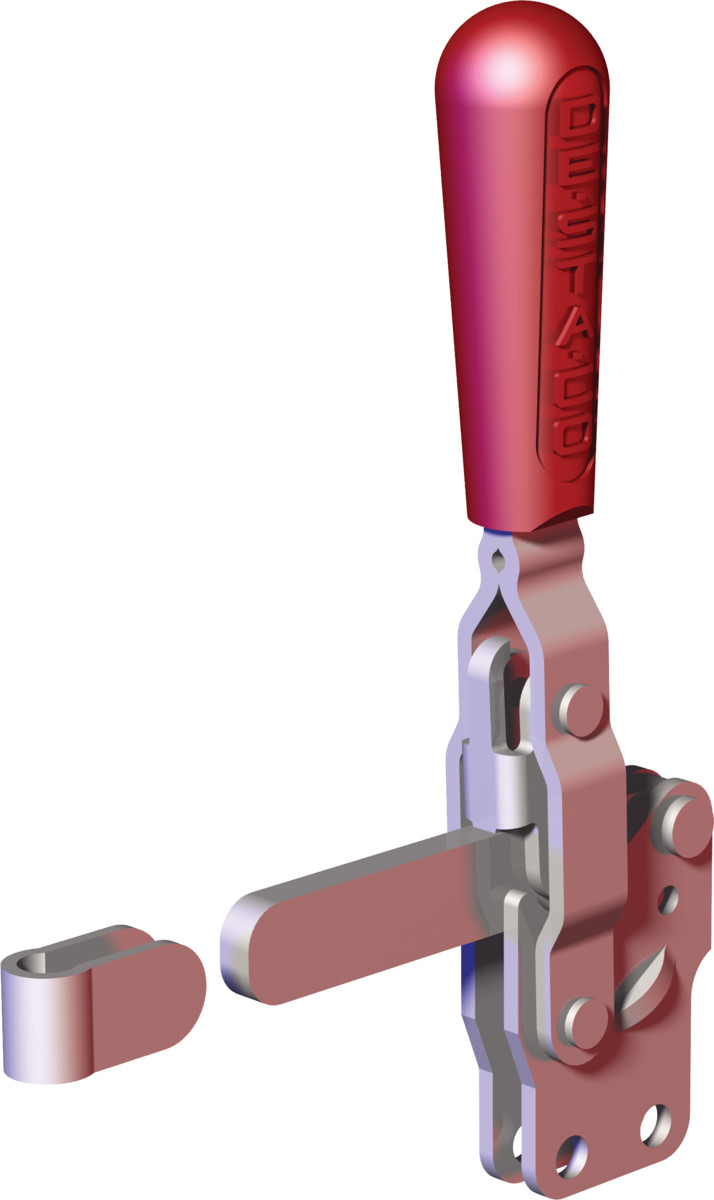

207 Series Vertical Hold Down Clamps

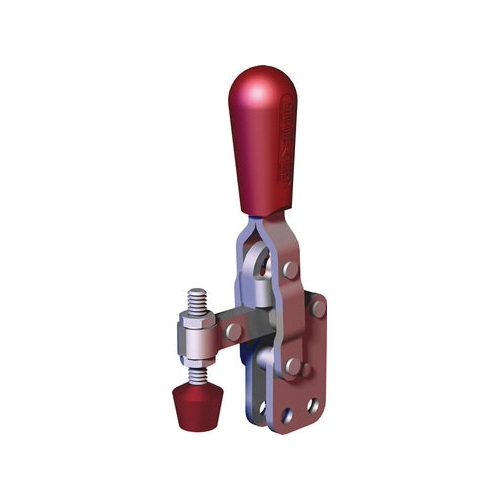

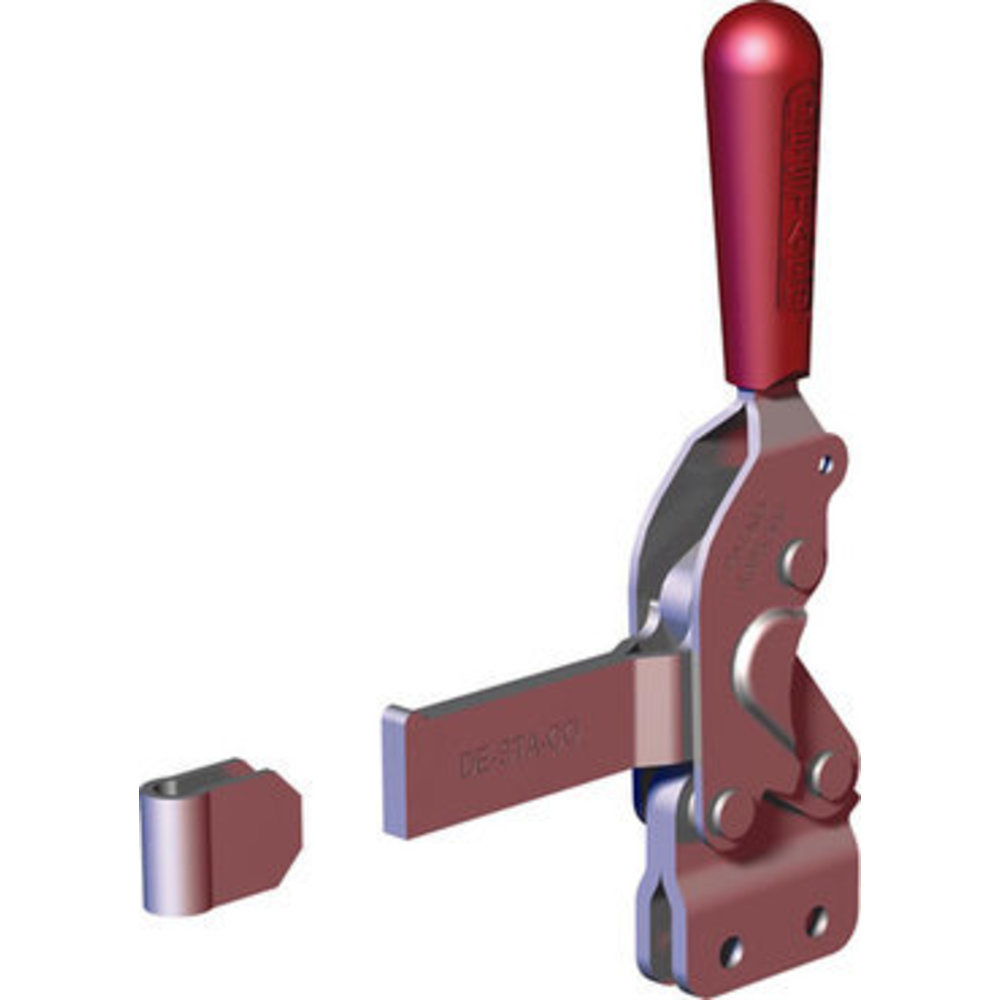

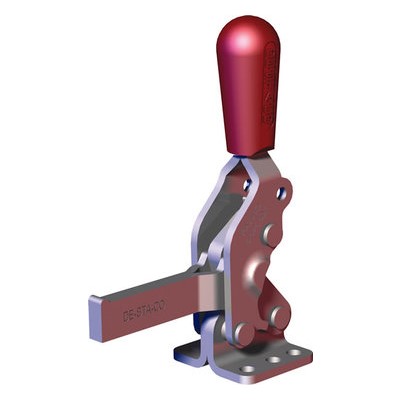

Destaco 207 Series vertical hold down clamps are designed to offer a stationary alternative to removable C clamps or spring clamps when securing materials to a work surface. These clamps mount to work surfaces and hold workpieces in place using a lever handle that is pushed to the upright position when the clamp is engaged. The lever handle engages & releases the clamping head, which holds a workpiece onto a worktable. These clamps orient the handle vertically for a 90-degree opening angle. They include various BLK model clamps with black and non-reflective finish, and different low profile T handle clamps (models including - "T") used for various arm and mounting applications. Destaco 207 Series vertical hold down toggle clamps comprise accurately machined components having hardened and ground pivot pins and bushings. These clamps enable the user to undertake an action without being worried by the frequent movement of a piece of wood. The unique pivot and unique lever system ensures maximum function and excellent performance. They have high exerting force and flexible adjustability that are useful when working with various material thicknesses. They feature a fixed design to secure & loosen workpieces without moving the clamp itself. Destaco toggle clamps are equipped with a high strength, forged alloy steel clamping arm for increased strength and handling a maximum load of 375 lb. Selected models come integrated with the Toggle Lock Plus safety feature to ensure that the over-centre locking condition is maintained and the clamp remains protected against unintentional opening.

Destaco 207 Series vertical hold down clamps are designed to offer a stationary alternative to removable C clamps or spring clamps when securing materials to a work surface. These clamps mount to work surfaces and hold workpieces in place using a lever handle that is pushed to the upright position when the clamp is engaged. The lever handle engages & releases the clamping head, which holds a workpiece onto a worktable. These clamps orient the handle vertically for a 90-degree opening angle. They include various BLK model clamps with black and non-reflective finish, and different low profile T handle clamps (models including - "T") used for various arm and mounting applications. Destaco 207 Series vertical hold down toggle clamps comprise accurately machined components having hardened and ground pivot pins and bushings. These clamps enable the user to undertake an action without being worried by the frequent movement of a piece of wood. The unique pivot and unique lever system ensures maximum function and excellent performance. They have high exerting force and flexible adjustability that are useful when working with various material thicknesses. They feature a fixed design to secure & loosen workpieces without moving the clamp itself. Destaco toggle clamps are equipped with a high strength, forged alloy steel clamping arm for increased strength and handling a maximum load of 375 lb. Selected models come integrated with the Toggle Lock Plus safety feature to ensure that the over-centre locking condition is maintained and the clamp remains protected against unintentional opening.

385 Series Pull Action Latch Clamps

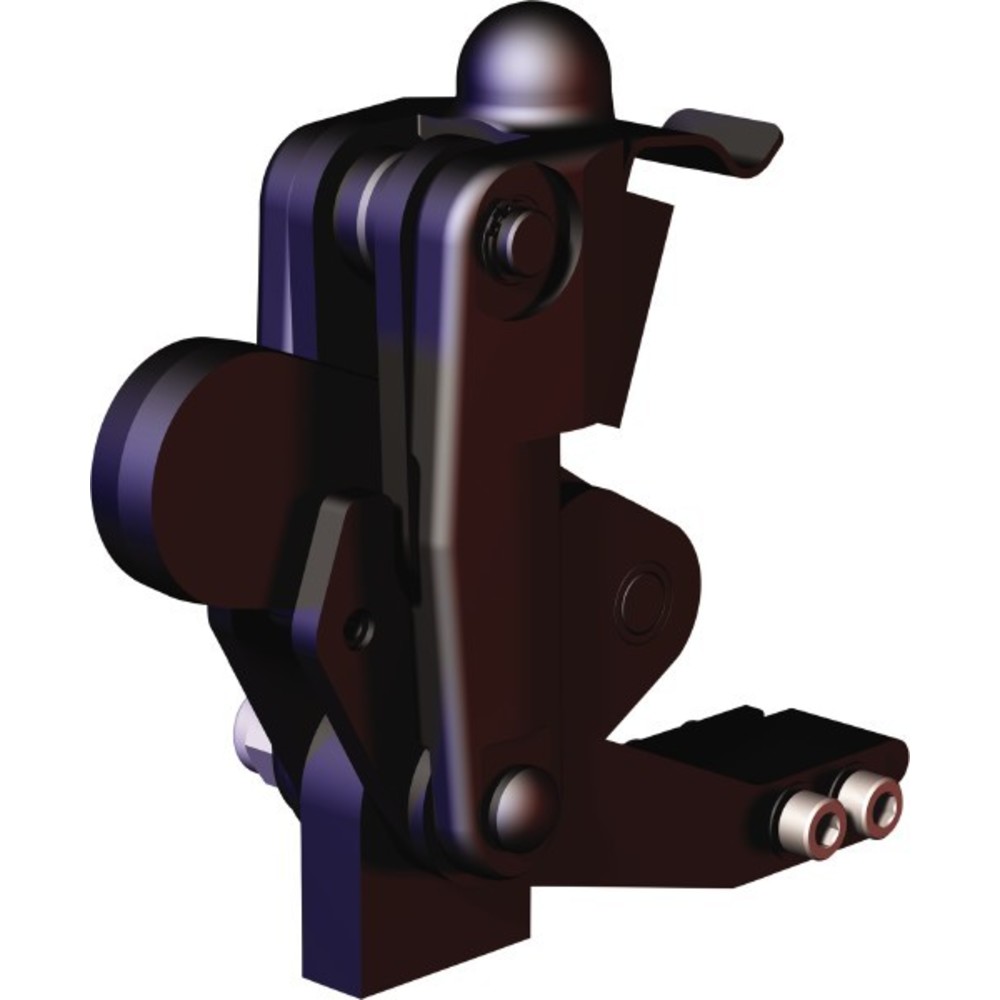

210 Series Vertical Hold Down Clamps

Destaco 210 Series vertical hold down clamps are suitable for mounting to tight spaces. They are equipped with lever handles that are pushed to the upright position for holding workpieces firmly in place when the clamps are engaged. These toggle clamps feature a fixed design for securing & loosening materials without moving the clamps, and are ideal for the automotive, aerospace, and food & packaging industries. They feature an air actuated cylinder with input port for connecting to the compressed air source and then utilise the compressed air for applying clamping pressure to hold the workpiece in place. These vertical hold down toggle clamps come integrated with hardened bushings & pins at all pivot points for longer service life. These units allow economical use on short run jobs with short term fixturing, are completely self contained & need only a single pressure source for added safety. They feature an enclosed design for MIG & spot welding in dirty working environments, and come with a non pivoting cylinder that can easily be hard piped into fixtures. Destaco vertical hold down toggle clamps are virtually maintenance free and they only require a few drops of lubricating oil to keep them in excellent condition. These clamps enable the user to undertake an action without being worried by the frequent movement of a workpiece. The unique pivot and lever system are to ensure maximum function and excellent performance. They have high exerting force and flexible adjustability that are useful when working with materials of varying thicknesses. These units are made of steel / stainless steel for resisting corrosion on exposed surfaces and come integrated with an ergonomic vertical handle for a strong & comfortable grip. These Destaco 210 Series vertical hold down toggle clamps are capable of withstanding loads up to 450 lb and have a bar opening angle of 103 degrees.

We also offer 201 Series vertical clampshaving clamp bar opening angle up to 100 degrees.

Destaco 210 Series vertical hold down clamps are suitable for mounting to tight spaces. They are equipped with lever handles that are pushed to the upright position for holding workpieces firmly in place when the clamps are engaged. These toggle clamps feature a fixed design for securing & loosening materials without moving the clamps, and are ideal for the automotive, aerospace, and food & packaging industries. They feature an air actuated cylinder with input port for connecting to the compressed air source and then utilise the compressed air for applying clamping pressure to hold the workpiece in place. These vertical hold down toggle clamps come integrated with hardened bushings & pins at all pivot points for longer service life. These units allow economical use on short run jobs with short term fixturing, are completely self contained & need only a single pressure source for added safety. They feature an enclosed design for MIG & spot welding in dirty working environments, and come with a non pivoting cylinder that can easily be hard piped into fixtures. Destaco vertical hold down toggle clamps are virtually maintenance free and they only require a few drops of lubricating oil to keep them in excellent condition. These clamps enable the user to undertake an action without being worried by the frequent movement of a workpiece. The unique pivot and lever system are to ensure maximum function and excellent performance. They have high exerting force and flexible adjustability that are useful when working with materials of varying thicknesses. These units are made of steel / stainless steel for resisting corrosion on exposed surfaces and come integrated with an ergonomic vertical handle for a strong & comfortable grip. These Destaco 210 Series vertical hold down toggle clamps are capable of withstanding loads up to 450 lb and have a bar opening angle of 103 degrees.

We also offer 201 Series vertical clampshaving clamp bar opening angle up to 100 degrees.

Latch Clamp Stainless Steel Horizontal

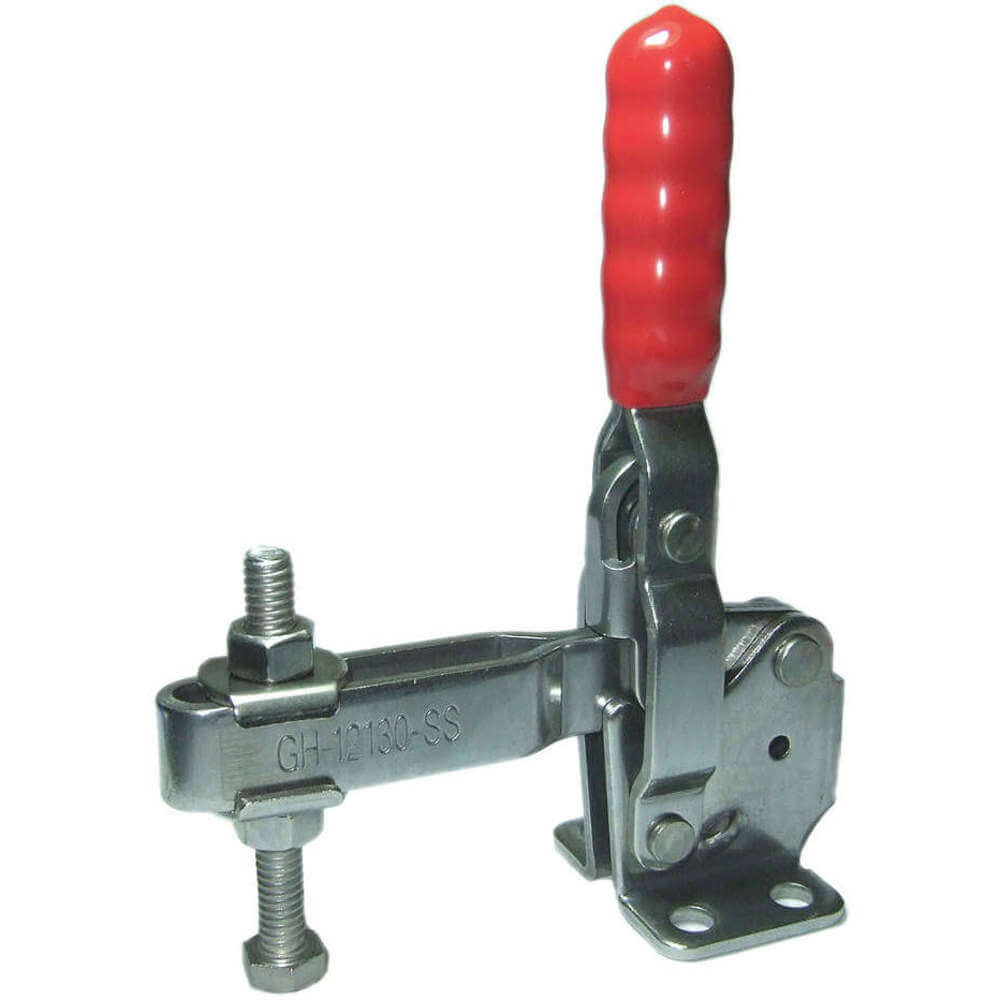

Toggle Clamp Vertical

Toggle Clamp Vertical Hold, Stainless Steel

Toggle Clamp, Horizontal

Toggle Clamp, Straight Line

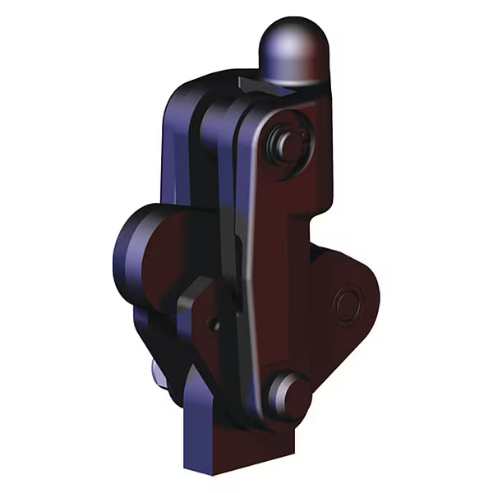

317 Series Vertical Hold Down Clamps

Destaco 317 Series vertical hold-down clamps have ergonomic handles and a U-shaped hold down bar with a large bar opening angle. These vertical clamps have a dual mounting surface and are supplied with M8 or 5/16-inch spindle accessories.

Destaco 317 Series vertical hold-down clamps have ergonomic handles and a U-shaped hold down bar with a large bar opening angle. These vertical clamps have a dual mounting surface and are supplied with M8 or 5/16-inch spindle accessories.

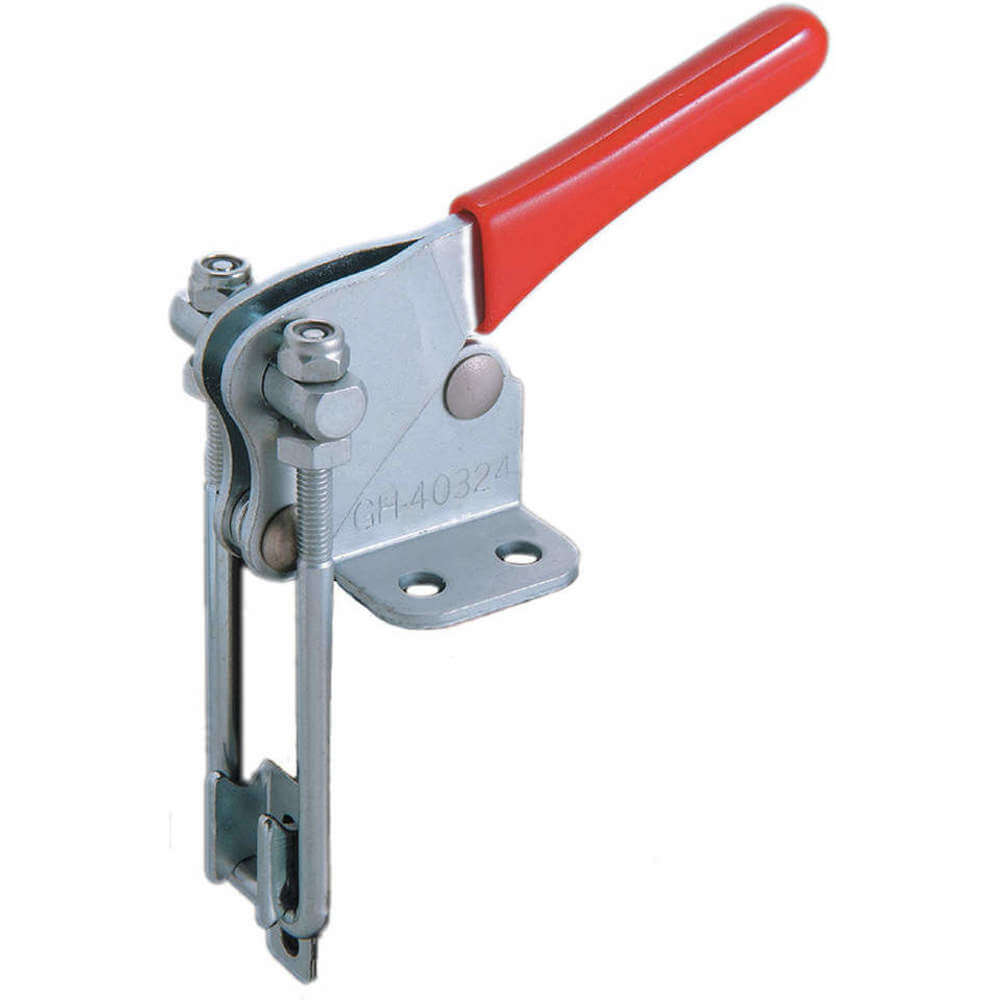

353 Series Pull Action Latch Clamps

Destaco 353 Series pull action latch clamp has a carbon steel or stainless-steel body construction with replaceable stainless-steel pivot pins for easy maintenance and an ergonomic handle. This latch clamps are ideal for clamping directly on the parting lines of a mould. Destaco pull action clamp is suitable for applications in moulding, closures manufacturing and welding applications

Destaco 353 Series pull action latch clamp has a carbon steel or stainless-steel body construction with replaceable stainless-steel pivot pins for easy maintenance and an ergonomic handle. This latch clamps are ideal for clamping directly on the parting lines of a mould. Destaco pull action clamp is suitable for applications in moulding, closures manufacturing and welding applications

Hold Down Toggle Clamps

| Style | Model | Base Mounting Style | Includes Locking Handle | Handle Orientation | Maximum Holding Capacity | Arm Style | Clamp Arm Opening Angle | Clamp Bar Opening | Clamp Arm Style | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 210-SB | €36.46 | |||||||||

| B | 307-URSS | €107.52 | |||||||||

| C | 225-URSS | €98.12 | |||||||||

| D | 2002-URSS | €87.50 | |||||||||

| E | 2007-URSS | €110.27 | |||||||||

| F | 2002-USS | €56.55 | |||||||||

| G | 2007-USS | €71.98 | |||||||||

| H | 207-L | €25.15 | |||||||||

| B | 305-URSS | €59.82 |

202 Series Vertical Hold Down Clamps, Stainless Steel

334 Series Pull Action Latch Clamps

| Style | Model | Type | Diameter | Base Mounting Centers | Hook Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|

| A | 334-SS-M-50 | €100.60 | |||||

| B | 334 | €46.00 | |||||

| C | 334-SS | €80.88 |

324-R Series Pull Action Latch Clamps

| Style | Model | Base Length | Handle Style | Bar Width (in.) | Hook Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|

| A | 324-R-M-100 | €134.99 | |||||

| A | 324-R-M-50 | €67.46 | |||||

| A | 324-R-M-25 | €134.99 | |||||

| B | 324-R | €57.26 |

344 Series Pull Action Latch Clamps

| Style | Model | Type | Diameter | Base Mounting Centers | Hook Type | Clamp Arm Style | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | 344-SS-M-50 | €188.29 | ||||||

| B | 344 | €73.13 | ||||||

| C | 344-SS | €154.73 |

207 Series Vertical Hold Down Clamps, Flanged Base, U Bar

| Style | Model | Clamp Arm Style | Clamp Bar Opening | Type | Handle | Handle Opening | Diameter | Base Mounting Centers | Spindle | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 207-UL | €36.16 | |||||||||

| B | 207-U-L-BLK | €39.38 | |||||||||

| A | 207-U | €31.32 | |||||||||

| C | 207-USS | €80.38 | |||||||||

| D | 207-UR | €73.09 |

5105, 5110 Series Heavy Duty Vertical Hold Down Clamps

344-R Series Pull Action Latch Clamps

| Style | Model | Base Length | Handle Style | Bar Width (in.) | Base Width | Hook Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | 344-RSS | €192.22 | ||||||

| B | 344-R-M-25 | €218.24 | ||||||

| B | 344-R-M-100 | €132.44 | ||||||

| B | 344-R-M-50 | €218.24 | ||||||

| C | 344-R | €128.65 |

334-R Series Pull Action Latch Clamps

| Style | Model | Base Length | Handle Style | Bar Width (in.) | Base Width | Hook Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | 334-RSS | €93.24 | ||||||

| B | 334-R-M-100 | €160.26 | ||||||

| B | 334-R-M-50 | €160.26 | ||||||

| B | 334-R-M-25 | €96.50 | ||||||

| B | 334-R | €82.46 |

2010 Series Vertical Hold Down Clamps, U Bar

2010 Series Vertical Hold Down Clamps, Solid Bar

2007 Series Vertical Hold Down Clamps, Solid Bar

2002 Series Vertical Hold Down Clamps, Solid Bar

207 Series Vertical Hold Down Clamps, Straight Base, Solid Bar

207 Series Vertical Hold Down Clamps, Flanged Base, T Handle

344-M Series Pull Action Latch Clamps

528 Series Heavy Duty Vertical Hold Down Clamps

374-M Series Pull Action Latch Clamps

500 Series Weldable Vertical Hold Down Clamps

| Style | Model | Base Length | Height To Top Of Clamp Arm | Spring Clip | Base Width | Clamp Bar Opening | Clamp Arm Style | Type | Handle | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 506-MLBX18 | €382.27 | RFQ | ||||||||

| A | 505-MLBX17 | €195.61 | RFQ | ||||||||

| A | 505-MLBLSCX17 | €311.76 | RFQ | ||||||||

| A | 503-MLBX1701 | €244.06 | RFQ | ||||||||

| B | 503-MB | €103.49 | |||||||||

| A | 501-MLBX1701 | €240.60 | RFQ | ||||||||

| C | 503-MLB | €99.53 | |||||||||

| D | 503-MLBLSC | €449.00 | |||||||||

| E | 503-MBLSC | €302.90 | |||||||||

| F | 501-LB | €100.68 | |||||||||

| G | 505-MBLSC | €202.88 | |||||||||

| H | 505-MB | €126.11 | |||||||||

| H | 506-MB | €175.03 | |||||||||

| I | 506-MBLSC | €462.75 | |||||||||

| J | 505-MLB | €120.49 | |||||||||

| K | 505-MLBLSC | €643.06 | |||||||||

| L | 506-MLBLSC | €339.16 | |||||||||

| M | 506-MLB | €170.26 | |||||||||

| N | 501-B | €98.70 |

2002 Series Vertical Hold Down Clamps, U-Bar

533, 535 Series Heavy Duty Vertical Hold Down Clamps

5905, 5910, 5915 Series Heavy Duty Vertical Hold Down Clamps

Vertical Handle Toggle Clamps

Vertical handle toggle clamps are used in heavy duty vertical clamping operations due to their high clamping capacities and reliability. Raptor Supplies is an authorized vertical handle toggle clamp distributor for various brands like Destaco, Clamp right, Bessey etc which are available in different bar size, base length, base width, diameter and load capacity.

Features

- They have increased handle clearance to reduce pinch points, as well as a fixed-handle pivot for smooth operation.

- These Destaco horizontal hold-down clamps are used in woodworking, fixture checking, light machining and equipment testing.

- They also have a U-shaped arm with a maximum carrying capacity of 295 lb (133.81 kg).

Bessey Auto-adjust Toggle Clamps :

- They automatically adjust to changes in workpiece height while maintaining a constant clamping force.

- These Bessey vertical toggle clamps have large handles with soft insets for comfortable operations.

- They have an adaptable base plate with precisely spaced holes for easy mounting.

Frequently Asked Questions

Are there maintenance requirements for vertical hold-down clamps?

Regular maintenance includes cleaning, lubrication of moving parts and inspection for any signs of wear or damage.

What are the key considerations when selecting a vertical hold-down toggle clamp?

Consider factors such as clamping force, handle operation and the specific requirements of your application. Ensure that the chosen clamp is suitable for vertical clamping tasks and meets the load and size specifications of your workpieces.

Can vertical toggle clamps be used for CNC machining applications?

Yes, vertical handle toggle clamps are often used in CNC machining applications to secure workpieces in a vertical orientation, ensuring stability during the machining process.

Are plunger action toggle clamps suitable for vertical clamping?

Plunger action toggle clamps are designed for applications where a straight-line action is required. While they can be used in certain vertical applications, vertical handle toggle clamps are more specifically tailored for vertical clamping tasks.

What is the purpose of a pull action latch in a vertical toggle clamp?

The pull action latch in a vertical toggle clamp secures the clamp in the closed position, ensuring a reliable and stable hold on the workpiece.

How do you release the clamping force with a vertical clamp?

Releasing the clamping force is typically achieved by lifting the vertical handle and disengaging the toggle mechanism.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- VERNON DEVICES

- VIEGA PROPRESS

- Gage Blocks/Clamps Surveillance Masters

- Lynch Pins

- Bulk Storage Lockers

- Divider Box Accessories

- Ball Pein Hammers

- DIXON Long Nuts

- IFM Springs

- WHEATON Freezer Box Green

- MARCOM Compressed Gas Cylinders

- TORNADO Screws

- CONDOR Left Hand Only Welding Glove, Stick

- ALLEGRO Tyvek Maintenance Free Hoods

- AKRO-MILS 30128 Shelf Bins