These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Motors

- Definite Purpose AC Motors

- Vacuum Motors

AMETEK LAMB Vacuum Motors

Includes a variety of UL-recognised and CSA-certified industrial vacuum motors, such as peripheral, tangential and thru-flow discharge Ametek Lamb vacuum motors, in different diameters

Includes a variety of UL-recognised and CSA-certified industrial vacuum motors, such as peripheral, tangential and thru-flow discharge Ametek Lamb vacuum motors, in different diameters

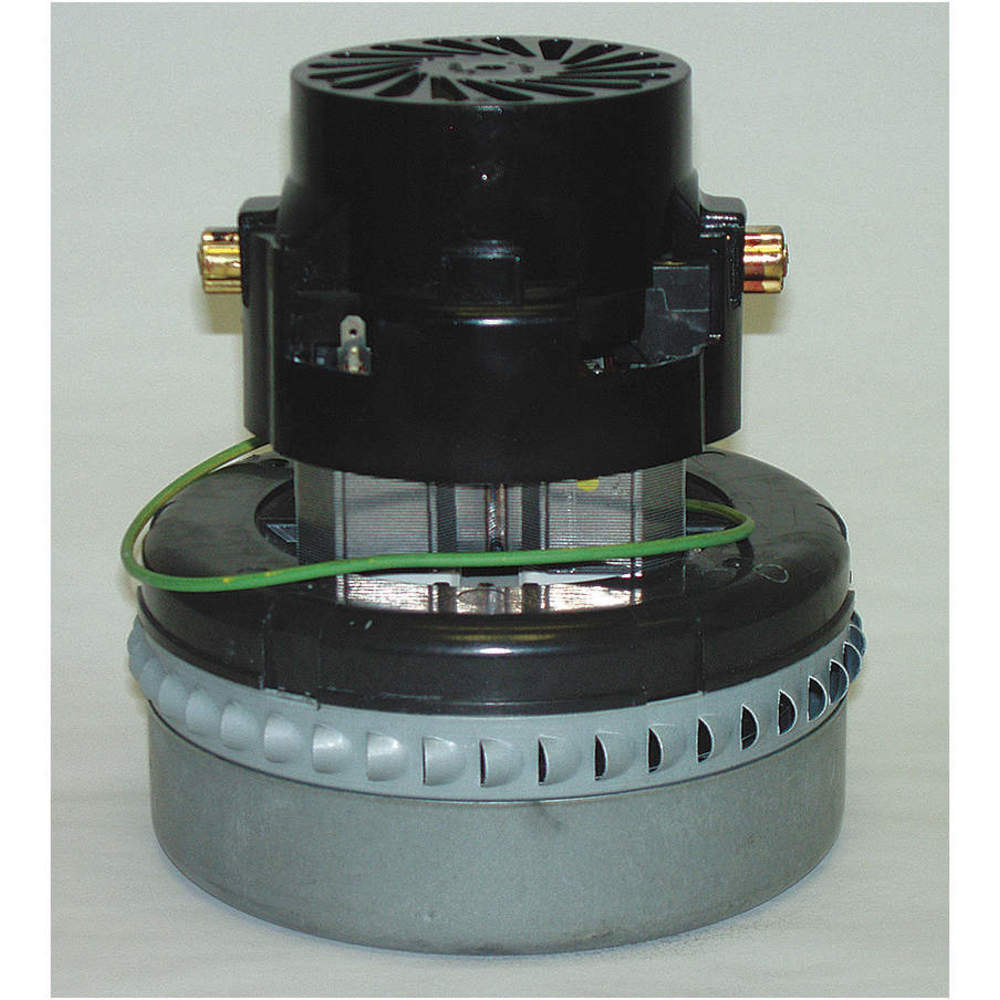

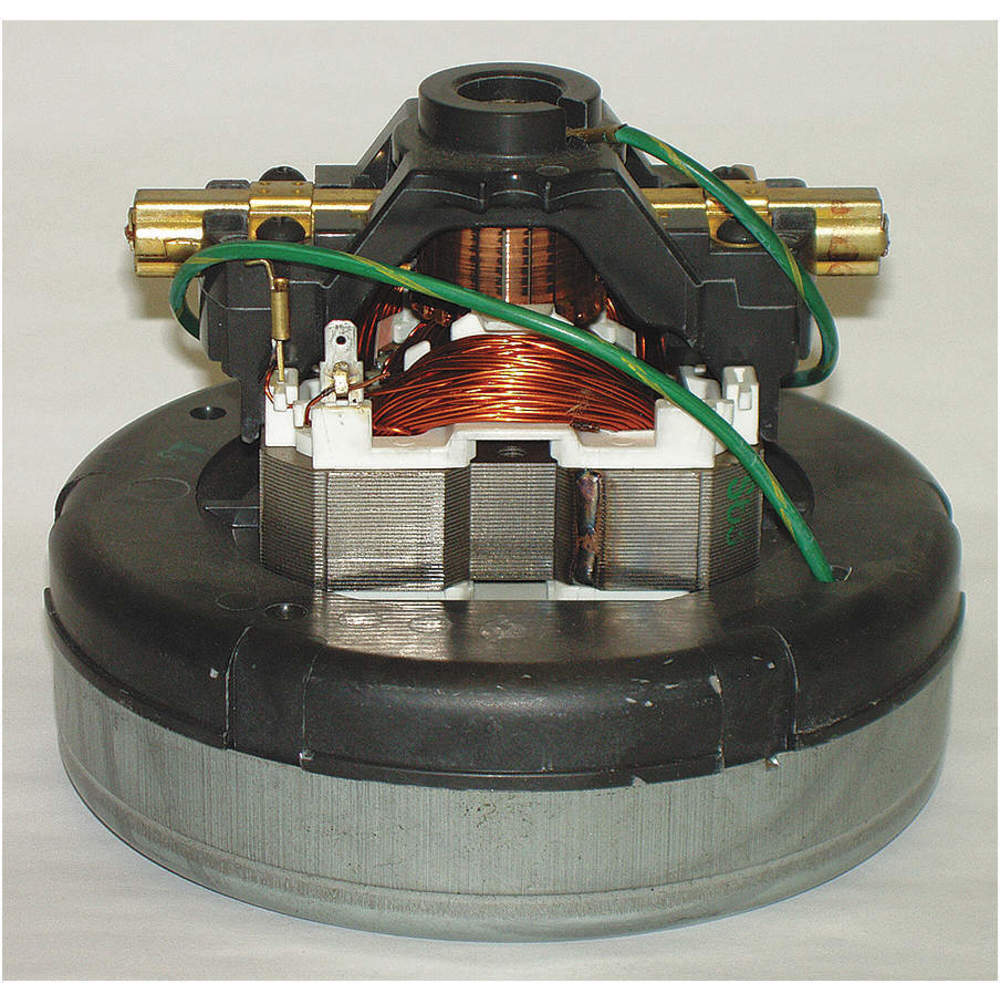

Peripheral Discharge Vacuum Motors

| Style | Model | Voltage | Body Dia. | Blower Stages | Cfm @ 2-In. Orifice | Max. Air Watts | Average Life | Insulation Class | Overall Height | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 116155-00 | €341.99 | |||||||||

| B | 116514-13 | €304.97 | |||||||||

| B | 116156-00 | €320.61 | |||||||||

| A | 119431-13 | €296.33 | |||||||||

| B | 116512-13 | €302.31 | |||||||||

| C | 115419 | €1,191.40 | |||||||||

| D | 116196-00 | €165.38 | |||||||||

| A | 116493-50 | €175.63 | |||||||||

| B | 116471-13 | €238.44 | |||||||||

| A | 116212-00 | €235.76 | |||||||||

| B | 116448-00 | €211.34 | |||||||||

| B | 115757-P | €200.28 | |||||||||

| E | 114787 | €717.94 | |||||||||

| F | 116758-13 | €198.32 | |||||||||

| G | 116325-00 | €133.09 | |||||||||

| F | 116763-13 | €259.44 | |||||||||

| H | 119413-13 | €160.32 | |||||||||

| A | 116566-13 | €307.47 | |||||||||

| I | 115330 | €381.62 | |||||||||

| J | 115962 | €372.38 | |||||||||

| K | 116024-13 | €177.90 | |||||||||

| F | 116757-13 | €166.17 | |||||||||

| L | 117508-00 | €347.07 | |||||||||

| B | 116336-01 | €162.89 | |||||||||

| M | 119414-00 | €139.46 |

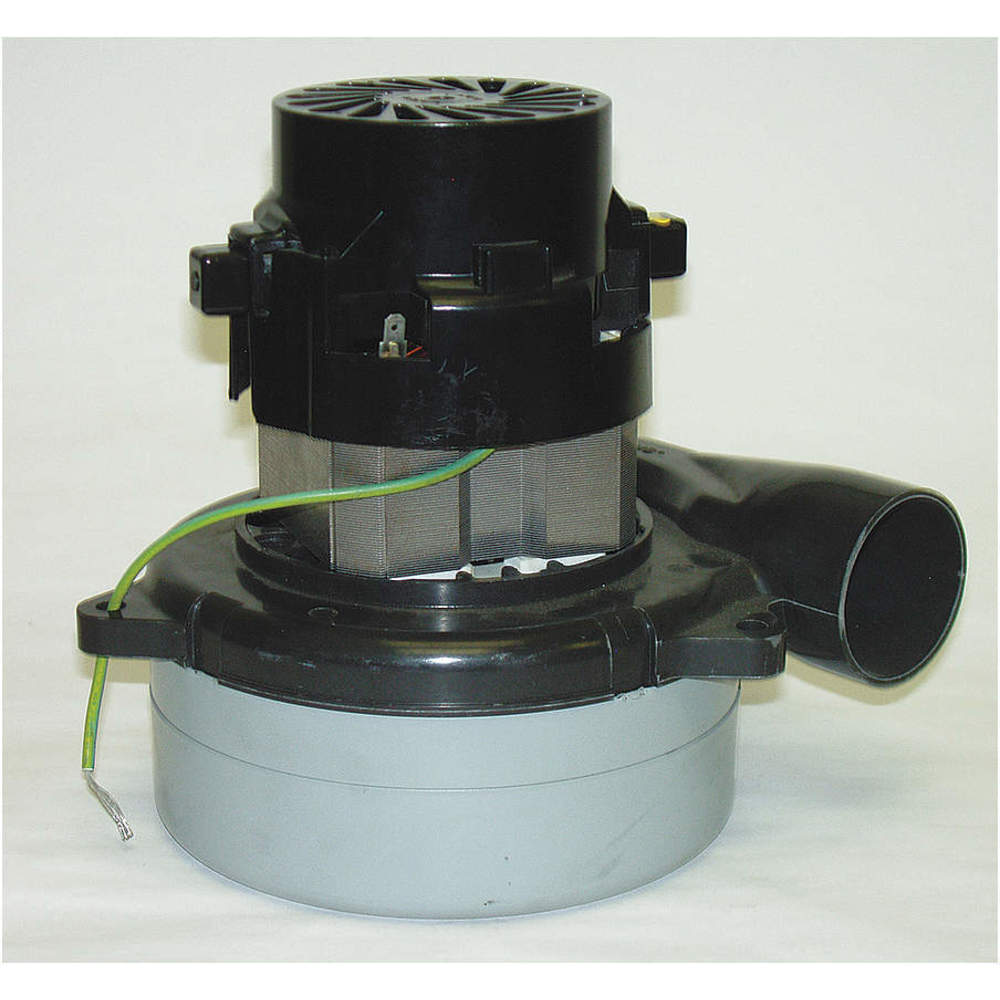

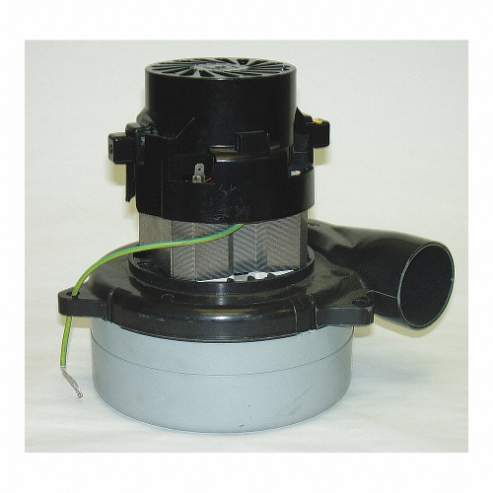

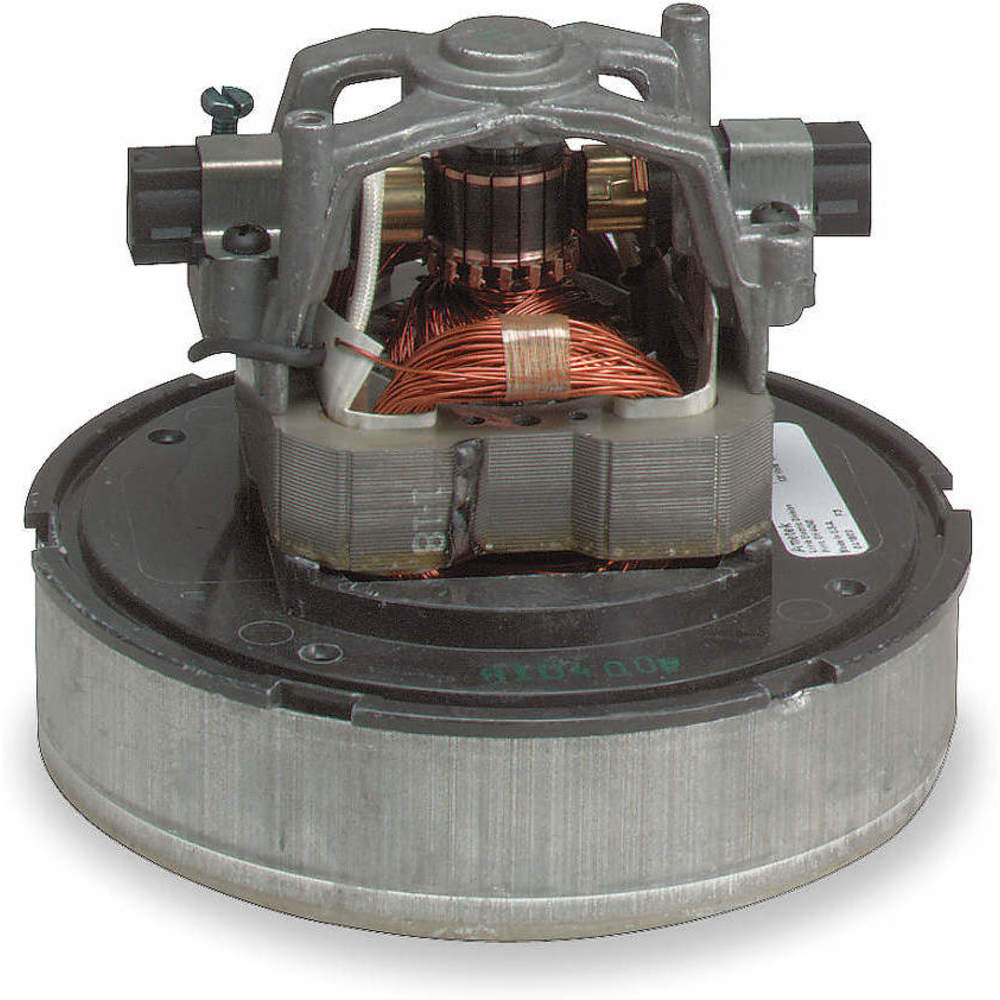

Tangential Discharge Vacuum Motors

Ametek Lamb tangential discharge, open drip-proof vacuum motors are specially designed to move clean and dry air in commercial vacuums, dental evacuators and material handling & transfer systems. The brand's heavy-duty motors feature fan brackets to provide directional vanes to move the air through the fan system more efficiently and air seal bearings to prevent vacuum loss. These energy-efficient vacuum motors come in 2- and 3-stage configurations used to create either more pressure or lift when used as a blower or vacuum, respectively. Single-stage motors typically have the highest air flow and are suitable for a range of appliances including central vacuums, carpet extractors and mould injection motors. Ametek noiseless tangential discharge vacuum motors have an average life of 1500 hrs & brush life up to 1000 running hours and can be mounted in all positions. Raptor Supplies offers a wide variety of Ametek Lamb tangential discharge vacuum motors, available for operation at 24 & 36 VDC and 120 and 240 VAC.

Ametek Lamb tangential discharge, open drip-proof vacuum motors are specially designed to move clean and dry air in commercial vacuums, dental evacuators and material handling & transfer systems. The brand's heavy-duty motors feature fan brackets to provide directional vanes to move the air through the fan system more efficiently and air seal bearings to prevent vacuum loss. These energy-efficient vacuum motors come in 2- and 3-stage configurations used to create either more pressure or lift when used as a blower or vacuum, respectively. Single-stage motors typically have the highest air flow and are suitable for a range of appliances including central vacuums, carpet extractors and mould injection motors. Ametek noiseless tangential discharge vacuum motors have an average life of 1500 hrs & brush life up to 1000 running hours and can be mounted in all positions. Raptor Supplies offers a wide variety of Ametek Lamb tangential discharge vacuum motors, available for operation at 24 & 36 VDC and 120 and 240 VAC.

| Style | Model | Voltage | Motor Enclosure Design | Discharge | Body Dia. | Blower Stages | Cfm @ 2-In. Orifice | Thermal Protection | Motor/blower Type | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 119433-13 | €265.71 | |||||||||

| B | 122173-18 | €433.07 | |||||||||

| C | 119436-13 | €260.05 | |||||||||

| A | 116515-13 | €314.97 | |||||||||

| A | 116157-00 | €326.49 | |||||||||

| A | 116513-13 | €279.36 | |||||||||

| D | 116409-13 | €288.91 | |||||||||

| D | 119432-13 | €267.30 | |||||||||

| D | 116513-32 | €317.26 | |||||||||

| E | 122175-00 | €304.13 | |||||||||

| E | 122176-18 | €305.27 | |||||||||

| F | 117500-12 | €365.92 | |||||||||

| F | 116161-00 | €430.94 | |||||||||

| G | 116671-50 | €189.48 | |||||||||

| A | 115894 | €218.39 | |||||||||

| H | 116765-13 | €273.03 | |||||||||

| A | 116565-13 | €270.17 | |||||||||

| D | 116210-85 | €215.45 | |||||||||

| A | 116472-13 | €213.91 | |||||||||

| I | 122133-00 | €304.57 | |||||||||

| I | 122170-18 | €319.28 | |||||||||

| J | 117507-13 | €458.12 | |||||||||

| K | 119412-13 | €177.91 | |||||||||

| L | 117488-13 | €462.08 | |||||||||

| F | 116103-00 | €420.54 |

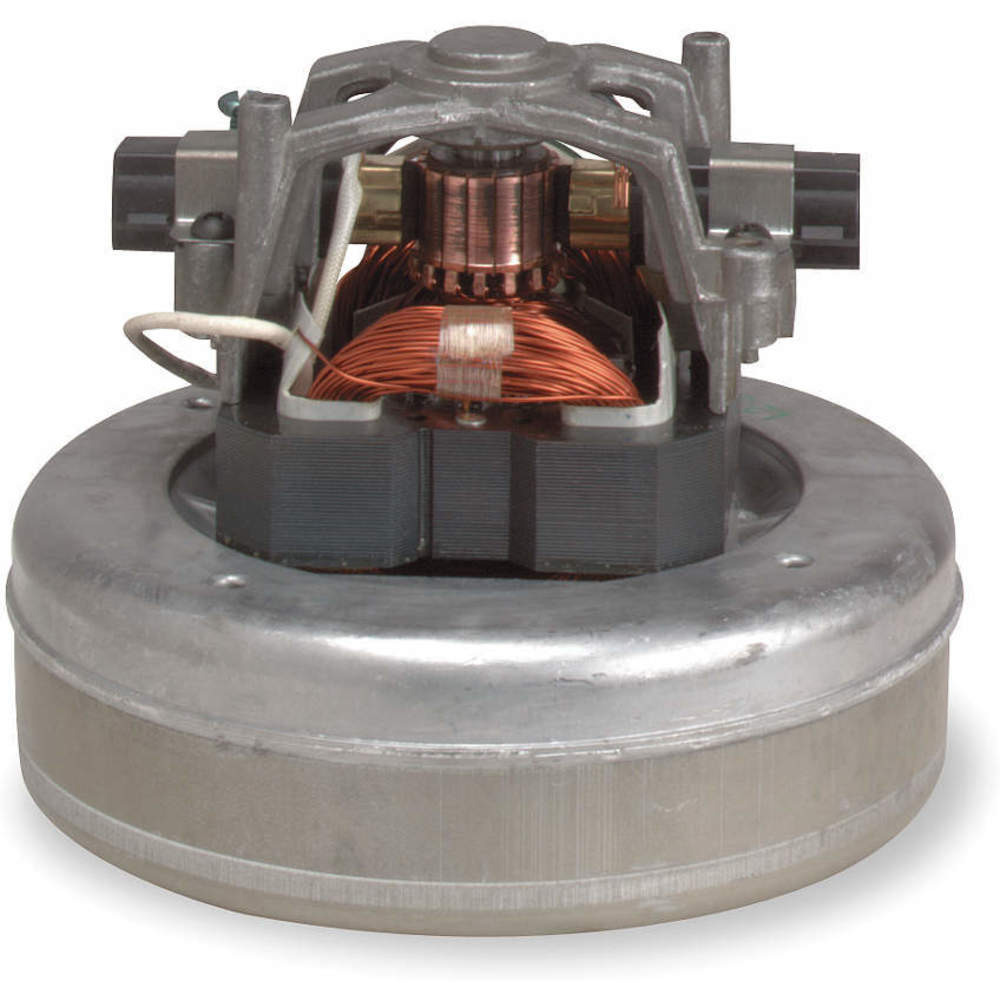

Thru-Flow Discharge Vacuum Motors

Ametek Lamb thru-flow discharge vacuum motors are ideal for use with canister / utility and central vacuum systems to move dry & clean air. These intermittent-duty motors feature an open / open drip-proof enclosure to prevent motor overheating and ball bearings to prevent lubricant leakage and ingress of foreign particles into the casing. With an average life of 500 hours, they are capable of withstanding ambient temperatures up to 40 degrees C. Choose from a wide range of these thru-flow discharge vacuum motors available in 50 & 60 Hz frequency variants on Raptor Supplies.

Ametek Lamb thru-flow discharge vacuum motors are ideal for use with canister / utility and central vacuum systems to move dry & clean air. These intermittent-duty motors feature an open / open drip-proof enclosure to prevent motor overheating and ball bearings to prevent lubricant leakage and ingress of foreign particles into the casing. With an average life of 500 hours, they are capable of withstanding ambient temperatures up to 40 degrees C. Choose from a wide range of these thru-flow discharge vacuum motors available in 50 & 60 Hz frequency variants on Raptor Supplies.

| Style | Model | Voltage | Motor Enclosure Design | Blower Stages | Cfm @ 2-In. Orifice | Thermal Protection | Max. Air Watts | No. Of Speeds | Overall Height | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 116846-00 | €247.49 | |||||||||

| B | 116432-00 | €199.70 | |||||||||

| B | 116227-00 | €211.79 | |||||||||

| C | 116881-50 | €113.72 | |||||||||

| D | 116884-49 | €171.23 | |||||||||

| E | 119411-00 | €120.16 | |||||||||

| B | 119402-00 | €138.86 | |||||||||

| F | 119347-00 | €141.33 | |||||||||

| B | 116669-50 | €162.79 | |||||||||

| A | 116457-00 | €169.72 | |||||||||

| A | 115737 | €171.93 | |||||||||

| A | 115750 | €187.90 | |||||||||

| G | 116297-00 | €132.39 | |||||||||

| B | 115744 | €195.02 | |||||||||

| H | 116309-00 | €116.44 | |||||||||

| I | 116311-01 | €150.43 | |||||||||

| J | 116146-00 | €190.99 | |||||||||

| D | 115923 | €180.08 | |||||||||

| K | 119400-00 | €95.75 | |||||||||

| J | 115982 | €172.32 | |||||||||

| B | 115756 | €191.89 | |||||||||

| A | 116111-00 | €202.72 | |||||||||

| H | 116668-50 | €142.07 | |||||||||

| A | 116670-50 | €170.04 | |||||||||

| C | 116882-50 | €125.05 |

Motor, 1 HP, 3 Phase, 575V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522925000 | CV9YQR | €1,491.24 | RFQ |

Motor, 1 HP, 3 phase, 230/460V, Tefc

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517340000 | CV9YNG | €3,374.15 | RFQ |

Motor, 2 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517341000 | CV9YNH | €3,374.15 | RFQ |

Motor, 3 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517342000 | CV9YNJ | €3,192.70 | RFQ |

Motor, 4 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517343000 | CV9YNK | €5,167.28 | RFQ |

Motor, 0.5 HP, 42 Frame Size, 1 Phase, 115/230V. TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517355000 | CV9YNL | €1,216.08 | RFQ |

Motor, 0.5 HP, 42 Frame Size, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517356000 | CV9YNM | €1,034.55 | RFQ |

Motor, 1.5 HP, 3 Phase, 575V, XP

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517391000 | CV9YNN | €4,229.38 | RFQ |

Motor, 1 HP, 1 Phase, 115/230V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517476000 | CV9YNX | €1,505.15 | RFQ |

Motor, 3 HP, 3 Phase, XP

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 517675000 | CV9YPE | €6,017.11 | RFQ |

Motor, 4 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522919000 | CV9YQN | €2,085.96 | RFQ |

Motor, 1 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522921000 | CV9YQP | €1,216.36 | RFQ |

Motor, 1/3 HP, 3 Phase, 230/460V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522922000 | CV9YQQ | €1,143.86 | RFQ |

Motor, 0.5 HP, 3 Phase, 575V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522926000 | CV9YQT | €1,491.04 | RFQ |

Motor, 0.5 HP, 1 Phase, 115V, ODP

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 516905000 | CV9YMJ | €1,284.81 | RFQ |

Motor, 3 HP, 3 Phase, 575V, TEFC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 522957000 | CV9YQX | €3,623.95 | RFQ |

Motor, 5 HP, 3 Phase, 230V, XP

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 523462000 | CV9YRW | €11,525.74 | RFQ |

Motor, 1.5 HP, 3 Phase, XP

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 528752000 | CV9YTU | €5,810.47 | RFQ |

Features

- Ametek Lamb vacuum motors operate efficiently within an ambient temperature range of up to 40 degrees Celsius.

- They are equipped with ball bearings for smooth and reliable operation over an extended period.

- These single-phase vacuum motors are designed for intermittent duty and are suitable for applications where the motor operates in cycles rather than continuously.

- Their open dripproof enclosure design enhances ventilation and prevents the ingress of moisture and contaminants.

- Thru-flow discharge vacuum motors do not require a cooling fan. They move sucked air around the motor to dissipate heat.

- Tangential discharge vacuum motors permit air to flow into the bottom of the motor and through an air tube on the side.

- Peripheral discharge vacuum motors are powder-coated to avoid rusting.

Working Mechanism

- When the user power on the motor, it rapidly spins the impeller.

- As the impeller moves, it draws air into the vacuum chamber via the intake port.

- The impeller rotation creates centrifugal force, accelerates the airflow, and pushes it towards the outlet port.

- Meanwhile, the pressure inside the vacuum chamber decreases due to the creation of the partial vacuum.

- This pressure differential between the inside of the chamber and the external environment causes air to rush through the intake port.

- This rushed air carries any particles or debris in the vicinity.

- The airflow then passes through a filtration system, which traps the particles while allowing clean air to pass through.

Standards and Approvals

- UL

- CSA

Frequently Asked Questions

What factors should be considered when selecting an Ametek Lamb vacuum motor?

Factors to consider when selecting a vacuum motor include ambient temperature range, duty cycle, bearing type, motor enclosure design, power requirements and airflow capacity.

What is a one-stage vacuum motor?

One-stage vacuum motors have a single impeller or fan blade that generates both airflow and suction in a single stage. As the impeller rotates, it draws air into the vacuum chamber through an intake port, creating a partial vacuum that sucks in dirt, dust and debris. These motors are generally simpler in design and more compact than multi-stage motors, making them suitable for lighter-duty applications.

What are two-stage vacuum motors?

Two-stage vacuum motors feature two impellers arranged in series. Each stage contributes to the generation of suction. In the first stage, the impeller accelerates airflow, while in the second stage, the air is compressed to increase suction power. This dual-stage design allows two-stage motors to deliver higher suction levels and airflow than one-stage motors. They are commonly used in material handling and HVAC systems where greater suction power is essential.

What are three-stage vacuum motors?

Three-stage vacuum motors come with three impeller stages. Similar to two-stage motors, the first stage accelerates airflow, the second stage further compresses the air and the third stage maximises suction power. Three-stage motors are perfect for heavy-duty applications like large-scale material handling equipment and high-performance cleaning machines.

What is an open dripproof enclosure?

An open dripproof enclosure, also known as an ODP enclosure, allows for adequate ventilation while protecting against moisture and debris ingress. In an ODP enclosure, the motor's internal components are exposed to the surrounding environment. The enclosure design prevents dripping liquids or falling debris from directly contacting the motor windings or other critical parts. This enclosure allows airflow for cooling the motor during operation, helping to prevent overheating and ensuring optimal performance.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- TORNADO

- Condensate Pump Accessories

- Shaft Adapters

- Strapping Cutters

- Drill Presses

- Calibration Solutions

- DAYTON Boxes

- SPEARS VALVES CPVC True Union Industrial Horizontal 3-Way Full Port Ball Valves, Spigot, EPDM

- ZURN Diaphragm Assembly

- MANITOWOC Agitators

- ASHCROFT E Bimetallic Thermometer, 3 Inch External Adjust, Rear Connection

- CAMLOCK FITTINGS Type DP Cam And Groove Dust Plugs

- MILLER ELECTRIC Performance Series TIG Welding Gloves

- MCR SAFETY Mustang Leather Welding Work Gloves