These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Power Tools

- Power Drills

- Milling and Drilling Machines

Milling And Drilling Machines

<p>Milling and drilling machines are machining tools used in the manufacturing and metalworking industries to cut, shape & drill holes in a workpiece made of metal, wood or other materials. </p>

Tissue Grinders

| Style | Model | Capacity | Size | Price (ex. VAT) | Pkg. Qty. | |

|---|---|---|---|---|---|---|

| A | 2305-2800SS | €310.00 | 50 | |||

| B | 6751 | €565.77 | 1 |

Grinding Mills

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM100/1 | €1,837.69 | RFQ | |

| A | DRILL-HM100/2 | €1,837.69 | RFQ |

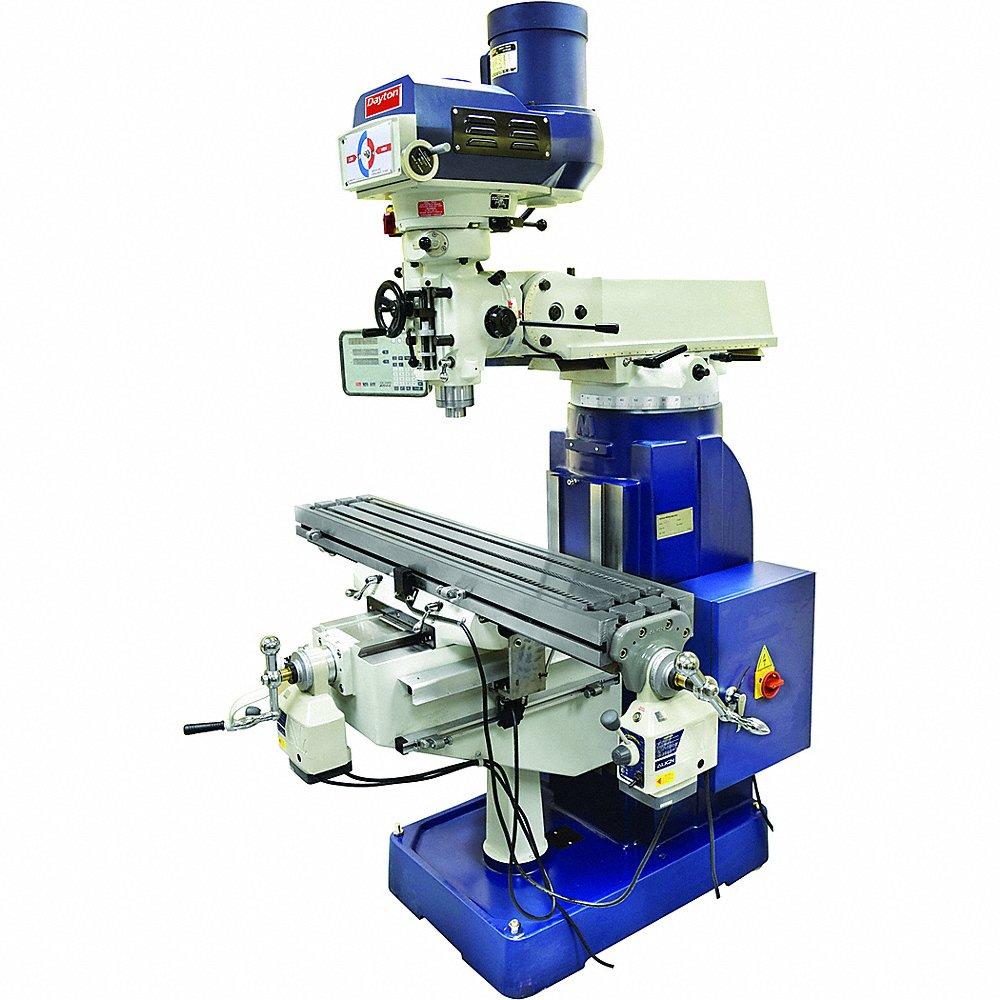

Geared Drilling Milling Machine

CNC Mills

Vertical Turret Mills

Gear Head Milling Machines

Heavy Duty Gear Head Drilling Machines

Variable Speed Milling Machines

| Style | Model | voltage | hp | spindle speed | Phase | Spindle To Table | Operation | Head | Table Work Surface | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 690407 | €29,416.55 | RFQ | ||||||||

| B | 691205 | €22,555.26 | RFQ | ||||||||

| C | 690120 | €20,554.77 | RFQ | ||||||||

| D | 690940 | €63,966.66 | RFQ | ||||||||

| E | 690087 | €20,123.52 | RFQ | ||||||||

| F | 690099 | €23,808.25 | RFQ | ||||||||

| G | 690107 | €20,123.52 | RFQ | ||||||||

| F | 690202 | €18,566.25 | RFQ | ||||||||

| H | 690948 | €51,508.50 | RFQ | ||||||||

| I | 690117 | €22,555.26 | RFQ | ||||||||

| F | 690098 | €21,501.11 | RFQ | ||||||||

| J | 690183 | €17,197.04 | RFQ | ||||||||

| K | 690408 | €21,561.00 | RFQ | ||||||||

| F | 690161 | €19,433.52 | RFQ |

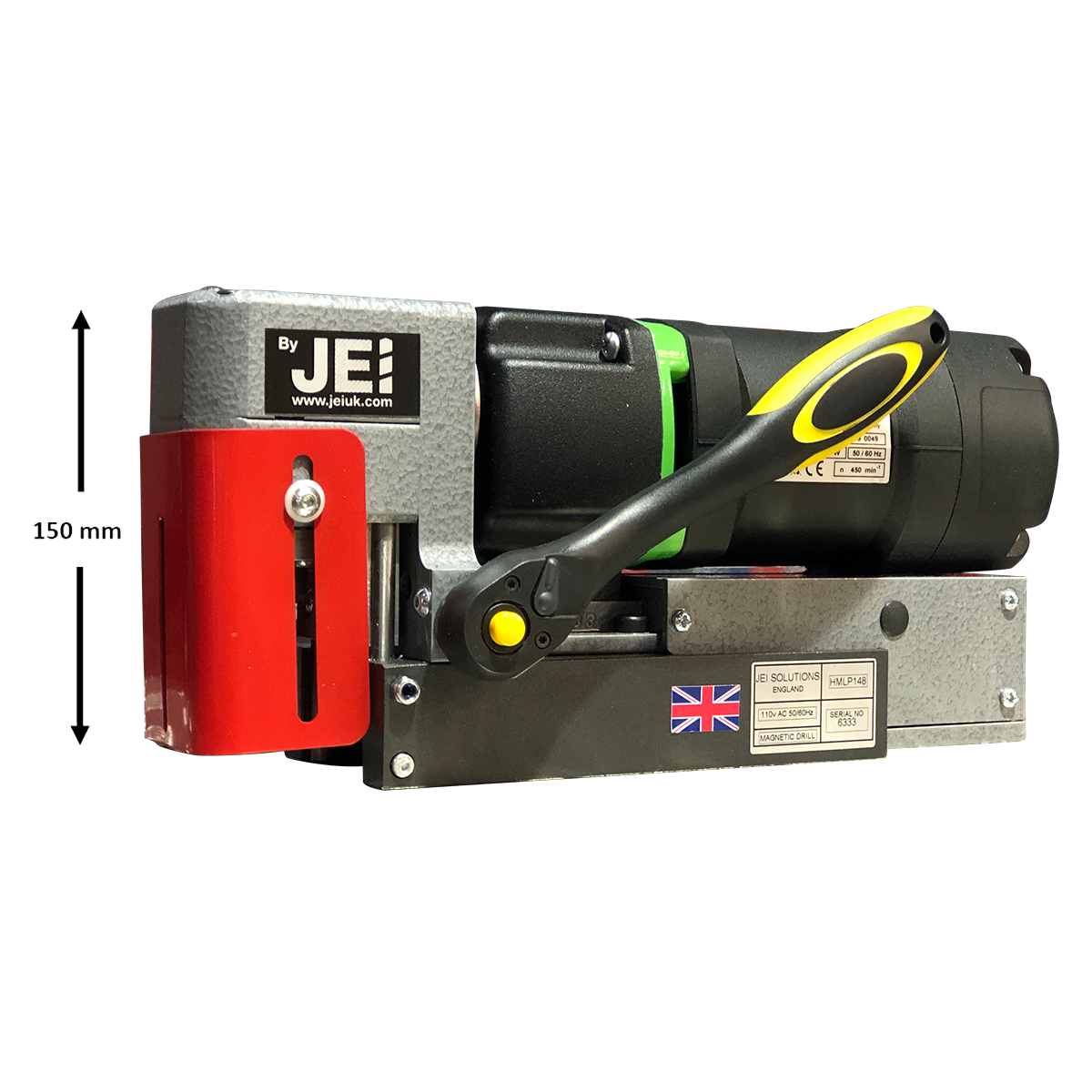

Mill/Drill Machines

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-MB5/1C | €11,079.49 | RFQ | |

| A | DRILL-MB5/2C | €11,079.49 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM140T/1 | €4,933.17 | RFQ | |

| A | DRILL-HM140T/2 | €4,933.17 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM100T/1 | €2,099.37 | RFQ | |

| A | DRILL-HM100T/2 | €2,099.37 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM50T/1 | €1,573.06 | RFQ | |

| A | DRILL-HM50T/2 | €1,573.06 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM50/1 | €1,404.81 | RFQ | |

| A | DRILL-HM50/2 | €1,404.81 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-HM40EX/1 | €936.54 | RFQ | |

| A | DRILL-HM40EX/2 | €936.54 | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-ULP/1 | €1,622.61 | RFQ | |

| A | DRILL-ULP/2 | €1,622.61 | RFQ |

Vials

| Style | Model | Labware Body Material | Labware Clarity | Autoclavable | Closure Material | Glassware Class | Includes Closure | Labware Basic Material | Labware Closure Liner Design | Price (ex. VAT) | Pkg. Qty. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 6808 | €2,994.67 | 1 | |||||||||

| B | 2241-PEF-200 | €320.21 | 200 | |||||||||

| C | 2253-PC-48 | €468.01 | 48 | |||||||||

| D | 2241R-PEF | €469.78 | 200 |

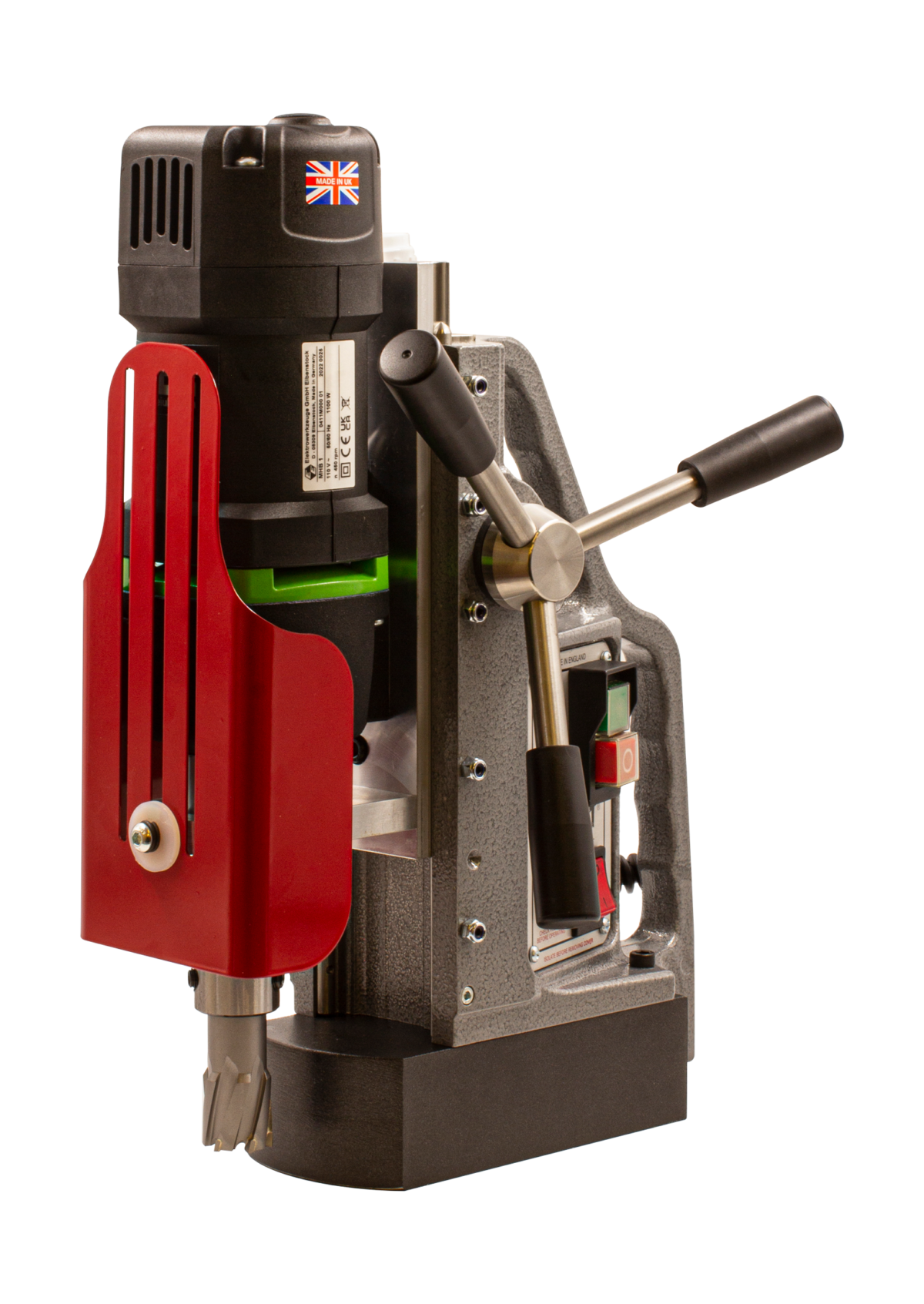

Airbeast Drilling Machine

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-AIR35/ATEX | €5,942.67 | RFQ | |

| B | DRILL-AIR45/ATEX | €7,350.75 | RFQ | |

| C | DRILL-AIR200 | - | RFQ |

| Style | Model | MPN | Price (ex. VAT) | |

|---|---|---|---|---|

| A | DRILL-LP45/1 | €1,600.83 | RFQ | |

| A | DRILL-LP45/2 | €1,600.83 | RFQ |

Working Mechanism

Milling Machines

- Milling machines use rotary cutters to remove material from a workpiece.

- The workpiece is clamped onto a table or fixture and the rotary cutter spins at high speed, removing material as it moves along the workpiece.

- The cutter can be moved in different directions, allowing for precise cuts and shaping.

Drilling Machines

- Drilling machines use a rotating drill bit to make holes in a workpiece.

- The workpiece is clamped onto a table and the drill bit is positioned above it.

- The drill bit is then lowered onto the workpiece and the motor rotates it at a high speed to create a hole.

Frequently Asked Questions

How to ensure safety while operating a milling or drilling machine?

Safety precautions include wearing proper protective gear, following machine instructions and ensuring proper machine & tool setup.

How to maintain a milling or drilling machine?

Regular maintenance includes lubricating moving parts, cleaning chips & debris and checking & replacing worn components.

What is the role of spindle speed in milling and drilling?

Spindle speed determines how quickly the cutting tool rotates and how fast it cuts through the material. Users must optimise the spindle speed to achieve the desired result without damaging the tool or workpiece.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- USA SEALING

- KEYSHAFT

- Temperature Controlled Rooms

- Mailbox Posts

- Gauge Cocks

- Grooved Pins

- Pressure Gauge Panel Mount Kits

- GENERAL ELECTRIC SGLC Frame Circuit Breaker

- WEG ACB-Series Caps

- DIXON Frl Regulator Panel Nuts

- EBERBACH E3300 Series Single Speed Mini Cutting Mills

- DESTACO 207 Series Vertical Hold Down Clamps, Straight Base, U Bar

- PROTO Impact Socket, 1 Inch, Imperial, Heat Treated Alloy Steel

- ML KISHIGO High Visibility Vests, Orange

- IRONCLAD Kong Dexterity Supergrip Gloves