These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Hydraulics

- Pumps

- Hydraulic Two Stage Gear Pumps

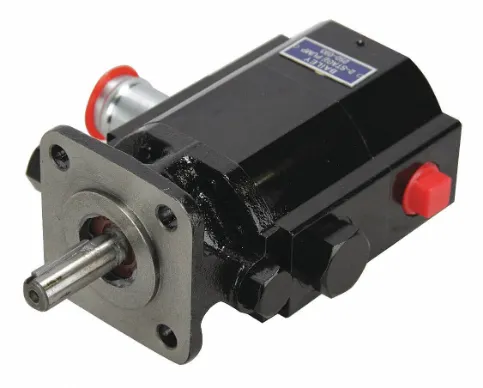

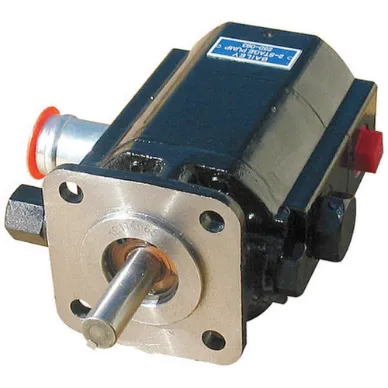

Hydraulic Two Stage Gear Pumps

Hydraulic two-stage gear pumps are designed to convert mechanical energy into hydraulic energy by using the motion of gears to move fluid through the system. They are ideally used in the

...Read moreHydraulic Gear Pumps

| Style | Model | Input Rpm | Shaft Dia. | Shaft Length | Price (ex. VAT) | |

|---|---|---|---|---|---|---|

| A | CBNA-8.8/3.6A | €365.01 | ||||

| B | 250092 | €332.71 | ||||

| C | 250093 | €395.15 |

Hydraulic Two Stage Gear Pumps

Hydraulic two-stage gear pumps, often called log splitter pumps, combine multiple flow lines at low pressures, but only use one pump when the pressure is high. Raptor Supplies offers an array of Chief and Haldex Barnes gear pumps used with presses, clamps and compactors. These pumps provide an automatic 2-speed operation; where the first stage unloads fully at 450 PSI while the second stage can go up to 3000 PSI. They are available in direct and external drive options.

Working Mechanism

- The 2-stage hydraulic gear pumps are designed to combine multiple flow lines at low pressures but use only one pump when the pressure in the system is high.

- The first stage of the pump consists of a smaller set of gears that creates a low-pressure flow of fluid.

- This low-pressure flow is then directed into the second stage of the pump, consisting of a larger set of gears that work together to increase the pressure of the fluid.

Frequently Asked Questions

What is a mounting flange in 2-stage gear pumps?

A mounting flange is a part of two-stage hydraulic pumps that provide a secure and stable mounting point while reducing vibration and ensuring the smooth functioning of the pump. It allows the installation and removal of the pump with minimal ease for maintenance and repair purposes.

What is the difference between direct and external drives?

- In direct drive configuration, the motor is mounted directly onto the pump housing. Here, both the motor and pump share a common shaft, allowing for a direct transfer of power from the motor to the pump. Direct drives are compact in size and simpler in design, making them easier to install and maintain.

- In external drive configuration, on the other hand, the motor and pump are separate entities that are connected by a coupling or belt drive. The motor is mounted outside of the pump housing and is connected to the pump through a mechanical linkage. External drives are more complex in size but offer greater flexibility in terms of motor selection and positioning.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- STRONG HAND TOOLS

- VELP SCIENTIFIC

- ROTRON

- KEYSHAFT

- Cable Controlled Gas Shut-Off Valves

- Screwdriver Accessories

- Air Hoses

- Polyurethane Tubing

- Reception Area Furniture

- NIBCO Twin Disk Check Valves

- DEVILBISS DeKups Adapters

- BUSSMANN AG Glass Fuses

- BALDOR / DODGE GTEZ Ball Bearings

- NIBCO Pipe Couplings, Polyvinylidene

- OIL SAFE Color Coded Drum Label Kits

- ML KISHIGO GF184 High Visibility Vest

- MEMPHIS GLOVE Cut Pro Cut Resistant Work Gloves, 10 Gauge

- AKRO-MILS 35180 Nest And Stack Totes

- LOC-LINE Female Npt Valve