These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Machining

- Machining Supplies

- Hydraulic Presses

Hydraulic Presses

Hydraulic presses are used in a wide range of industrial and manufacturing applications, such as forging, stamping, deep drawing and pressing. They use a fluid (oil) to generate a

...Read moreHydraulic Presses

Hydraulic Press

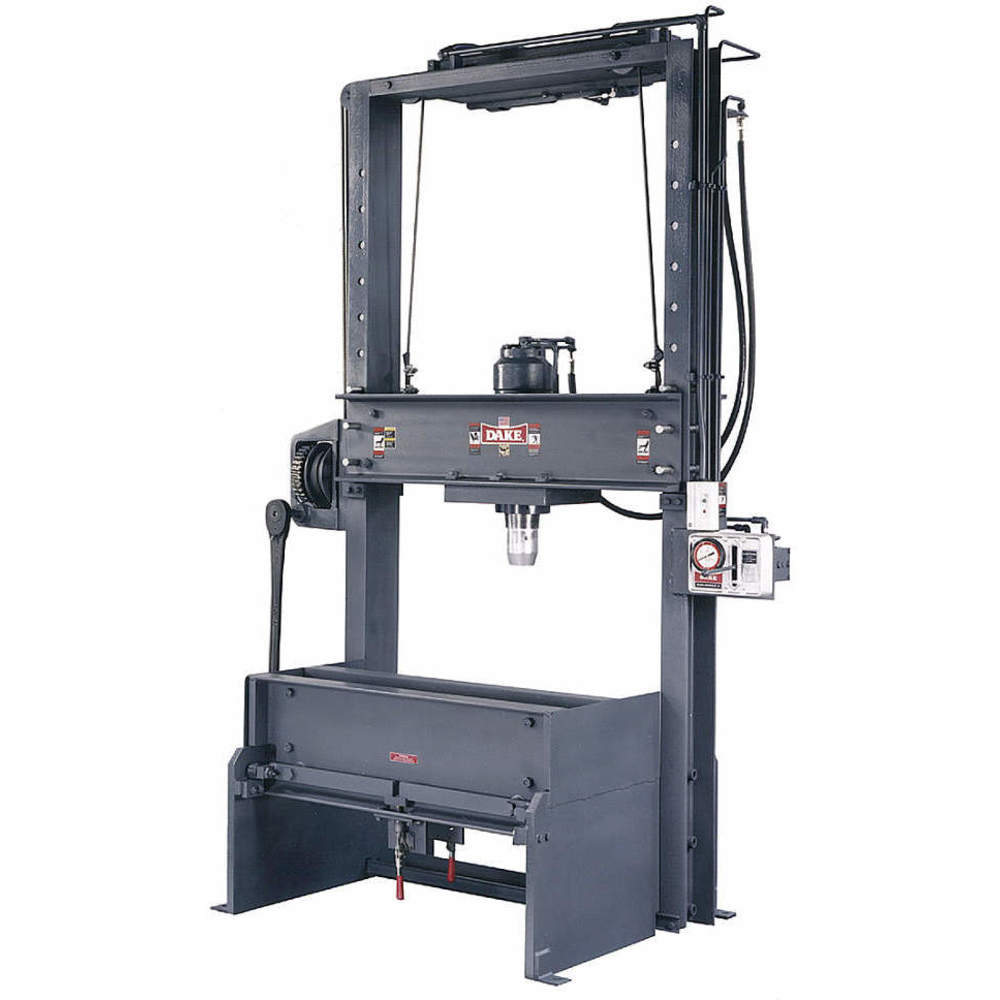

Double Acting, Movable Cylinder, H-Frame Hydraulic Press

Double Acting, Fixed Cylinder, H-Frame Hydraulic Press

| Style | Model | Frame Type | Frame Capacity | Cylinder Type | Overall Height | Height With Screw Extension | Reservoir Capacity | Ram Travel | Cylinder Stroke | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 909205 | €4,594.46 | RFQ | ||||||||

| B | 909215 | €5,968.96 | RFQ | ||||||||

| C | 909250 | €9,473.68 | RFQ | ||||||||

| D | 972003 | €12,808.63 | RFQ | ||||||||

| E | 972004 | €16,154.54 | RFQ | ||||||||

| F | 972005 | €19,270.45 | RFQ | ||||||||

| F | 972016 | €49,921.63 | RFQ | ||||||||

| F | 972017 | €86,113.26 |

Single Acting, Movable Cylinder, H-Frame Hydraulic Press

Single Acting, Fixed Cylinder, H-Frame Hydraulic Press

Hydraulic Presses

Hydraulic Press

Hydraulic Shop Press

Hydraulic Press

Indexable Profiling End Mill

20 Ton Shop Press

Electric Tire Presses

25 Ton Dual Stations

40 Ton Shop Press

20 Ton Horizontal Presses

60 Ton Shop Press

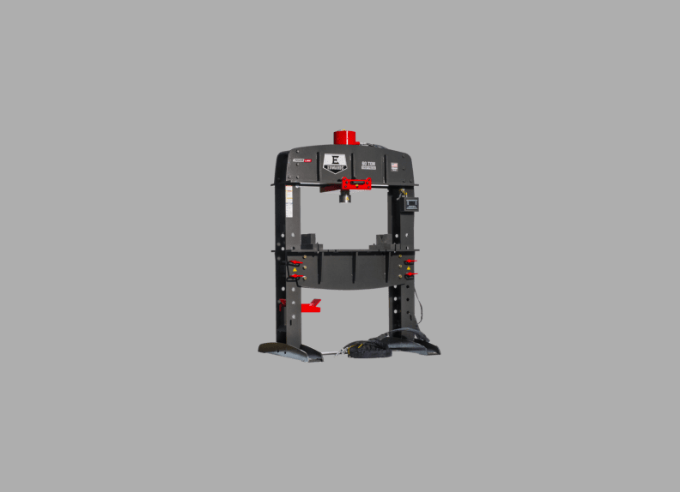

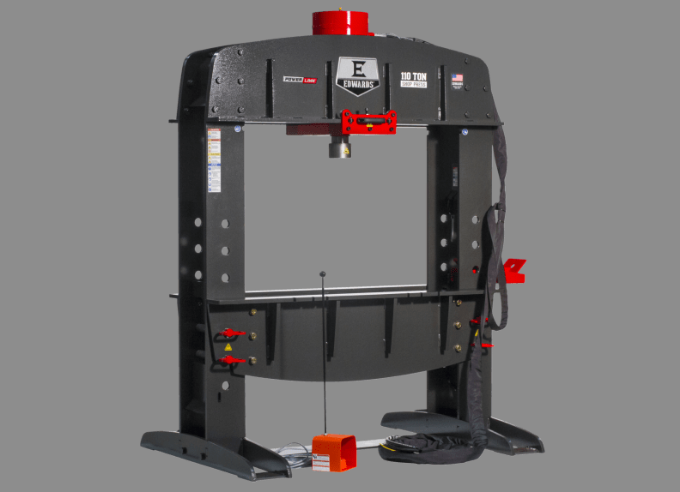

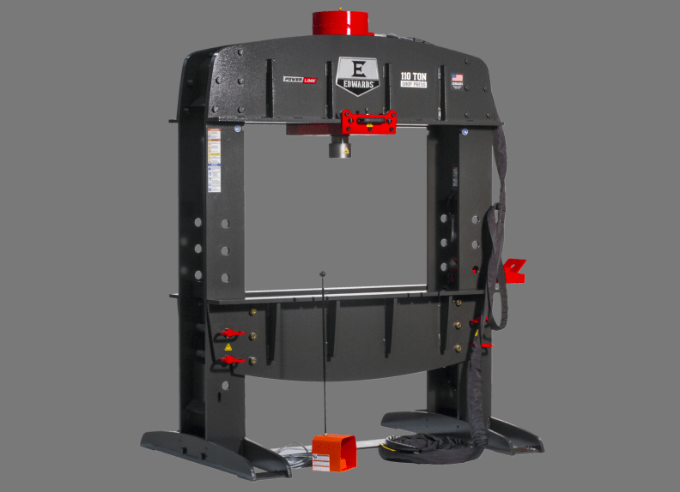

110 Ton Shop Press

Hydraulic Presses

We offer a wide range of hydraulic / arbor / C-clamp presses designed for applications in metal fabrication, cosmetic, pharmaceutical and glass manufacturing industries. For transforming metallic objects into sheets or thinning glass, these hydraulic press machines use a hydraulic cylinder to create a compressive force on the ram / piston which then transfers it to the fluid. Featuring a welded / bolted construction for maximum strength and durability, these hydraulic presses are offered in different frame capacities. Raptor Supplies offers a wide array of various hydraulic press manufacturers like Enerpac, Dake Corporation, Gray, Baileigh Industrial and OTC. For different applications, fixed / portable hydraulic press machines are available in movable, fixed, single-acting and double-acting cylinder options.

Working Mechanism

- Hydraulic presses use a pump to pressurise fluid, typically oil, which is then directed into a cylinder.

- The pressurised fluid then pushes a piston within the cylinder, creating a force that is transferred to a tool or dies attached to the cylinder.

- The resultant force generated by the press can be used to shape or form metals and other materials.

Features

Palmgren Hydraulic Presses :

- These hydraulic presses provide the high force required for riveting, squeezing, punching, and bending applications.

- They have a machined steel anvil for accurate work support in four different slot positions.

- These units feature an adjusting screw that accurately limits the depth of the ram stroke.

Dake Corporation H-Frame Hydraulic Presses :

- These electric hydraulic presses can handle large and bulky items, and the table height can be adjusted for proper positioning using the included lifting chain.

- They have three-point levers that allow users to control the ram with one hand.

- Their dual-acting cylinder moves the ram throughout the downstroke and return, allowing for precise alignment and smooth movement in both directions.

Enerpac Hydraulic Shop Presses:

- These double-acting hydraulic presses compress workpieces during clinching, moulding, punching, deep drawing, metal forming and forging operations.

- They feature welded construction with a Hydra-Lift bed for effortless vertical daylight adjustments and a roller head design for smooth movement.

- These Enerpac electric hydraulic presses also include a hydraulic clamp for locking the frame in place.

Frequently Asked Questions

What is the difference between single-acting and double-acting hydraulic presses?

- Single-acting presses have a single connection to a source of pressurised fluid and the other end is connected to a reservoir or return line.

- Double-acting presses, on the other hand, have two connections to a source of pressurised fluid, wherein one connection helps the cylinder to extend and the other let it retract during the operation.

What is the use of an H-frame hydraulic press?

The H-frame consists of two pillars that support the cylinder and the upper and lower platens. This design allows them to create better stability for tasks like stamping, punching, bending, cutting, forging, deep drawing and straightening metals or plastics. In addition, H-frame presses offer high precision, easy maintenance and the ability to withstand large loads.

Where are movable and fixed cylinders used?

- A movable cylinder moves about the press's frame where it needs to exert force on the workpiece. For example, in a stamping press, the cylinder moves downwards to apply force to the stamping die.

- Fixed cylinders are used in presses, where the cylinder is fixed on the punching plate while the workpiece is placed on a bed. In operation, the gliding screw provides an upward force while the cylinder provides a downward force to the upper body, causing the punching machine to move downwards with a greater impact and cut / shape the workpiece.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- QUIETCOOL

- RELAY AND CONTROL CORP

- Safety Can Accessories

- Push Brooms

- Enclosure Accessories

- Float Rods Adapters and Nuzzle Assemblies

- ORP Meters

- HOFFMAN Type 12 Stainless Steel Consolets

- MARTIN SPROCKET 3/8 Inch Drive 6 Point Metric Standard Impact Sockets

- SPEARS VALVES Labwaste CPVC P302 1/4 BEnds, 90 Deg. Street Elbows, H x Spig

- WINSMITH SE Encore Series, E24 Size, MDND Worm/Worm Double Reduction Speed Reducers

- SPEARS VALVES CPVC Butterfly Check Valves, Threaded Ends, EPDM

- DESTACO 5310 Series Horizontal Hold Down Clamps

- DWYER INSTRUMENTS 477B Series Handheld Digital Manometers

- CONDOR Knit Gloves, Full Finger, Full Dotted, 7 Gauge, Orange