These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Hydraulics

- Hydraulic System Components

- Hydraulic Flow Dividers

Hydraulic Flow Dividers

Hydraulic flow dividers are designed to distribute the single pump flow equally or in pre-defined ratios between 2 or more actuators. Raptor Supplies offers a wide range of hydraulic flow

...Read more| Style | Model | Flow Rate | Max. Outlet Pressure | Height | Function | Operating Pressure | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | AFT100-250/250-B-650 | €334.13 | ||||||

| A | AFT100-510/510-B-650 | €343.84 |

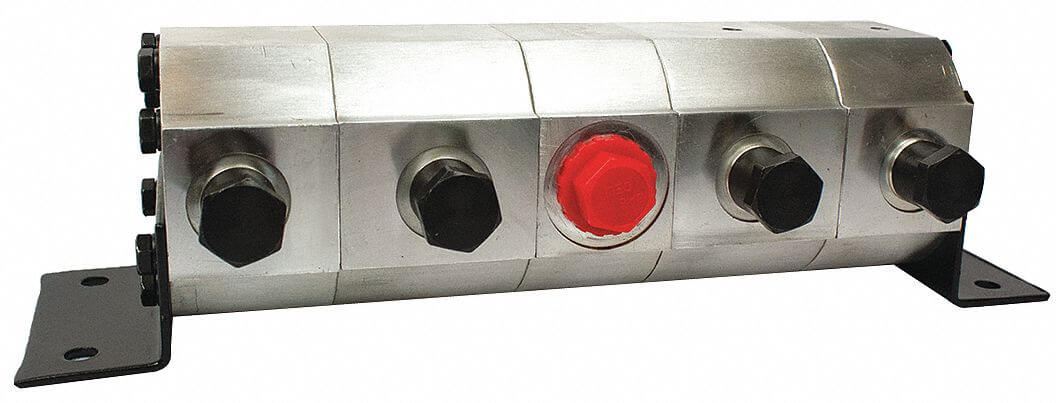

Hydraulic Flow Divider Rotary Gear

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| FM-4R4.2S | AH4UVY | €1,196.02 |

Hydraulic Flow Divider, 3/4 Inch NPT, 20 gpm to 35 gpm, 1, 1, Flow Divider, 3/4 Inch NPT

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| PDC-75-50 | AK7PYD | €295.02 |

GRESEN Hydraulic Flow Divider, Cast Iron, 5.51 Inch Length, 1.87 Inch Width

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| PDC-12-50 | CT7GLH | €287.80 |

Hydraulic Flow Dividers

Hydraulic flow dividers distribute the flow coming from a single pump, equally or in pre-defined ratios, amongst 2 or more actuators. Raptor Supplies offers a wide range of hydraulic flow dividers from Chief and Haldex. These rotary gear type flow dividers are used to synchronise 2 parallel motions hydraulically rather than mechanically. They feature permanently moulded cast iron construction capable of withstanding operating pressure up to 3000 PSI and an integral differential relief valve for reducing built-up pressure inside. The 11 tooth hardened steel gears can rotate at a maximum speed of 4500 RPM, delivering an outer liquid pressure of 4500 PSI. Choose from a wide range of hydraulic flow dividers, available in 2.4 to 5, 2.5 to 5, 5 to 10 and 10 to 20 GPM flow ratings.

Features

Haldex Barnes 1100042 Flow Dividers:

- It features moulded cast iron construction for structural rigidity and easy cleaning.

- This flow divider has an integral differential relief valve to limit the differential pressure between two unmixable fluids.

- It comes with 11-tooth-hardened steel gears for ease of operation.

- This flow divider offers flow rates ranging from 10 to 20 GPM.

- Models such as, 1020075 and 1020076 flow dividers offer flow rates of 2.4 to 5 GPM and 5 to 10 GPM respectively.

Chief FM-4R4.2S Hydraulic Flow Divider:

- This flow divider has aluminium construction to resist corrosion on exposed surfaces.

- It features a flow divider valve to maintain equal flow to two or more actuators.

- This flow divider offers flow rates ranging from 2.5 to 5 GPM.

Frequently Asked Questions

How are hydraulic flow dividers installed?

- Determine the flow rate requirements for each outlet.

- Choose the appropriate type of flow divider for your application.

- Mount the flow divider securely in the hydraulic system, aligning the ports.

- Connect the hydraulic lines using appropriate fittings and hoses.

- Test the flow divider to ensure even flow distribution and make adjustments if necessary.

- Regularly monitor and maintain the flow divider and hydraulic system for optimal performance.

How do I choose the correct hydraulic flow divider for my hydraulic system?

- Determine required flow rates and choose a divider that can handle them.

- Choose a divider with the correct number of outlets.

- Ensure the divider can handle the hydraulic system's maximum operating pressure.

- Choose a more accurate divider if precision is necessary.

- Choose a durable and low-maintenance divider.

- Confirm compatibility with other hydraulic components.

How to clean and maintain hydraulic flow dividers?

- Regularly inspect for damage, leaks or corrosion.

- Keep it clean by wiping it down.

- Ensure clean hydraulic fluid and replace filters regularly.

- Check and maintain lubrication.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- PRO WELD

- KEYSHAFT

- GRK

- High Temperature Lead Wire

- Nippers and Nibblers

- Wares and Tray Drying Racks

- Class T Fuses

- Plastic U-Shaped Channel Stock

- KURIYAMA K7300 Series, Reinforced Tubing, Shore A: 73

- TURTLESKIN CP Apron

- DIXON Compression Union Reducers

- APPLETON ELECTRIC Wall Mount Metal Halide Light Fixture

- START INTERNATIONAL ZCM1000 Series, Industrial Tape Dispensers

- CONDOR Leather Gloves, Cowhide, Premium, Full Finger, Gray

- CONDOR Rain Poncho Reuseable Rainwear

- AKRO-MILS 30080 Shelfmax Shelf Bins