These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Material Handling

- Drums

- Drum Lifters

MORSE DRUM Drum Lifters

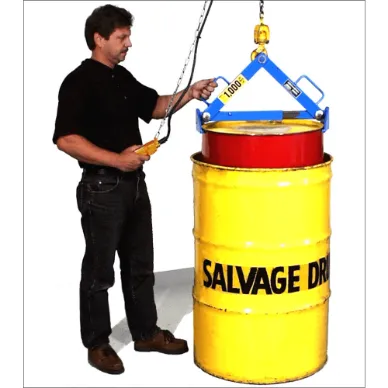

Morse drum lifters and dispensers are ideal for pouring contents from metal, plastic & fibre drums and assisting in lifting & transporting applications. They are factory tested for handling loads up to 125 per cent of the rated capacity. These drum lifters offer a positive-grip web strap and feature ratchet mechanism for secure fastening of the drums.

Morse drum lifters and dispensers are ideal for pouring contents from metal, plastic & fibre drums and assisting in lifting & transporting applications. They are factory tested for handling loads up to 125 per cent of the rated capacity. These drum lifters offer a positive-grip web strap and feature ratchet mechanism for secure fastening of the drums.

Drum lifters are designed to lift and transport heavy drums containing chemicals or other liquids. These machines are employed in the manufacturing, warehousing and chemical processing

...Read moreCustom Drum Lifters

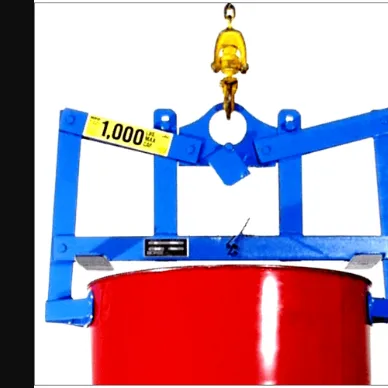

42 Series Heavy-Duty Drum Lifters

42 Series heavy-duty drum lifters by Morse Drum are suitable for lifting 55-gallon steel drums using hoists or cranes. These drum lifters offer both horizontal and off-vertical mode of operation for upending and setting the drum down on its side. They are further integrated with forged hooks for engaging the rims at opposite ends of the drum and can handle loads up to 2000 lb.

42 Series heavy-duty drum lifters by Morse Drum are suitable for lifting 55-gallon steel drums using hoists or cranes. These drum lifters offer both horizontal and off-vertical mode of operation for upending and setting the drum down on its side. They are further integrated with forged hooks for engaging the rims at opposite ends of the drum and can handle loads up to 2000 lb.

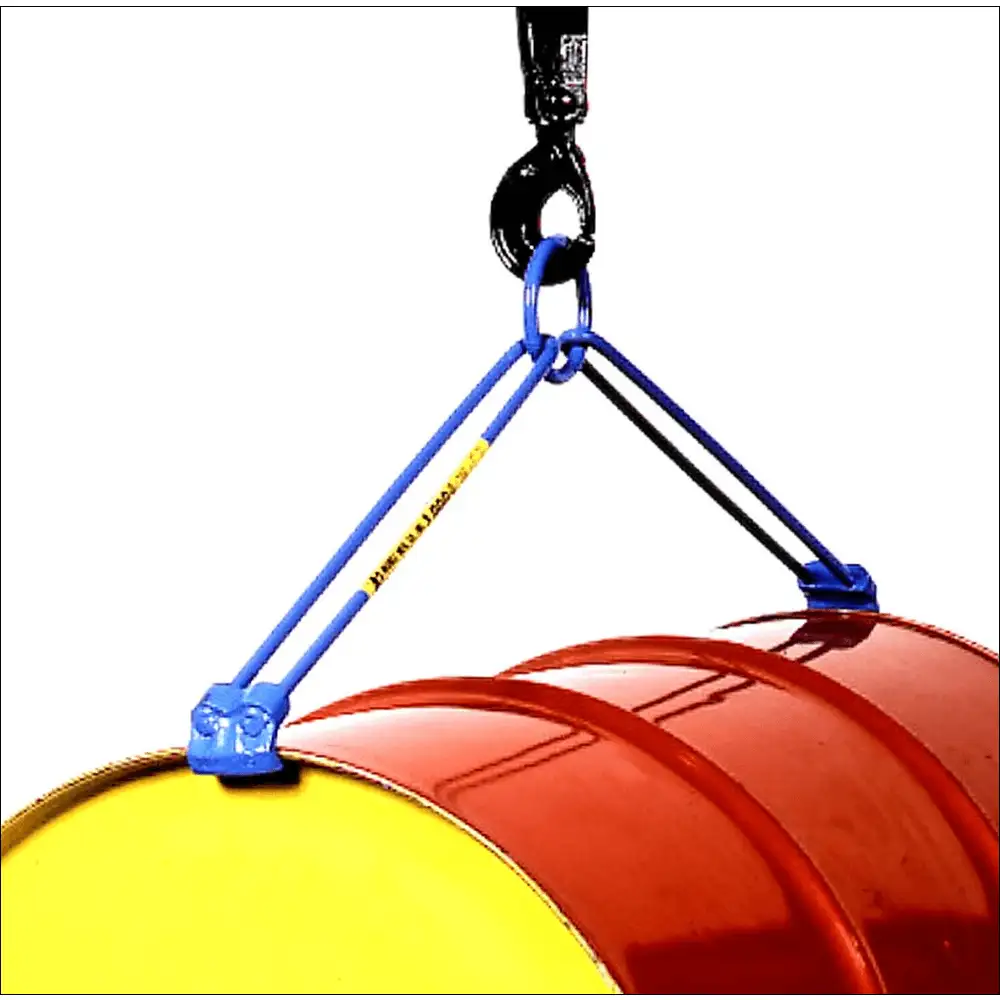

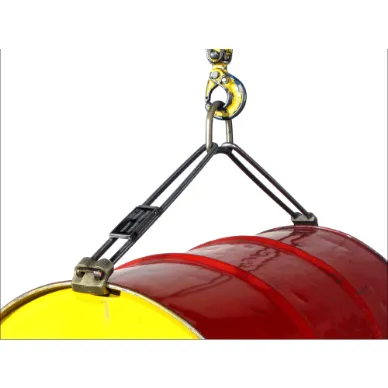

41 Series Lifting Hooks

Morse Drum 41 Series lifting hooks are designed for lifting and transporting drums or barrels safely. They feature steel lifting rings and steel rods for structural rigidity and heat-treated iron hooks for toughness and wear resistance. These steel hooks can withstand loads up to 1000lb and come in spark-resistant and normal variants.

Morse Drum 41 Series lifting hooks are designed for lifting and transporting drums or barrels safely. They feature steel lifting rings and steel rods for structural rigidity and heat-treated iron hooks for toughness and wear resistance. These steel hooks can withstand loads up to 1000lb and come in spark-resistant and normal variants.

92 Series Below-Hook Drum Lifters

90 Series Verti-Karrier Below Hook Drum Lifters

86 Series Below Hook Drum Lifters

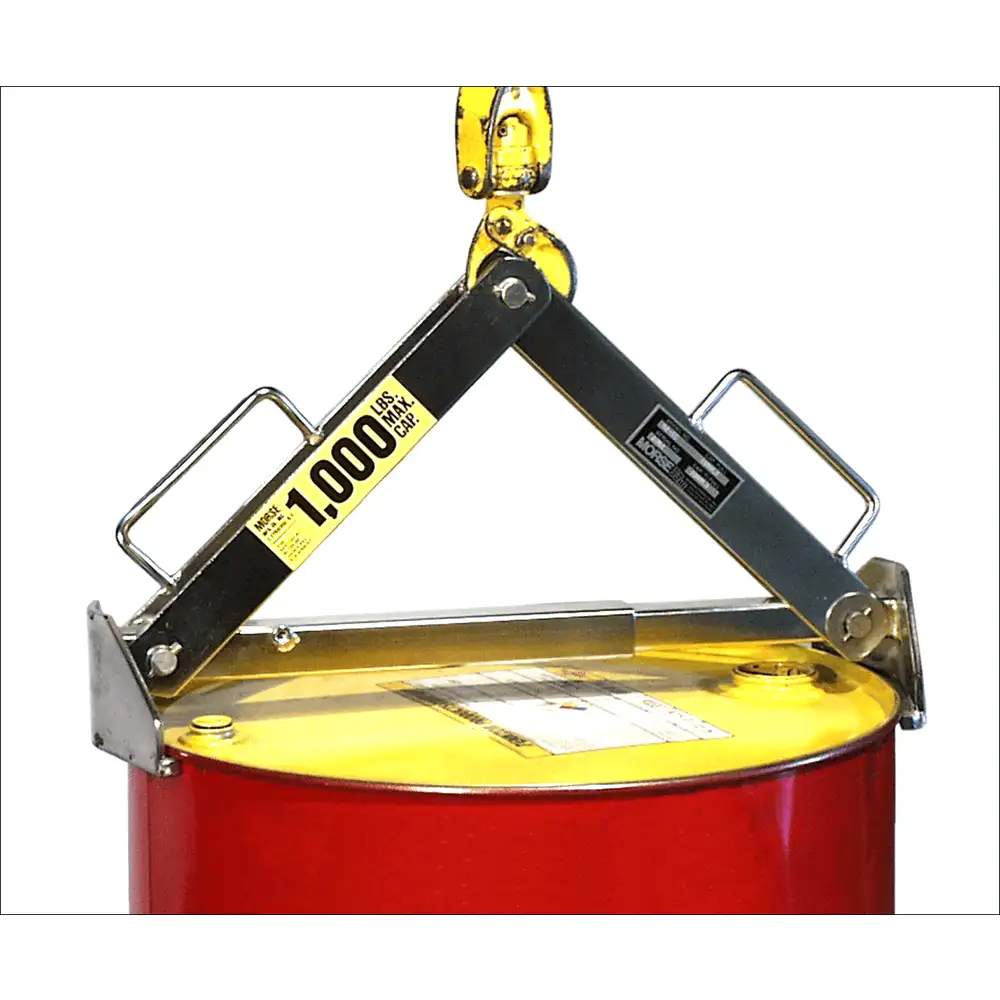

Below-Hook Drum Lifter, 208/322 Litre, Steel, 454 kg Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 91 | AF6EYR | €215.92 |

Features

- Morse drum lifters are capable of handling loads up to 2000 lb.

- They have a positive-grip web strap & ratchet mechanism for secure fastening to the drums.

- These units make use of a hoist, clinch or crane to lift the drums.

- The below hook lifters of selected models offer additional support & safety while lifting.

- Morse Drum Verti-Karrier lifters feature an alternating gripping facility that lifts the drums by grasping below the top rims and an automatic locking mechanism to prevent accidental release of the loads.

- Some models like horizontal drum lifting hooks have a tight head that remains intact throughout and a removable top with a lid to securely clamp the assembly. These models are further integrated with stainless-steel rods and spark-resistant aluminium / alloy bronze lifting rings & hooks.

- The 42 Series lifters offer both horizontal and off-vertical modes of operation for upending & setting the drum down on its side.

- Some models include slim-profile grippers to lower a drum into an overpack or a salvage drum and feature a self-adjusting tong-like action for automatic gripping.

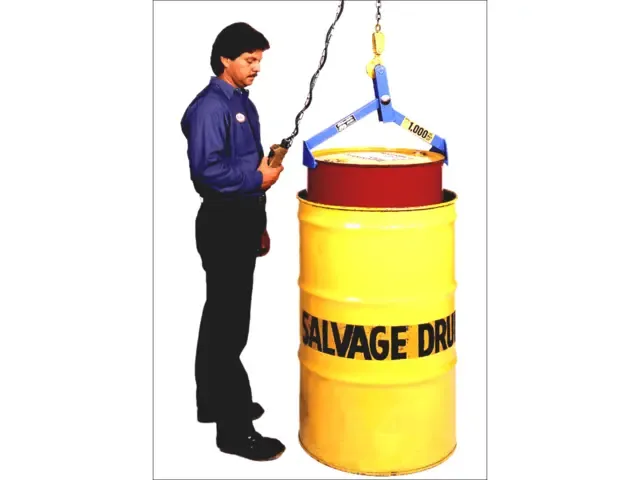

Working Mechanism

- The overhead drum lifters are easy & safe to operate in contrast to traditional lifting equipment.

- These lifters are used in conjunction with overhead cranes and a chain to hold & lift the drum using the rim.

- The directional flexibility of the drum depends upon the crane movement and can be easily repositioned / relocated / detached by unlocking the drum lifter's locking mechanism.

- If the requirement is to lift & transport drums with or without the upper rim, portable drum lifters are an ideal choice.

- These hydraulic drum lifters feature swivel casters for reducing the frictional losses on factory floors.

- They can also tilt / rotate the drum, allowing the inner content to flow easily.

Standards and Approvals

- ANSI

- ASME

- AWS

Frequently Asked Questions

What precautions should be taken before handling a drum?

- Before lifting / moving, the user should check for any damage and also ensure that the lid / cap is securely fastened.

- While handling drums containing hazardous powder / oil, the user should wear PPE kits.

- Drum lifters should be properly latched to prevent accidents & chances of injury caused by a drum fall.

What are the safety tips to be followed while handling drums?

- Heavy drums should be handled with proper drum handling equipment, like below-hook drum lifters, drum trucks or forklift attachments.

- Conditions like uneven or slippery floors and restricted spaces can entail greater risks. Plastic and fibre drums should be handled with utmost care in such situations.

- One should be extremely careful when using a forklift. The blades on the forklift can easily pierce through the drum and can cause spillage.

What are the suitable conditions for using Morse Drum overhead drum lifters?

Morse overhead drum lifters are suitable for applications where drums can only be lifted in an upright position. Additionally, they are used in facilities that have an integrated crane system for support during operation.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- TREGASKISS

- ALL MATERIAL HANDLING

- Moisture Testers

- Ground Rods

- TIG Torches

- Combination Starters

- Thread Turning Tools

- HARRIS Regulator Mounting Station

- BALDOR MOTOR Close Coupled Pump Motors, JM Type, Open Drip Proof, Single Phase

- BANJO T Handle

- BANJO Elbow, 45 Degrees, Polypropylene

- DESTACO 215 Series Horizontal Hold Down Clamps

- ANSELL 87-209 Alphatec Natural Rubber Latex Gloves

- ANSELL 70-225 Hyflex Reversible Cut Resistant Gloves

- OIL SAFE Spill Decks