These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Material Handling

- Drums

- Drum Lifters

Drum Lifters

Drum lifters are designed to lift and transport heavy drums containing chemicals or other liquids. These machines are employed in the manufacturing, warehousing and chemical processing

...Read moreFMDL Series Automatic Eagle Beak Drum Lifters

| Style | Model | Drum Material | Drum Type | Drum Size | Price (ex. VAT) | |

|---|---|---|---|---|---|---|

| A | FMDL-1 | €1,325.73 | ||||

| B | FMDL-2 | €1,739.06 | ||||

| C | FMDL-1-LDS-B1 | €1,439.92 | RFQ | |||

| D | FMDL-1-LDS-R3 | €1,427.05 | RFQ | |||

| E | FMDL-2-LDS-B1 | €2,174.11 | RFQ | |||

| F | FMDL-2-LDS-R3 | €2,150.93 | RFQ |

S-CB Series Counter-Balanced Drum Lifters

| Style | Model | Capacity | Width | Height | Color | Material | Style | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|

| A | S-CB-62-DDC | €15,484.80 | RFQ | ||||||

| B | S-CB-62-SDC | €15,193.50 | RFQ |

Ergomatic Standard Drum Handlers

| Style | Model | |

|---|---|---|

| A | ERGO 1000-SRJ-BC | RFQ |

| B | ERGO 1000-DH-BC | RFQ |

| B | ERGO 1000-DH-SRJ-BC | RFQ |

| C | ERGO HR 800-BC | RFQ |

| C | ERGO HR 800-SRJ-BC | RFQ |

| C | ERGO HR 800- DH-SRJ-BC | RFQ |

| D | ERGO-1000-OBS | RFQ |

| E | ERGO 1000 | RFQ |

| F | ERGO 1000-HE-PL | RFQ |

| G | ERGO DP 1500 | RFQ |

| H | ERGO 1000-SL | RFQ |

| I | ERGO-1500-DP-SL | RFQ |

DRUM Series Economy Portable Drum Lifter/Rotator/Transporters

| Style | Model | Caster Type | Depth | Hand Crank Rotation | Height | Rotation | Vertical Raised Height | Width | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | DRUM-LRT-EC | €2,538.51 | RFQ | |||||||

| B | DRUM-LRT-ESJ | €2,656.58 | RFQ |

Portable Drum Lifter

Level Lift Drum Dumpers

Valley Craft level lift drum dumpers with hand crank dumps ensure easy handling of 55-gallon steel drums. They feature heavy-duty welded frames for durability & strength and unique auto-drum levelling for raising or lowering of the drums. These forward dumping, dump handlers are equipped with 8 inch, polyethylene wheels & 4 inch, swivel casters, thereby ensuring control over the load & smooth manoeuvrability during transportation, respectively. They come with full 360 degrees forward or reverse rotation controls and have easy-to-load bonded rubber cradles for allowing operators to pour drum contents in a precise manner. The optional drum adapters can be attached to quickly convert the stranded cradles diameter from 23 inch to 18 inch for handling additional 30-gallon drums. Choose from a wide range of these dumpers, available in lengths up to 62 inches.

Valley Craft level lift drum dumpers with hand crank dumps ensure easy handling of 55-gallon steel drums. They feature heavy-duty welded frames for durability & strength and unique auto-drum levelling for raising or lowering of the drums. These forward dumping, dump handlers are equipped with 8 inch, polyethylene wheels & 4 inch, swivel casters, thereby ensuring control over the load & smooth manoeuvrability during transportation, respectively. They come with full 360 degrees forward or reverse rotation controls and have easy-to-load bonded rubber cradles for allowing operators to pour drum contents in a precise manner. The optional drum adapters can be attached to quickly convert the stranded cradles diameter from 23 inch to 18 inch for handling additional 30-gallon drums. Choose from a wide range of these dumpers, available in lengths up to 62 inches.

| Style | Model | Drum Dia. | Drum Type | Height | Length | Width | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | F88553C1 | €6,399.61 | RFQ | |||||

| A | F88561C1 | €6,981.93 | RFQ | |||||

| A | F88567B5 | €5,234.99 | RFQ | |||||

| A | F88568B4 | €5,817.30 | RFQ | |||||

| B | F88591B5 | - | RFQ | |||||

| C | F88590B6 | €10,009.95 | RFQ | |||||

| C | F88589B9 | €9,369.41 | RFQ | |||||

| D | F88581B7 | €11,291.04 | RFQ | |||||

| D | F88580B8 | €10,650.50 | RFQ | |||||

| E | F88577B3 | €3,488.05 | RFQ | |||||

| F | F88570C0 | €11,931.58 | RFQ | |||||

| F | F88569C3 | €11,291.04 | RFQ | |||||

| B | F88566C6 | €10,009.95 | RFQ | |||||

| B | F88564B8 | €9,369.41 | RFQ | |||||

| B | F88563B9 | €8,728.86 | RFQ | |||||

| B | F88592B4 | - | RFQ | |||||

| G | F88576B4 | €3,488.05 | RFQ | |||||

| H | F88585C3 | €13,794.98 | RFQ | |||||

| H | F88586C2 | €14,435.53 | RFQ | |||||

| H | F88587C1 | €15,716.61 | RFQ | |||||

| H | F88588C0 | €16,298.93 | RFQ |

Custom Drum Lifters

P-JIB Series Portable Cantilever Hoists

| Style | Model | Base Height | Capacity | Caster Material | Caster Size | Ground Clearance | Height | Item | Length | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | P-JIB-BALL-2 | €1,420.62 | RFQ | ||||||||

| B | P-JIB-BALL-4 | €2,197.16 | RFQ | ||||||||

| C | P-JIB-2 | €6,831.78 | RFQ | ||||||||

| D | P-JIB-4 | €7,537.73 | RFQ |

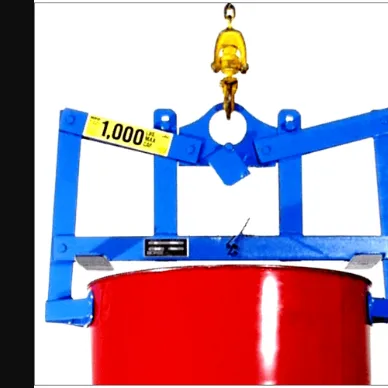

PDL Series Multi-Purpose Overhead Drum Lifters/Wrenches

| Style | Model | Color | Depth | Height | Material | Width | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | PDL-800-M | €197.53 | ||||||

| B | PDL-800-M-BR | €520.93 |

HDC-450 Series Hydraulic Drum Stackers

| Style | Model | Depth | Height | Motor Hp | Power Source | Rotation Type | Voltage | Width | |

|---|---|---|---|---|---|---|---|---|---|

| A | HDC-450-60 | RFQ | |||||||

| B | HDC-450-60-AC | RFQ | |||||||

| C | HDC-450-60-DC | RFQ | |||||||

| D | HDC-450-72-AC | RFQ | |||||||

| E | HDC-450-72-DC | RFQ | |||||||

| F | HDC-450-84 | RFQ | |||||||

| G | HDC-450-96 | RFQ | |||||||

| H | HDC-450-84-AC | RFQ | |||||||

| I | HDC-450-96-AC | RFQ |

CHDL Series Crane/Hoist Drum Lifters

42 Series Heavy-Duty Drum Lifters

42 Series heavy-duty drum lifters by Morse Drum are suitable for lifting 55-gallon steel drums using hoists or cranes. These drum lifters offer both horizontal and off-vertical mode of operation for upending and setting the drum down on its side. They are further integrated with forged hooks for engaging the rims at opposite ends of the drum and can handle loads up to 2000 lb.

42 Series heavy-duty drum lifters by Morse Drum are suitable for lifting 55-gallon steel drums using hoists or cranes. These drum lifters offer both horizontal and off-vertical mode of operation for upending and setting the drum down on its side. They are further integrated with forged hooks for engaging the rims at opposite ends of the drum and can handle loads up to 2000 lb.

Special Application Crane and Hoist Mounted Drum Handlers

High Volume Hoist and Crane Mounted Drum Handlers

Economical Hoist Mounted Drum Handlers

Single Drum and Double Drum Hoist Mounted Drum Handlers

| Style | Model | |

|---|---|---|

| A | 1-HCB-BC | RFQ |

| B | 2-HCB-BC | RFQ |

| C | 1-HCB-DCM-BC | RFQ |

| D | 2-HCB-DCM-BC | RFQ |

Heavy Duty Hoist Mounted Drum Handlers

| Style | Model | |

|---|---|---|

| A | 2-A-HD-BHDL | RFQ |

| B | 3-A-HD-BHDL | RFQ |

Ergomatic Power Drive Drum Handlers

| Style | Model | |

|---|---|---|

| A | ERGO 750-CB-PWPL | RFQ |

| B | ERGO 750-CB-PWPL-HR | RFQ |

| C | ERGO 750-CB-PWPL-SF | RFQ |

Portable Drum Lifter

Stainless Steel Drum Lifters

Vestil stainless steel drum lifters provide three-point drum contact with stabilising arms for lifting, stowing and transporting 30 & 55 gallon, steel or plastic drums. These units have strong & durable 304 SS construction and are quick & easy to operate by a single person. Drum lifters / transporters are ideal for pharmaceutical, washdown & cleanroom applications and allow the operator to load / unload drums on & off the pallets. They have a foot pump for raising / lowering and a straddle leg for allowing the drum lifter to glide over the pallet & grab the drum. Raptor Supplies offers a variety of these drum lifters for use with overhead hoist, cranes and forklift attachments.

Vestil stainless steel drum lifters provide three-point drum contact with stabilising arms for lifting, stowing and transporting 30 & 55 gallon, steel or plastic drums. These units have strong & durable 304 SS construction and are quick & easy to operate by a single person. Drum lifters / transporters are ideal for pharmaceutical, washdown & cleanroom applications and allow the operator to load / unload drums on & off the pallets. They have a foot pump for raising / lowering and a straddle leg for allowing the drum lifter to glide over the pallet & grab the drum. Raptor Supplies offers a variety of these drum lifters for use with overhead hoist, cranes and forklift attachments.

| Style | Model | Capacity | Depth | Drum Type | Height | Width | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|

| A | DRUM-LT-SS | €10,698.92 | RFQ | |||||

| B | DL-1000-SS | €988.18 | RFQ |

Ergomatic Counter Balanced Drum Handlers

| Style | Model | |

|---|---|---|

| A | ERGO 650-CB-ML | RFQ |

| B | ERGO 650-CB-PL | RFQ |

| C | ERGO 650-CB-ML-HR | RFQ |

| D | ERGO 650-CB-PL-HR | RFQ |

Drum Lifters

Drum handling equipment like barrel lifters are used for moving around different-sized drums without entailing any physical strain to the user. The most basic kind in this product category is the crane / hoist / overhead drum lifters, used in conjunction with cranes, to lift and transport heavy drums by grabbing the upper rim. The portable or forklift drum lifters can be simply strapped onto the portable truck, without grabbing the rims. These forklift barrel lifters have automated hydraulic controls for minimising user fatigue while loading / unloading.

- Drum Handling Safety Tips: Heavy drums should be handled with proper drum handling equipment, like below-hook drum lifters, drum trucks or forklift attachments.

- Conditions such as uneven or slippery floors and restricted spaces can entail greater risks. Plastic and fibre drums should be handled with utmost care in such situations.

- One should be extremely careful when using a forklift. The blades on the forklift can easily pierce through the drum and can cause spillage.

Uses

Drum lifters are widely used for handling steel, plastic and fibre drums in food & packaging, recycling, material handling, marine, chemical and pharmaceutical industries.

Features

- Morse Drum overhead crane lifters are meant for transporting the drum in an upright position.

- They feature a built-in plate that supports the drum and load binders for securing the drum in position.

- These drum lifters come integrated with fork pockets and fork mount hooks to be attached with a monorail, crane or chain block for moving the drums.

- Their heavy-duty steel / stainless-steel construction protects the drum lifter against weathering damages.

Justrite overhead drum lifters feature tong-style design for lifting heavy drums by simply gripping the drum chime. These rugged lifters resist accidental opening / bending under heavy loads.

- Portable drum lifters are suitable for applications that require the user to lift and rotate the drum to safely dispense into containers.

- They feature compact base for a small footprint and manoeuvrability in confined spaces with a tight turning radius.

- These drum lifters can easily accommodate steel, plastic & fibre drums and rotate them up to 360 degrees.

- Some models also include a built-in scale indicator for weighing the drum weight with accuracy while dispensing the material.

Drum stackers from Dayton & Vestil are designed for lifting & stacking heavy drums in commercial warehouses. The hydraulic lifting mechanism of these lifters prevents them from losing balance (even mid-transit) and facilitate fatigue-free drum stacking in heavy workload environments.

Valley Craft drum loaders feature three-wheel design with a rear-mount swivel caster for maximum manoeuvrability in tight spaces. These drum loaders are further integrated with a brake for preventing unwanted movement.

Working Mechanism

The overhead drum lifters are easy & safe to operate in contrast to traditional lifting equipment. These lifters are used in conjunction with overhead cranes and a chain to hold & lift the drum using the rim. The directional flexibility of the drum depends upon the crane movement and can be easily repositioned / relocated / detached by unlocking the drum lifter's locking mechanism.If the requirement is to lift & transport drums with or without the upper rim, portable drum lifters are an ideal choice. These hydraulic drum lifters feature swivel casters for reducing the frictional losses on factory floors. They can also tilt / rotate the drum, allowing the inner content to flow easily.

Standards and Approvals

The drum lifters provided by Dayton, Eagle, Enpac, Grainger, Justrite, Morse Drum, Vestil, Valley Craft and Wesco meet OSHA industry standards for user safety.

Features

Morse Drum Overhead Crane Lifters:

- They feature a built-in plate that supports the drum and load binders for securing the drum in position.

- These drum lifters come integrated with fork pockets and fork mount hooks to be attached to a monorail, crane or chain block for moving the drums.

- Their heavy-duty steel / stainless-steel construction protects them against weathering damages.

Justrite Overhead Drum Lifters:

- They feature a tong-style design for lifting heavy drums.

- These portable drum lifters are suitable for applications that require the user to lift and rotate the drum to safely dispense into containers.

- They feature a compact base for a small footprint and manoeuvrability in confined spaces with a tight turning radius.

- These drum lifters can easily accommodate steel, plastic & fibre drums and rotate them up to 360 degrees.

Frequently Asked Questions

Can drum lifters be used for both horizontal and vertical orientation?

Some drum lifters can be used in both horizontal and vertical orientations. These lifters are also called 'bi-directional' drum lifters having a pivot or hinge mechanism that allows them to easily convert the orientation from horizontal to vertical and vice versa, allowing great versatility in different lifting and transporting applications.

Are there manual or electric drum lifters?

Yes, oth manual and electric drum lifters are available for different industrial applications. Manual drum lifters are operated by using a hand crank or lever to lift and transport drums. On the other hand, electric drum lifters are powered by an electric motor and operated by a control panel or remote control. They lift and transport drums with minimal physical effort, making them more ergonomic for continuous use.

Do I need any special training to use a drum lifter?

- It is recommended that operators receive proper training before using a drum lifter. Proper training should cover the following topics:

- Safety: Operators should be made aware of the potential hazards associated with drum lifters, such as falls or chemical spills.

- Operating procedures: Users should be familiar with the proper procedures for operating drum lifters. This includes basics like how to attach and detach the lifter from the drum, how to properly transport the drum and how to safely secure the drum in place.

- Weight limits: Operators must be familiar with the weight limits of the drum lifter to prevent any mishappening.

- Use of PPT kits: Users should know appropriate personal protective equipment when operating the lifter, including hats, safety glasses and steel-toed boots.

- Inspection & Maintenance: Users must be familiar with inspection & maintenance procedures. This includes checking for wear & tear, lubrication / relubrication of moving parts and troubleshooting problems.

Which safety features are important in a drum lifter rotator?

Safety features include locking mechanisms to secure drums during rotation, load capacity indicators and emergency stop buttons to ensure safe drum handling.

How do you operate a hydraulic drum lifter?

To operate a hydraulic drum lifter, pump the hydraulic handle to raise the drum and a release valve is used to lower it safely.

What are the advantages of using steel drum lifters over other materials?

Steel drum lifters offer durability, resistance to corrosion and the ability to handle heavy steel drums, making them ideal for rugged industrial environments.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- TREGASKISS

- ALL MATERIAL HANDLING

- Moisture Testers

- Ground Rods

- TIG Torches

- Combination Starters

- Thread Turning Tools

- HARRIS Regulator Mounting Station

- BALDOR MOTOR Close Coupled Pump Motors, JM Type, Open Drip Proof, Single Phase

- BANJO T Handle

- BANJO Elbow, 45 Degrees, Polypropylene

- DESTACO 215 Series Horizontal Hold Down Clamps

- ANSELL 87-209 Alphatec Natural Rubber Latex Gloves

- ANSELL 70-225 Hyflex Reversible Cut Resistant Gloves

- OIL SAFE Spill Decks