These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Safety

- Confined Space Equipment

- Confined Space Venturi Blowers

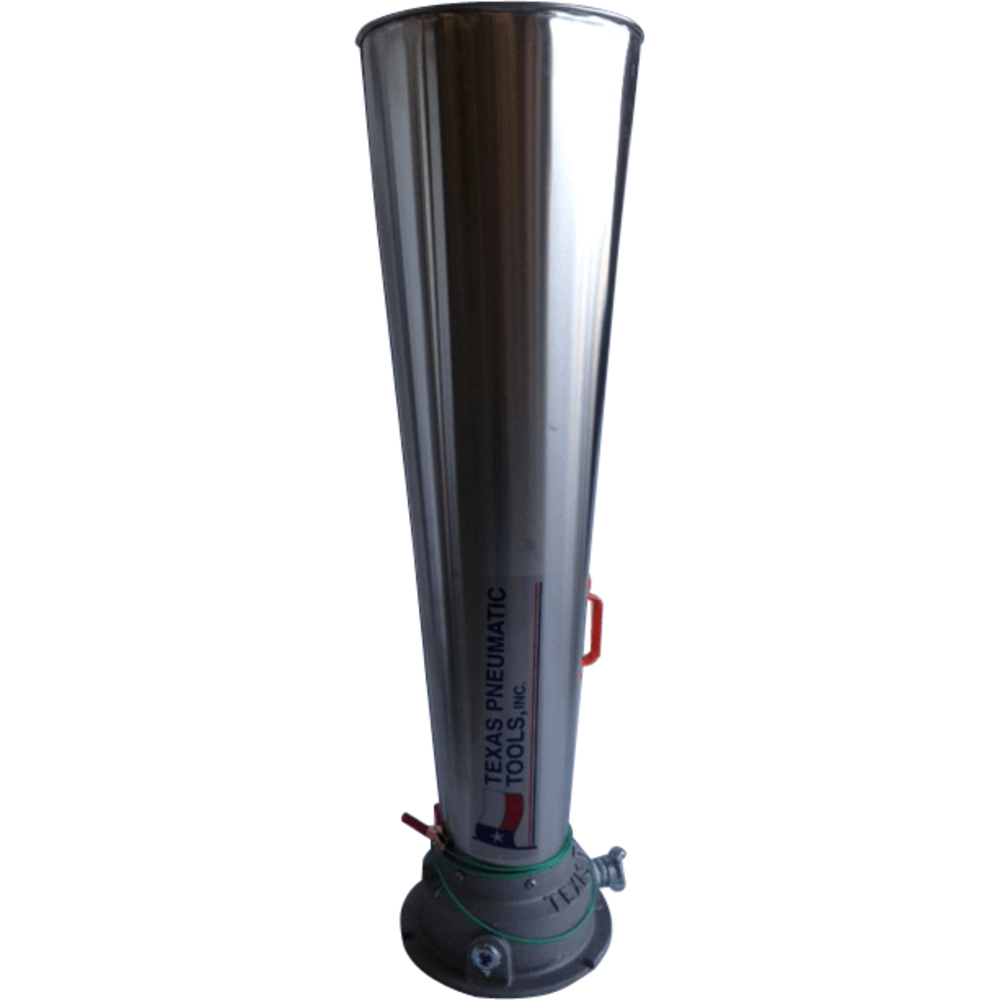

Confined Space Venturi Blowers

Confined space venturi blowers are used for extracting hazardous vapours or ventilating cool spaces in refineries, reservoirs, laboratories, chemical plants and metal fabrication plants.

...Read moreVenturi Cone Blowers

Venturi Air Movers

Texas Pneumatic Tools air movers are designed to blow air into confined spaces for dispensing fumes / cooling machinery in hazardous areas, refineries, chemical plants & shipyards. These air movers have no moving parts which reduce the maintenance downtime and feature a steel horn to keep the working personnel cool under elevated temperature. They provide ground wire connection for minimising the risk of static sparks in volatile environments. Choose from a wide range of these Texas Pneumatic Tools air movers, available in variants delivering airflow ranging from 815 to 7304 cfm on Raptor Supplies.

Texas Pneumatic Tools air movers are designed to blow air into confined spaces for dispensing fumes / cooling machinery in hazardous areas, refineries, chemical plants & shipyards. These air movers have no moving parts which reduce the maintenance downtime and feature a steel horn to keep the working personnel cool under elevated temperature. They provide ground wire connection for minimising the risk of static sparks in volatile environments. Choose from a wide range of these Texas Pneumatic Tools air movers, available in variants delivering airflow ranging from 815 to 7304 cfm on Raptor Supplies.

| Style | Model | Material | Bolt Circle Dia. | Air Flow Rate | Air Pressure | Inside Dia. | Overall Length | Slot Dia. | Outside Dia. | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | TX-6AM-SB-P | €1,677.06 | |||||||||

| B | TX-10AM-NP | €2,096.33 | |||||||||

| A | TX-6AM-NP | €943.35 | |||||||||

| C | TX-10AM-P | €1,519.84 | |||||||||

| D | TX-8AM-P | €967.13 | |||||||||

| E | TX-3AM-P | €513.60 | |||||||||

| F | TX-3AMS-P | €466.43 | |||||||||

| A | TX-6AM-P | €597.19 | |||||||||

| G | TX-6AM-SS | €1,729.47 | |||||||||

| H | TX-10AM-SH | €1,991.51 | |||||||||

| I | TX-8AM-SH | €1,467.43 | |||||||||

| J | TX-3AM-SH | €707.51 | |||||||||

| K | TX-3AMS-SH | €701.89 | |||||||||

| L | TX-6AM-SH | €982.65 | |||||||||

| M | TX-10AM | €1,519.84 | |||||||||

| I | TX-8AM | €1,096.08 | |||||||||

| N | TX-6AM | €597.19 | |||||||||

| O | TX-6AMS | €639.38 | |||||||||

| P | TX-3AMS | €438.64 | |||||||||

| Q | TX-3AM | €513.60 | |||||||||

| R | TX-2AM | €482.15 | RFQ | ||||||||

| S | TX-9AMB | €1,358.87 |

Venturi Blowers

Confined Space Venturi Blowers

Confined space venturi blowers are used for extracting hazardous vapours or ventilating cool spaces in reservoirs, refineries, chemical plants, laboratories and metal fabrication plants. Raptor Supplies offers a range of confined space venturi blowers from Air Systems International, Texas Pneumatic Tools and Allegro. Confined space venturi blowers by Air Systems International are designed for the extraction of hazardous gases produced in underground tanks. These blowers feature galvanised steel housing with cast aluminum base to ensure resistance against corrosion and UV radiations. Providing 1/2 & 1 inch NPT connections, these blowers are capable of withstanding pressure up to 140 psi. Allegro confined space venturi blowers feature lightweight construction and plastic / steel housing to provide excellent adhesivity and corrosion resistance. These venturi blowers are equipped with convenient carry handles and can handle pressure up to 140 psi. These confined space venturi blowers are available in plastic, steel and galvanised steel housing variants.

Working Mechanism

- Air Intake: The Venturi blower draws in ambient air from the surrounding environment through its inlet, designed to optimize airflow and efficiently capture air for ventilation purposes.

- Venturi Effect: Incorporating a Venturi tube, the blower utilises a constricted section of the air passage. As air passes through this constricted section, its velocity increases, resulting in a decrease in pressure and creating a vacuum effect.

- Airflow Acceleration: The high-velocity air stream enters the Venturi chamber, where it further accelerates. This acceleration occurs due to the pressure difference between the constricted section and the wider chamber.

- Air Discharge: The accelerated airflow is expelled through the blower's outlet or discharge vent, often equipped with a duct adapter or flexible ducting, directing the airflow to the desired location or connecting with ventilation systems.

- Pressure Generation: The Venturi effect and the resulting airflow generate a pressure differential within the blower, aiding in generating the necessary airflow for effective ventilation.

- Increased Air Circulation: Through continuous intake of fresh air and expulsion at higher velocity and pressure, the Venturi blower promotes air circulation and ventilation within the intended space.

- Performance Control: The blower's performance can be regulated by adjusting the airflow rate using techniques like regulating the inlet size or employing adjustable dampers or control devices.

Features

Air System International Venturi Blowers:

- Air System International venturi blowers feature a base made of cast aluminium for a rigid and durable foundation, ensuring strength and longevity.

- They have galvanised steel housing for excellent strength and resisting corrosion.

- These venturi blowers have a maximum inlet pressure of 140 psi, enabling efficient air movement and ventilation.

Allegro Venturi Blowers:

- Allegro Safety venturi blowers feature linear low-density polyethylene (LLDPE) construction for resisting impact and corrosion.

- These blowers come integrated with a convenient carry handle, allowing easy transportation.

- They are capable of handling steam pressure up to 140 psi and can withstand temperatures up to 220 degrees F.

Texas Pneumatic Tools Venturi Air Movers:

- Texas Pneumatic tools venturi air movers feature a steel horn to keep the working personnel cool under elevated temperatures.

- They provide ground wire connections to reduce the risk of static sparks in volatile environments.

- The brand's TX-6AM-SS features stainless steel horn and base for corrosion resistance and durability.

- These venturi air movers are capable of delivering airflow ranging between 815 and 7304 cfm.

Frequently Asked Questions

What are some precautions that one must take while using Venturi air blowers?

- To ensure compliance with Federal, State and Local laws, proper ventilation procedures should be followed.

- Follow ANSI / API 2015 and 2016 procedures for work in hazardous locations. Electric grounds or static grounds are attached to the bases of all blowers.

- When using an air blower in a volatile atmosphere, the user should always connect a ground wire to discharge static electricity and prevent build-up.

- Make sure that the aluminium base is not dragged along the surface of the steel tank.

- Periodic cleaning with a steam cleaner is the most effective way to prevent nozzle jets from clogging.

- Be sure to secure the air blower in place before turning on the air supply, otherwise, it will move around.

- Before ventilating confined spaces, always check for hazardous gases and sufficient oxygen with a calibrated multi-gas monitor.

- Always have the right respiratory equipment for ventilated workspaces and emergency rescue,.

- Always wear sturdy and snug-fitting clothing. Never wear loose clothing or anything that could get caught on controls or moving parts.

How do I choose the correct blower to ventilate an area?

The user must determine the total volume (in cu.ft) of the space to be ventilated. It is recommended to use a blower capable of delivering 20 exchanges of air per hour. You can screen your requirements on our site, using filters, to narrow down your choices for easy browsing. You can further connect with our customer representatives for more detailed information and guidance.

What is the different types of ducting available for Venturi blowers?

Ducting for Venturi blowers is offered for both standard and statically conductive environments. Statically conductive ducting is available in five different diameters (8, 12, 16, 20 and 26 inches). The ducting is retractable, has a non-collapsible design and meets ASTM 227 standards.

Can a blower be placed vertically above a manhole?

Yes, if it's supported safely, with adequate ingress / egress, vibration, movement and weight mitigation.

When should a confined space be ventilated?

Unless confined spaces are free from atmospheric hazards, they should be purged and / or ventilated before workers enter, to ensure that acceptable atmospheric levels will be maintained while workers are inside.

How to ensure safety while using Venturi air blowers?

- Always connect a ground wire to discharge static electricity and prevent build-up when working in a volatile atmosphere.

- Avoid dragging the aluminium base along the surface of the steel tank.

- Securely fasten the air blower before turning on the air supply.

- Before ventilating confined spaces, use a calibrated multi-gas monitor to check for hazardous gases and ensure sufficient oxygen levels.

- Ensure appropriate respiratory equipment for ventilated spaces and emergency rescue situations.

- Avoid wearing loose clothing or any items that could become entangled in controls or moving parts.

What do I mantain these confined space venturi blowers?

- Regular Cleaning: Clean the venturi blower regularly to remove dirt, debris and contaminants. Use a soft brush or cloth to gently wipe the exterior surfaces. Avoid abrasive materials that could cause damage.

- Inspect and Clean Air Passages: Check the inlet and outlet air passages for blockages or obstructions. Clear any debris or foreign objects that hinder airflow. Utilise compressed air or a vacuum if needed.

- Check Filters: If your Venturi blower is equipped with filters, regularly inspect them. Clean or replace the filters according to the manufacturer's recommendations to maintain proper airflow and prevent clogging.

- Lubrication: Refer to the manufacturer's guidelines to determine if lubrication is required for your venturi blower. Follow the recommended procedures and intervals for smooth operation.

- Tighten Connections: Periodically inspect and tighten all connections, including hoses, fittings and fasteners. Loose connections can result in air leaks and reduced efficiency.

- Check Motor and Electrical Components: Examine the motor for signs of wear or damage. Ensure that all electrical components are proper and in good condition. Consult a qualified technician for repair or replacement if necessary.

- Follow Manufacturer's Guidelines: Always adhere to the manufacturer's specific maintenance instructions for your venturi blower. They may provide additional recommendations or procedures tailored to your specific model.

How to prevent clogging?

- Regular Maintenance: Perform regular maintenance on the Venturi blower, following the manufacturer's guidelines, to keep it clean and free from debris.

- Proper Filtration: Use suitable filtration systems or filters to prevent debris, dust, and particles from entering the blower, reducing the chances of clogging.

- Avoid Excessive Particulate Exposure: Minimise the blower's exposure to excessive amounts of particulate matter, like dust or fine particles, which can lead to clogging. Implement measures to control and minimise particulate generation in the surrounding environment.

- Regular Inspections: Routinely inspect the blower's inlet and outlet areas for signs of obstruction or blockages. Promptly remove any accumulated debris or foreign objects.

- Proper Ventilation System Usage: Ensure that the venturi blower is appropriately sized and matched with the ventilation system. Proper airflow and pressure management can decrease the risk of clogging.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- SHARKBITE

- CCEALIGHTS

- LAMONS

- Rivet Nuts

- Elbow Knee and Ankle Supports

- Fuel Transfer Pumps w/Nozzle

- Glass and Ceramic Drill Bits

- Relief Valves

- SUPERIOR TOOL Tube Cutters

- LEGRIS Union Ys

- E JAMES & CO Rubber Sheet, General Purpose, 50A

- EATON NRX Series Adapter Kits

- AKRO-MILS 30088 Shelfmax Shelf Bins

- JACKSON SAFETY Due North Heavy Duty Industrial Ice Traction Aids-Integrated Spikes

- JOHN GUEST Stem Adapters, NPTF Thread, Acetal Gray

- VIEGA PROPRESS Caps, SS, Press Connection, FKM Seal