These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Pumps

- Centrifugal Pumps

- Chemical-Resistant Pumps

Chemical-Resistant Pumps

Moving mild acidic fluids, chemicals and other corrosive liquids through piping systems can be a difficult process and would require the right pump.

Raptor Supplies offers an entire

1/25 hp Chemical-Resistant Pumps

| Style | Model | Housing Material | Nameplate Voltage | Max. Flow Rate | Max. Head | Max. Flow Rate @ 10 Ft. | Impeller Material | Best Efficiency Head | Max. Flow Rate @ 5 Ft. | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | E10-NSTNDNN1W-19 | €366.69 | |||||||||

| A | E10-NSHNDNN2W-02 | €376.49 | |||||||||

| B | E3-NSHVNN3W-13 | €278.23 | |||||||||

| C | E10-NSHVNN1W-23 | €437.43 |

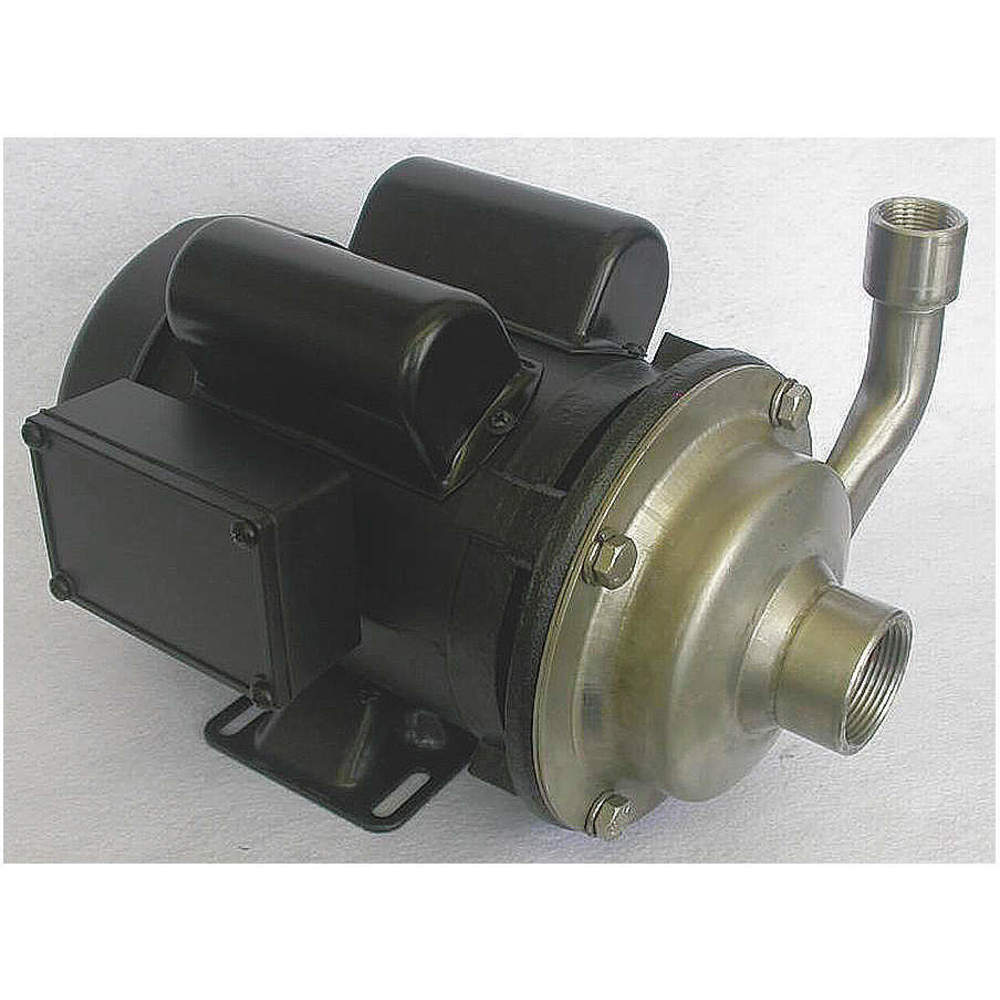

Chemcial Resistant Centrifugal Pumps

Dayton centrifugal pumps are designed for transfer of non-flammable liquids. They are suitable for continuous medium-pressure circulation, jockey pump service, booster service, irrigation and other pumping applications. They come with a water seal flush port for decontamination of chemicals on the seat elastomers and seals. Choose from a range of these centrifugal pumps, available in 1/4 and 1/8 inch maximum diameters on Raptor Supplies.

Dayton centrifugal pumps are designed for transfer of non-flammable liquids. They are suitable for continuous medium-pressure circulation, jockey pump service, booster service, irrigation and other pumping applications. They come with a water seal flush port for decontamination of chemicals on the seat elastomers and seals. Choose from a range of these centrifugal pumps, available in 1/4 and 1/8 inch maximum diameters on Raptor Supplies.

| Style | Model | Hp | Housing Material | Nameplate Voltage | Phase | Max. Flow Rate | Max. Flow Rate @ 15 Ft. | Max. Head | Outlet Size | Price (ex. VAT) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 4JMX5 | €1,211.37 | |||||||||

| B | 4JMX4 | €1,727.21 | |||||||||

| C | 4JMV9 | €1,233.48 | |||||||||

| D | 5WXT7 | €1,880.97 | |||||||||

| E | 4JMW1 | €1,263.28 | |||||||||

| F | 2YER9 | €1,256.02 | |||||||||

| G | 2YEU1 | €1,431.60 | |||||||||

| H | 2YEW3 | €1,555.47 | |||||||||

| I | 2YEW2 | €1,473.72 | |||||||||

| J | 5WXT6 | €1,633.47 | |||||||||

| K | 4JMX2 | €1,174.05 | |||||||||

| L | 4JMX3 | €1,393.09 | |||||||||

| H | 2YEW1 | €1,438.27 | |||||||||

| I | 2YEV9 | €1,384.17 | |||||||||

| M | 4JMV8 | €1,126.21 | |||||||||

| N | 4JMV7 | €1,077.48 | |||||||||

| G | 2YER8 | €1,233.60 | |||||||||

| O | 5WXT5 | €1,645.40 | |||||||||

| F | 2YER7 | €1,182.01 | |||||||||

| P | 5WXT4 | €1,629.54 | |||||||||

| Q | 5WXT1 | €1,069.54 | |||||||||

| R | 5WXT0 | €1,241.66 | |||||||||

| F | 2YER3 | €1,027.25 | |||||||||

| S | 4JMW8 | €1,120.61 | |||||||||

| T | 4JMW7 | €1,108.94 |

Compact Submersible Centrifugal Pump, 1/40 Hp, 115V

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 502303 | AB2VRD | €370.08 |

Compact Submersible Centrifugal Pump, 1/150 Hp

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 526003 | AC2YGN | €230.46 |

Centrifugal Pump, 3 Hp, 145 gpm

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 90210030 | BP7NDK | - | RFQ |

Chemical-Resistant Pumps

What is a chemical resistant pump?

Chemical resistant pumps move mild acidic fluids, chemicals and other corrosive liquids through piping systems. These pumps are available in a variety of housing materials, voltages & horsepower ratings for both agricultural and industrial purposes. Chemical resistant pumps can handle chemicals, chemical slurries & substances with varying levels of viscosity, corrosiveness and abrasiveness.

Chemical dosing pumps are positive displacement pumps that inject a precise dose of chemicals into water, gas or steam. They are typically part of a chemical feed system that comprises a pump (or multiple pumps), a storage tank, pipes and a control panel. There are different methods and types of pumps that can be used, but the general procedure is to draw a preset amount of chemical into a holding container and then inject it into a pipe or tank that holds water or other material to be dosed.

Chemical resistant pumps are ideal for handling a variety of liquids and are suitable for most continuous-duty & high-flow applications in the plumbing, electronics, water treatment and construction industries. Raptor Supplies offers a wide range of these pumps from brands like Dayton, Laing Thermotechand Little Giant. Daytonchemical resistant centrifugal pumps are designed for irrigation, spraying systems, transfer of non-flammable liquids and applications where no suction lift is required. These centrifugal pumps come equipped with a water seal flush port for the decontamination of chemicals on the seal & seat elastomers. All models feature thermal protection to prevent overheating and operate only after cooling down. Centrifugal pumps from Little Giantfeature a single-phase, square flange motor that can operate at speeds up to 3600 rpm, with thermal overload protection for safe operation. These centrifugal pumps come equipped with a glass-filled thermoplastic impeller for increased efficiency and ports providing proper air bleeding to prevent frost damage. These chemical resistant pumps feature a large drain hole and shaft flinger in an adapter bracket to prevent moisture from damaging bearings.

Uses

Chemical resistant pumps can be used in chemical & petrochemical plants, pharmaceutical plants, food & beverage industries, refineries, gas & power plants, water treatment facilities, tank farms, heating & refrigeration systems, etc. They can transfer a host of materials, including hydrochloric acid, sulfuric acid, benzene, nitric acid, hydrofluoric acid, chlorine, bromine, hydrocarbons, aggressive & explosive chemicals, halogenated solutions, high purity chemicals, salt water, waste water, noxious liquids, caustics, heat transfer fluids, ethylene glycol, propylene glycol and recovery solvents.

Features

- Chemical resistant pumps produce high flow rates under moderate head conditions.

- They are designed for transfer of non-flammable liquids, water circulation, booster service, irrigation, spraying systems, jockey pump service, aggressive liquid applications, and applications where no suction lift is required.

- Selected models have a water seal flush port that allows the decontamination of chemicals on the seal and seat elastomers.

- These pumps feature compact construction to provide ease of installation.

- They are available in 1 & 3 phase configurations and power ranging from 1 to 3 hp, on Raptor Supplies.

Working Mechanism

- Chemical resistant pumps move fluids through a system by using circular pump casing with one or more impellers. Impellers create flow by turning either axially, radially or a mixture of these two.

- Axial flow pumps lift liquid against the shaft of the impeller, essentially like a propeller on a boat. The propelling action of the impeller vanes generates pressure. These pumps are flow dependent, exhibiting low pressure and high flow. In axial flow pumps, the liquid is accelerated through the impeller centre and out along the impeller blades at right angles (radially) to the shaft of the pump. The pump develops pressure entirely through centrifugal force.

- Pumps with mixed flow push liquid at an angle greater than 90 degrees, away from the shaft. The impeller creates pressure partly because of centrifugal force and partly because of lifting action. Using medium flow and medium pressure, mixed flow pumps combine the benefits of axial and radial flow pumps.

Standards and Approvals

Chemical resistant pumps must meet or ASME, ANSI, API or NACE standards before they can be used for boiler, pressure vessel, oil & gas refinery, nuclear or other mission critical applications.

Frequently Asked Questions

Why should we buy chemical resistant pumps?- Leaks during production can have severe health consequences for plant workers and the surrounding environment.

- Chemicals are expensive to produce, leading to quality concerns and lost revenue if the end product is contaminated during production.

- Equipment for demanding chemical process applications can be extremely expensive and have limited performance life.

The aforementioned reasons are why chemical resistant pumps should be used to transfer harmful substances. These pumps must be capable of handling substances efficiently in order to avoid production shutdown or pump breakdown.

What points must one keep in mind while maintaining the upkeep of chemical resistant pumps?

Under normal circumstances and proper handling procedures, these pumps don't require a lot of maintenance. They are 100% oil-free, meaning you don't have to oil the parts throughout the lifetime. These pumps come with a cylinder and non-lube piston. Even the bearings of the pumps are sealed and lubricated permanently to ensure that users don't have to take the trouble of oiling them.

Leakage and contamination are two reasons why pumps might malfunction. This usually happens due to poor pressure. Pumps must be thoroughly clean in order to operate at maximum efficiency. If the pressure problem still exists, you might have to call a service technician.

What safety points must one keep in mind while using chemical resistant pumps?

- Always use the pump in a dry and well-ventilated area. You should also check if the pump's cooling fan is working correctly. It will cool down the machine whenever needed. It should at least be 1 inch away from a wall or any kind of obstruction.

- Keep the power cord safely when the pump is not in use. It is best to wrap the cord around the pump instead of leaving it as it is.

- Don't forget to inspect the plug, cord or hose for signs of damage before using the pump. It is dangerous to use a damaged pump because you will be dealing with chemicals.

- Don't apply oil to any part of the pump because you might end up polluting the air delivery port leading to the air handling equipment. This will only damage the pump instead of making it work smoothly.

What points must one keep in mind before buying a chemical resistant pump?

- Before selecting a chemical pump, you need to have a solid grasp of the application requirements and chemical media properties, as well as the performance and size specifications to perform the task.

- The base material of a chemical pump is important to consider, as it affects the type of media that can be handled effectively. System fluids may be abrasive, acidic, caustic, tacky, very hot, very cold, or otherwise hazardous. Base materials such as cast iron, plastic and stainless steel possess different advantages for handling different types of materials.

- Plastics and thermoplastics may be the least expensive base materials and provide excellent corrosion resistance from acids and various chemicals.

- Stainless steel alloys provide protection against chemical & rust corrosion and have higher pressure ratings than most plastics.

- Cast iron provides excellent strength and abrasion resistance, in addition to high pressure ratings.

- The primary performance specifications to consider include flow rate, head, pressure, horsepower & operating temperature.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- BEVERAGE-AIR

- VALVOLINE

- BURRELL SCIENTIFIC

- Yoke Ends

- Vehicle Stands

- Drain Cleaning Accessories

- Magnetic Starters with Thermal Overload

- Keychain and Mini Flashlights

- MAIN FILTER INC. Interchange Hydraulic Pressure Line Filters, Wire Mesh, 149 Micron, Viton Seal

- REGAL End Mills, Single End, 4 Flutes, HSS, CC, TiALN

- GROVE GEAR GRG Series, BMQ-R Style, 821 Size, Ironman Worm Gear Reducers

- IRON HORSE Worm Gearbox Output Covers, Stainless Steel

- DWYER INSTRUMENTS BTM3 Series Maximum/Minimum Bimetal Thermometers

- ALLPAX 6000 Series Heavy Duty Gasket Cutter Kits With Cutting Board