These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Power Tools

- Finishing Tools

- Belt/Disc Sanders

Belt/Disc Sanders

If you are employed in the woodworking industry or enjoy woodworking, then a sander is an essential tool for you. Sanding machines perform three general functions: shaping, smoothing and

...Read moreBenchtop Belt And Disc Machines

Belt/Disc Sanders

Belt Grinders

Grinders

Oscillating Edge Sanders

Belt/Disc Finishing Machines

Disc Sanders

Disc Sanders

Disc Abrasive Finishing Machines

Edge Banders

Belt/Disc Sanders

Belt Sanders

Disc Sanders

Belt And Disc Finishing Machines

Belt Grinders

Belt Finishing Machines

Combination Belt And Disc Finishing Machines

Belt Grinders, 120 / 240V, 7 / 3.5A

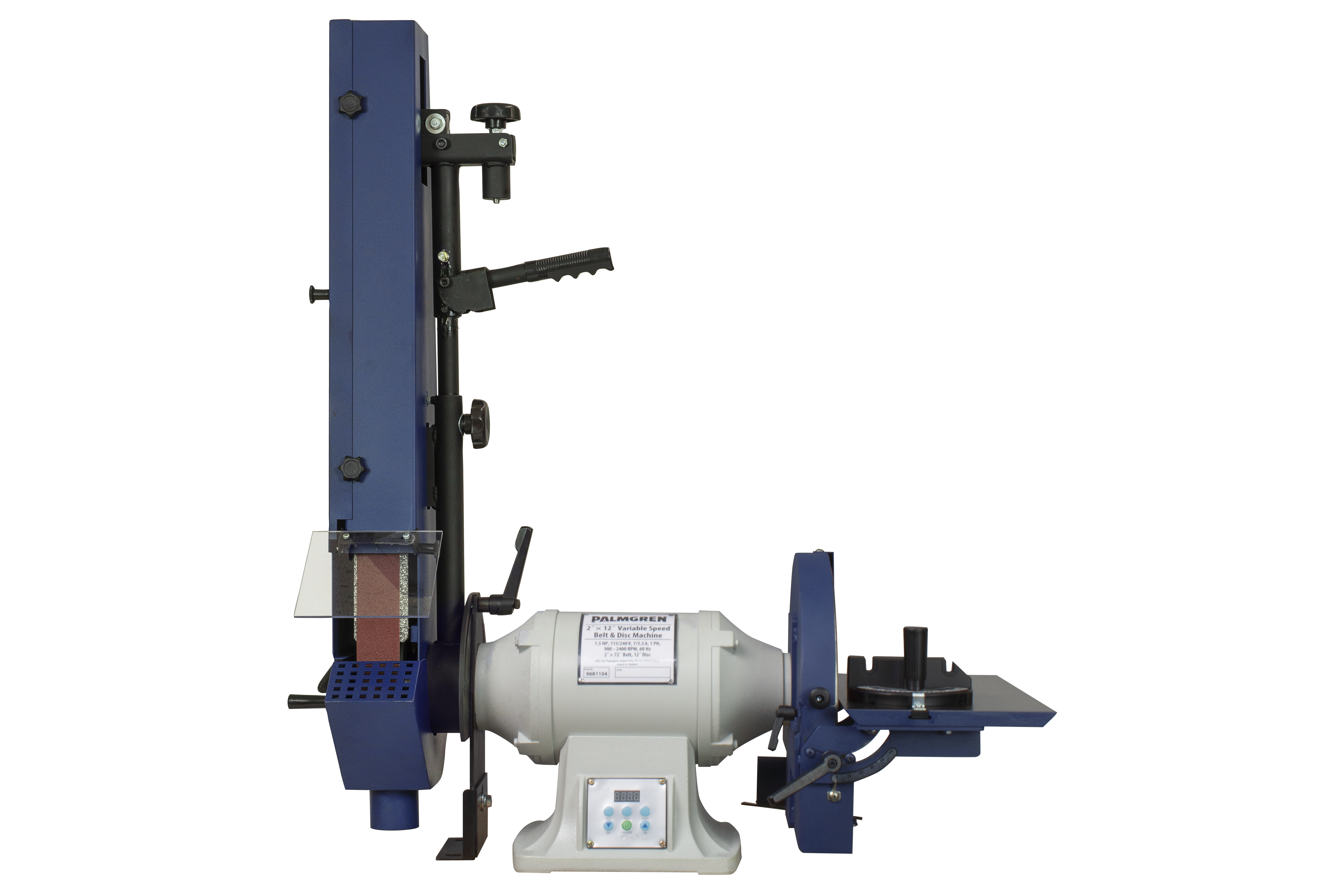

Dayton belt grinders are ideal for grinding, sanding, deburring and contouring. These grinders feature a powerful capacitor motor for all-day use and allow adjustment of belts in both horizontal & vertical directions. They are integrated with a front mounted On/Off paddle switch to turn them On/Off automatically and full belt guards for added safety. Variants are available in heights of 21 and 26 inches.

Dayton belt grinders are ideal for grinding, sanding, deburring and contouring. These grinders feature a powerful capacitor motor for all-day use and allow adjustment of belts in both horizontal & vertical directions. They are integrated with a front mounted On/Off paddle switch to turn them On/Off automatically and full belt guards for added safety. Variants are available in heights of 21 and 26 inches.

Belt/Disc Sanders

What are belt / disc sanders?

Belt / disc sanders are versatile power tools that are more efficient for two types of tasks. The disc section is suitable for precision edge work and the belt section is suitable for flattening faces & edges, shaping contours and smoothening inside curves. The main purpose of belt and disc sanders is to remove material from wood stock. They are the perfect option for sanding flat wooden surfaces.

These belt / disc sanders quickly produce curves on stock edges, with the length of the curve depending on the belt width. They are useful for rounding corners & edges, especially the edges of long boards along the grain. Bench sanders are helpful in smoothing oddly shaped wooden surfaces.

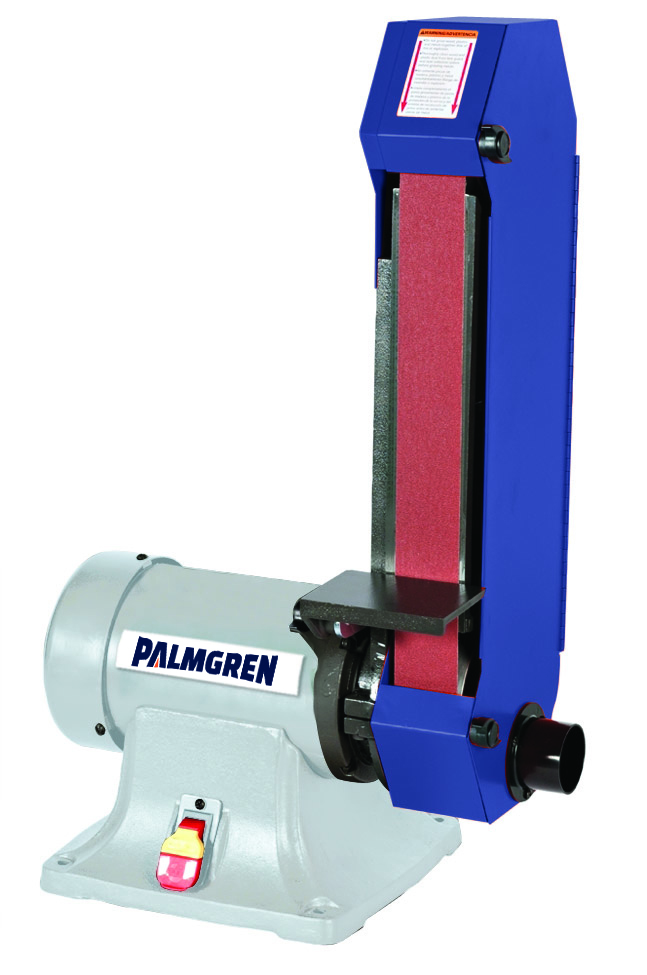

Raptor Supplies offers combination belt / disc sanders & grinders that are used for sanding, grinding, deburring & contouring, from brands such as Dayton, Dake Corporation, Dynabrade, Jet Tools, Powermatic, Palmgren and Slugger. These disc and belt sanders are used on wood and generally operate at higher speeds than grinders, which are used with metal workpieces. These benchtop tools feature a round & flat surface used to shape & finish metal, and have a belt for shaping and finishing wood, plastic & composites. They are available in disc diameters ranging from 3 to 24 inches. These belt / disc sanders & grinders come in one and three phase configurations for voltage ratings ranging between 115 and 460V. These sanders have cast iron construction and feature a deluxe mitre gauge that turns & locks so that angles are set with accuracy. They have a power take off mechanism that allows mounting of an optional flex shaft for carving, drum sanding and deburring. They come with a removable plate to allow sanding, grinding or finishing of outside curves or oddly shaped workpieces on the belt.

For stainless steel machining, smoothing over burrs on metal, chamfering edges for welding and cleaning up casting, we offer bench belt, linear, pedestal belt, three wheel and versatility grinders powered by 1 to 5 phase motors. Choose from a wide range of grinders, tube / pipe polishing modules and belt finishing machines on Raptor Supplies.

Uses

Belt sanders are multipurpose tools. They can be used for trimming, sanding very rough surfaces, levelling (like a replacement board in a hardwood floor), and freehand sizing & shaping.

Features

- Belt / disc sanders have a quick release tension mechanism that makes belt changes quick and easy for precise edge work, like fitting mitre joints.

- They grind, sand, polish and contour sand, metal, wood, plastic & composite materials.

- These units have a flat belt that helps the operator to utilise both fence guards to allow your stock to be flat against the abrasive paper.

- The edges on belts and discs act like cutting tools if contact is made with them.

- Models with dust collection shrouds on the belt and disc are also available.

- Selected models come with an enclosed base that protects the motor from dust and debris.

- These units offer a simplified design that eliminates belt tension rollers, in order to reduce maintenance costs.

- They enable the operator to finish the workpiece on belt slack in a variety of positions, for optimum efficiency.

- Using Dynabrade 64861 three wheel grinders, you can adjust the abrasive belt tracking system linearly using a conventional tracking system.

Working Mechanism

How do you use belt / disc sanders"

In order to begin the sanding process, you simply need to follow these steps:

- Place the piece of wood on the sander.

- Securely hold your workpiece.

- Don't push down on the sander; let its weight do the work. Go slowly, overlap passes and allow the tool to go past the end without dipping. Be careful not to tip the sander or change speed or direction. Put the cord over your shoulder so it's out of the way.

- Finally, let the sander do the work.

Some tips to keep in mind for the safe operation of the sander:

- The switch must be off before the sander is plugged in.

- Keep the electrical cord at a safe distance from both yourelf and the sander.

- The operating controls must be in proper working condition.

- The abrasive paper must not be worn and should be securely attached to the machine.

- Sanders must be kept clean at all times.

- When not in use, unplug the electrical cord.

Standards and Approvals

Belt / disc sanders are constructed in accordance with UL standards to deliver optimum performance while ensuring utmost safety.

Frequently Asked Questions

What safety tips does one need to keep in mind before using a belt & disc sander?

Precautions to consider while using belt and disc sanders:- Use eye protection to prevent injuries from woodstock kickback or sawdust that flies off the surface.

- Most machines produce high levels of noise and a continuous hum can be uncomfortable and damaging to ears. It is better to use hearing protection while operating a disc or belt sander.

- Use caution while handling workpieces secured to tools. Keep your fingers away from the sandpaper which might rip off your skin within an instant.

- Avoid wearing loose fitting clothes as they can get caught in spinning drums while working.

- If possible, start sanding with grain as it helps prevent wood from slipping off the belt while in motion. Always sand in a downward position and avoid upward movement for better control.

- Proper operation and maintenance of dust collection equipment is essential for effective dust minimisation.

- Workpieces must be large enough to be held while keeping body parts away from moving abrasives.

How to clean up a disc / belt sander?

- Disassemble any fixtures, clamps, etc used in the sanding operation. Return all parts to their proper locations.

- Disconnect the dust collection hose and return the sander to its original location.

- Clean up the area. You can use a shop vacuum to clean up any additional sawdust.

What is the difference between a disc and belt sander?

Belt sanders are much bigger in size than bobbin & disc sanders. Its long, flat surface makes it ideal for flattening and levelling long pieces of timber, such as panelled doors.

How to maintain belt / disc sanders?

First, make sure that the belt is oriented properly. Some belts have a preferred direction, indicated by an arrow on the inside. Non-directional belts can be installed either way. The operator will have to adjust the tracking to keep the belt centred on the roller. Hold the sander up, turn it on, and see if the belt either rubs against the housing or starts working its way off the rollers. With the trigger on, adjust the tracking knob until the belt is centred on the rollers. You might have to make a slight adjustment when the sander is on the wood. Some sanders have variable speeds. You can go at the maximum speed most of the time, but you'll want to throttle it back for delicate work.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- HALSEY TAYLOR

- GAM WEB

- CS JOHNSON

- Double-Sided Tapes

- Roof Ventilator Accessories

- Refrigerator/Freezer/Ice Maker Acc

- Stainless Steel Foil Rolls

- Labware Washers

- IRONCLAD Cold Condition Waterproof Gloves

- TAPCO Sign Post, Galvanized Steel

- 3M Sanding Belt, 132 Inch X 4 Inch

- REGAL End Mills, Single End, 6 Flutes, HSS, CC, Tin

- APPROVED VENDOR Sanding Finger Sheet

- JOHN GUEST Swivel Male Branch Tees, NPTF Thread, Acetal Gray

- SALISBURY Class 00 Electrical Insulating Rubber Gloves, 11 Inch, Yellow

- STARRETT 711 Series Last Word Dial Test Indicators with Cases

- MEMPHIS GLOVE Cut Pro PU Work Gloves

- ANSELL 11-518V Hyflex Cut Resistant Gloves