These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

- Test Instruments

- Asphalt Testing

- Asphalt Testing Compression Machines

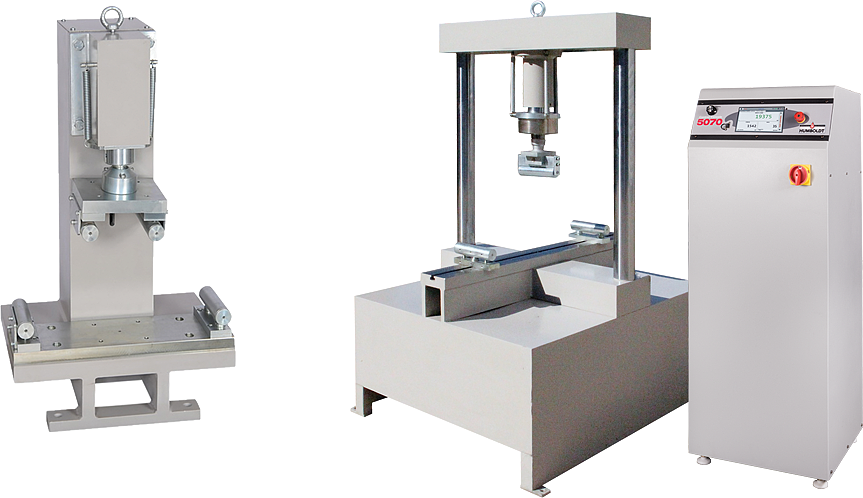

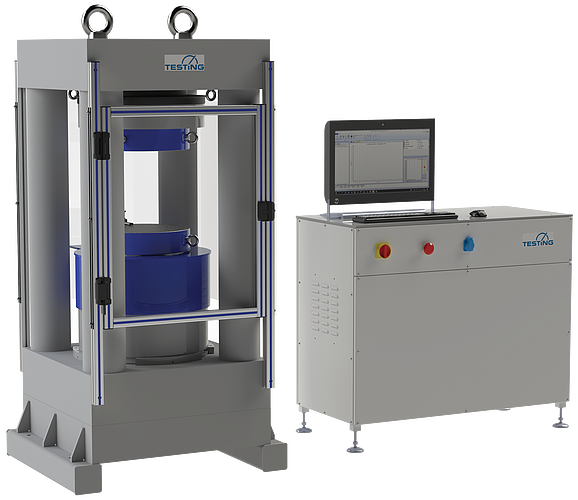

Asphalt Testing Compression Machines

Asphalt testing compression machines are ideal for testing asphalt samples for their strength, stability & durability. They are used in construction applications for checking if paving

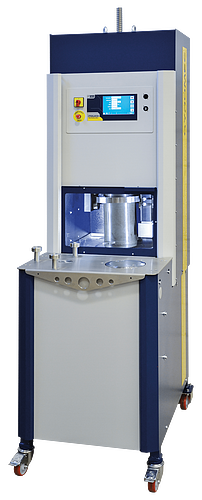

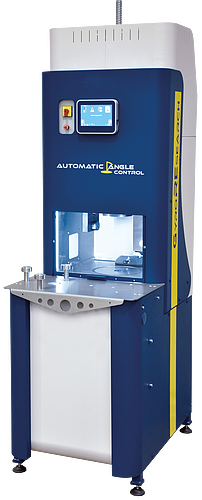

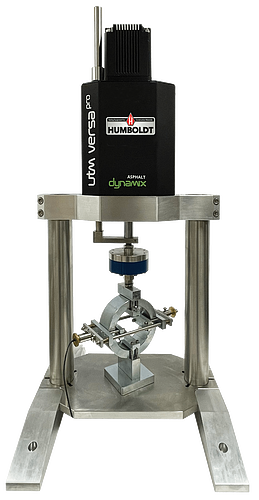

...Read moreGyratory Compactors

| Style | Model | MPN | |

|---|---|---|---|

| A | HA-5000A.4F | RFQ | |

| B | HA-5951.4F | RFQ | |

| C | HA-5952.4F | RFQ |

HCM-1000 Series Compression Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-1000 | RFQ | |

| A | HCM-1000i7 | RFQ | |

| A | HCM-1000i7.2F | RFQ | |

| A | HCM-1000i7.5F | RFQ | |

| A | HCM-1000iH | RFQ | |

| A | HCM-1000iH.2F | RFQ | |

| A | HCM-1000iH.5F | RFQ | |

| B | HCM-1000iHA | RFQ | |

| B | HCM-1000iHA.4F | RFQ | |

| B | HCM-1000iHAC | RFQ | |

| B | HCM-1000iHAC.4F | RFQ |

HCM-2500 Series Compression Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-2500 | RFQ | |

| A | HCM-2500i7 | RFQ | |

| A | HCM-2500i7.2F | RFQ | |

| A | HCM-2500i7.5F | RFQ | |

| A | HCM-2500i7P | RFQ | |

| A | HCM-2500i7P.2F | RFQ | |

| A | HCM-2500i7P.5F | RFQ | |

| A | HCM-2500iH | RFQ | |

| A | HCM-2500iH.2F | RFQ | |

| A | HCM-2500iH.5F | RFQ | |

| B | HCM-2500iHA | RFQ | |

| B | HCM-2500iHA.4F | RFQ | |

| B | HCM-2500iHAC | RFQ | |

| B | HCM-2500iHAC.4F | RFQ | |

| A | HCM-2500iHP | RFQ | |

| A | HCM-2500iHP.2F | RFQ | |

| A | HCM-2500iHP.5F | RFQ |

HCM-3000 Series Compression Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-3000 | RFQ | |

| A | HCM-3000i7 | RFQ | |

| A | HCM-3000i7.2F | RFQ | |

| A | HCM-3000i7.5F | RFQ | |

| A | HCM-3000i7P | RFQ | |

| A | HCM-3000i7P.2F | RFQ | |

| A | HCM-3000i7P.5F | RFQ | |

| A | HCM-3000iH | RFQ | |

| A | HCM-3000iH.2F | RFQ | |

| A | HCM-3000iH.5F | RFQ | |

| A | HCM-3000iHA | RFQ | |

| B | HCM-3000iHA.4F | RFQ | |

| A | HCM-3000iHAC | RFQ | |

| A | HCM-3000iHAC.4F | RFQ | |

| A | HCM-3000iHP | RFQ | |

| A | HCM-3000iHP.2F | RFQ | |

| A | HCM-3000iHP.5F | RFQ |

HCM-4000 Series Compression Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-4000 | RFQ | |

| A | HCM-4000i7P | RFQ | |

| A | HCM-4000i7P.2F | RFQ | |

| A | HCM-4000i7P.5F | RFQ | |

| B | HCM-4000iHA | RFQ | |

| B | HCM-4000iHA.4F | RFQ | |

| A | HCM-4000iHAC | RFQ | |

| B | HCM-4000iHAC.4F | RFQ | |

| A | HCM-4000iHP | RFQ | |

| A | HCM-4000iHP.2F | RFQ | |

| A | HCM-4000iHP.5F | RFQ |

HCM-5000 Series Compression Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-5000 | RFQ | |

| A | HCM-5000i7P | RFQ | |

| A | HCM-5000i7P.2F | RFQ | |

| A | HCM-5000i7P.5F | RFQ | |

| B | HCM-5000iHA | RFQ | |

| B | HCM-5000iHA.4F | RFQ | |

| B | HCM-5000iHAC | RFQ | |

| B | HCM-5000iHAC.4F | RFQ | |

| A | HCM-5000iHP | RFQ | |

| A | HCM-5000iHP.2F | RFQ | |

| A | HCM-5000iHP.5F | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-3100.7F | RFQ | |

| A | HCM-3101.7F | RFQ | |

| A | HCM-4100.7F | RFQ | |

| A | HCM-5100.7F | RFQ | |

| A | HCM-6100.7F | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | HA-5100.3F | RFQ | |

| A | HA-5101.3F | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | HA-5125.2F | RFQ | |

| A | HA-5126.2F | RFQ | |

| A | HA-5135.2F | RFQ | |

| A | HA-5136.2F | RFQ |

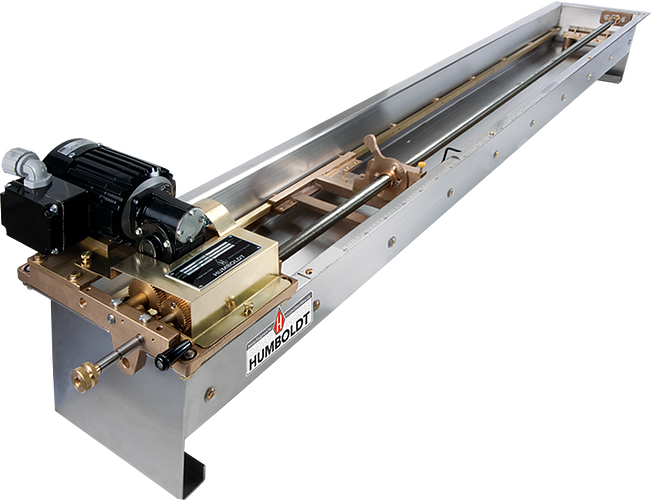

Ductility Testing Machines

| Style | Model | MPN | |

|---|---|---|---|

| A | H-1050 | RFQ | |

| A | H-1050.2F | RFQ | |

| A | H-1050.5F | RFQ | |

| B | H-1068B | RFQ | |

| B | H-1068B.2F | RFQ | |

| B | H-1068B.5F | RFQ | |

| C | H-1068X | RFQ | |

| C | H-1068X.2F | RFQ | |

| C | H-1068X.5F | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | HCM-0030 | RFQ | |

| A | HCM-0030i7 | RFQ | |

| A | HCM-0030i7.2F | RFQ | |

| A | HCM-0030i7.5F | RFQ | |

| A | HCM-0030iH | RFQ | |

| A | HCM-0030iH.2F | RFQ | |

| A | HCM-0030iH.5F | RFQ | |

| A | HCM-0030RT | RFQ |

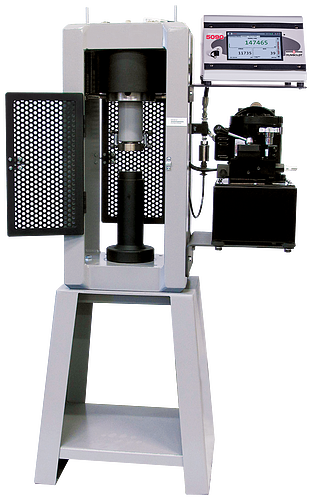

Marshall Compression Machine

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 5DNL3 | AE3JKT | €7,419.42 |

Working Mechanism

- Position the asphalt sample inside an asphalt testing compression machine and secure it according to the manufacturer's instructions.

- Set appropriate load & displacement settings for the machine to conduct the test.

- Switch on the machine and apply the compressive load to the asphalt sample.

- Monitor the machine & the sample during the test. Ensure that the sample does not get damaged or deformed.

- Stop the machine & remove the sample after the test is complete.

- Record the results and the data like the maximum load applied, displacement at failure & other relevant parameters.

- Repeat the testing process for any additional samples.

Frequently Asked Questions

What are some safety guidelines for operating asphalt testing compression machines?

- Wear personal protective equipment like safety glasses, gloves & protective clothing.

- Always follow the manufacturer's instructions.

- Inspect the machine regularly for any damage or defects.

- Use proper lifting techniques to handle an asphalt sample to avoid injury.

- Clean the work area of any debris to prevent accidents.

- Make sure that electrical connections are secure and take caution near moving parts.

How to select an appropriate asphalt testing compression machine?

- Different asphalt testing compression machines perform different types of tests on an asphalt sample. Select a model based on the test to be performed.

- These machines are available in varying capacities. Choose a machine with enough capacity to handle the samples to be tested.

- Choose a machine with proper accuracy for precise and trustable results.

How to maintain these asphalt testing compression machines in operable condition?

- Clean the machine & surrounding area using a soft, dry cloth and a soft-bristled brush.

- Inspect the machine for any loose, damaged or worn-out parts and tighten / replace them if required.

- Ensure appropriate lubricant levels if the machine has a lubrication system.

- Keep the machine calibrated to ensure accurate & precise results.

We are here to help!

Looking for a part not listed here?

Popular Search Queries

Explore More

- KEYSHAFT

- NORDYNE

- Negative Air Machines

- Taper Pins

- Vent Adapters

- ADA Pads

- Box Trucks

- PASS AND SEYMOUR Adorne Series Soft Tap Dimmers

- MARTIN SPROCKET Metric Offset Striking Face Box Wrenches, Black Industrial Finish

- YSI Multi Parameter Meters

- LIFTOMATIC High Volume Forklift Mounted Drum Handlers

- ALLEGRO Blasting Helmet Domes

- WESTWARD Fiberglass Extension Ladders, 300 Lbs.

- ASSOCIATED SPRING RAYMOND TI 250 Gas Springs, Inch

- NORTH BY HONEYWELL NF11X Northflex Nylon Gloves, Red

- ANSELL Coated Nitrile Gloves, Gray White