These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

USA SEALING

Headquartered in Buffalo, New York, USA Sealing manufactures sealing, flow and material technologies for the automotive, aerospace, Oil & gas and more industries. Read More

Filter

Plumbing

Raw Materials

Fasteners

Power Transmission

Pneumatics

Adhesives Sealants and Tape

Security

HVAC and Refrigeration

Welding

Plumbing Filter

About Usa Sealing

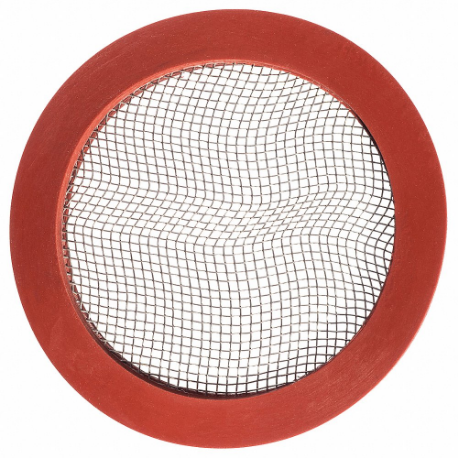

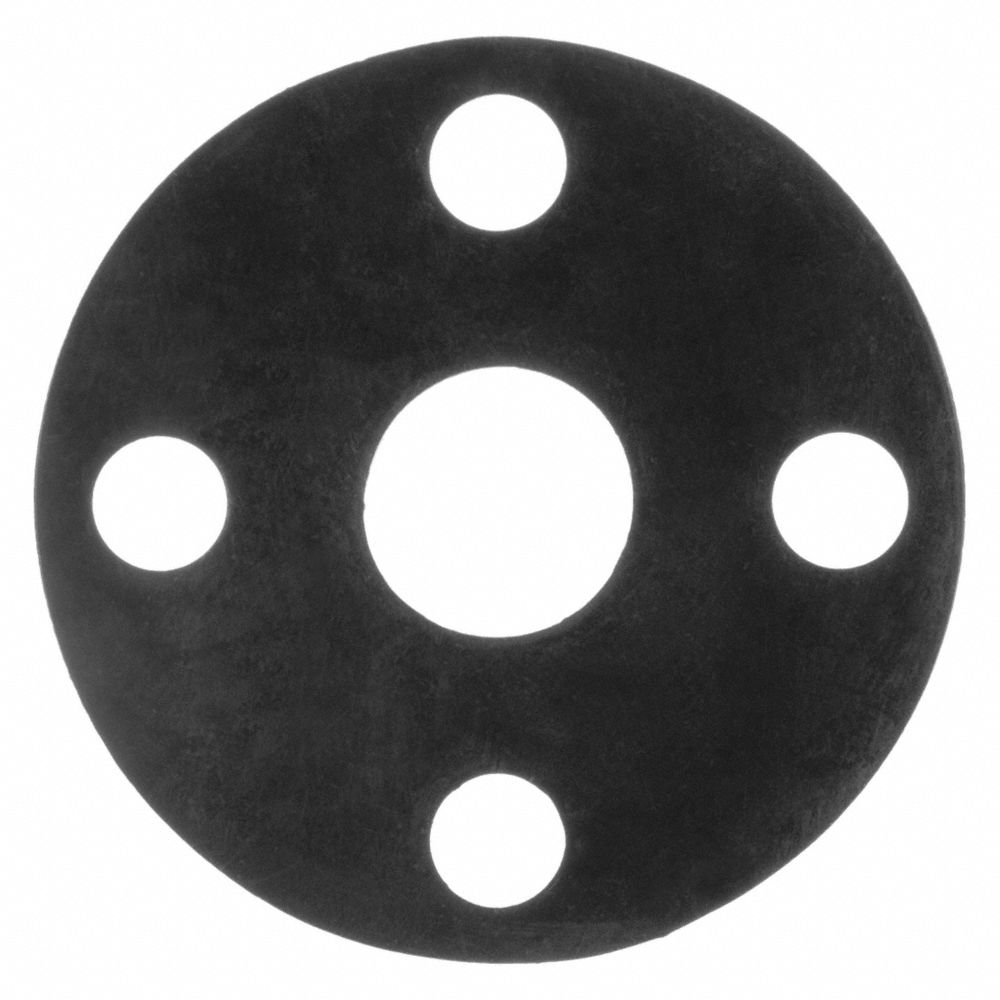

USA Sealing catalogue includes plastic sheets film and flat stock, sheet and ring gaskets, plumbing needle valves, plastic rod stock, plastic tube stock, rubber sheets, hose reel accessories, ball valves and more. USA Sealing ball valves have a 2-piece structure, enhancing durability and reliability in fluid control applications. They come with a blowout-proof stem, providing an added layer of safety and preventing unintended stem removal during operation. These ball valves offer a wide temperature range from -20 to 350 degrees F for stainless steel and 32 to 140 degrees F for acetal construction, making them suitable for diverse industrial settings with varying temperature conditions. The brands linear motion shafts have a minimum surface hardness of 60-65 RC, providing enhanced durability and resistance to wear and abrasion. They come with a shaft diameter of 10 mm, offering compatibility with various linear motion systems. They have a material composition of carbon steel, delivering a balance of strength and machinability, making them suitable for both hardened and non-hardened applications in linear motion systems.

Things to Consider

Cross-Reference Alternatives

Some USA Sealing MPNs cross individual references to the equivalent Vestil, Square D, Morse Drum and Dayton models. So, if you're looking for a competitor item that is either out of stock or obsolete, Raptor Supplies has the equivalent USA Sealing products.

Shipping

These USA Sealing products are small in size. They may require careful packaging as some items might get damaged while shipping. Hence, these USA Sealing products are delivered by air freight for minimum downtime.

Frequently Asked Questions

What advantages do USA Sealing's solid linear shafts offer compared to other options in the market?

USA Sealing's solid linear shafts come with close tolerances for surface finish, roundness, hardness and straightness, making them ideal for moderate to heavy loads using ball bearings. Additionally, their 1060 carbon steel composition ensures durability.

How are the vacuum tube fittings from USA Sealing suitable for fast installations?

USA Sealing's vacuum tube fittings, known as KF or QF fittings, utilise quick-release latches and a centre ring to ensure a secure and leak tight connection, enabling swift assembly and disassembly.

Are the USA Sealing products compliant with any industry standards?

Yes, the 2-way ball valves adhere to ANSI/ASME B1.20.1 standards, and the vacuum tube fittings comply with GB4982-ISO-K standards, ensuring reliability and performance in various applications.