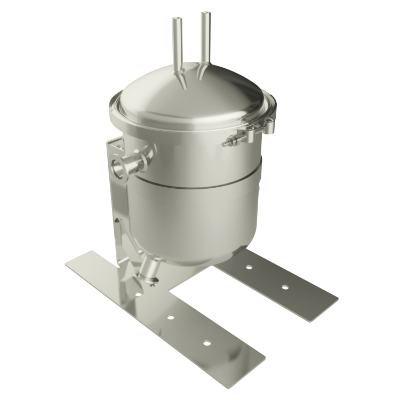

Explosion Protection: ATEX Certified Filters

Explosions can occur in industries such as pharmaceuticals, chemicals, metals, food, plastics, coal & woodworking. Solberg was among the first filtration companies to be certified to service these industries in accordance with the ATEX directive 2014/34/EU (ATEX 114). TUV Rheinland Group has issued RefN 968 / ExAb 557/04 to Solberg. The registration permits the design, manufacture & marking of non-mining inlet filter silencers, inlet filters, inlet vacuum filters, integrated liquid separators / vacuum filters and air / oil separation filters. ATEX certified products are subjected to stringent testing and documentation is available upon request. Most products are suitable for use in Group II, Category 2, Gas Zones 1 & 2; and Group II, Category 2, Dust Zones 21 & 22.