These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

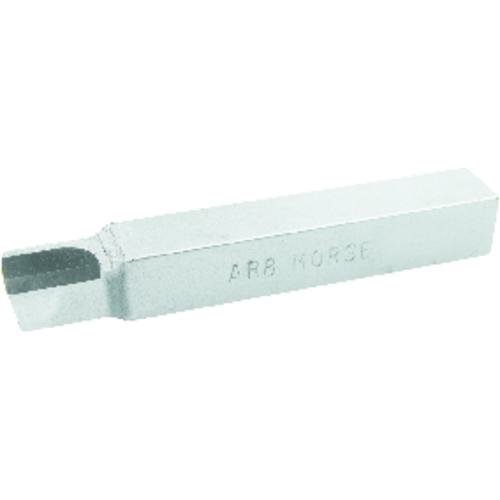

MORSE CUTTING TOOLS

Since 1864, Morse Cutting Tools has been producing precision cutting tools. Headquartered in Novi, Michigan, USA, the brand manufactures jobber length drill bits, taps, high-speed steel end mills, annular cutters and combined drill / countersinks for manufacturing, automotive, aerospace and construction applications. Read More

Filter

Machining

Power Tools

Material Handling

Fasteners

Reference and Learning Supplies

Machining Filter

About Morse Cutting Tools

Morse Cutting Tools catalogue includes a comprehensive line of mills, bits, taps, tools, dies, nuts and counter bores. The brand's 1441 Series drill bits feature an advanced helix geometry, optimising chip evacuation for improved drilling performance. They are equipped with a split-point design, promoting self-centering and reducing the need for a pilot hole, enhancing accuracy and efficiency. Morse Cutting Tools 5989T Series chamfer mills feature an advanced helix geometry, optimising chip evacuation for improved drilling performance. They have a specialised TiAlN coating, enhancing their wear resistance and extending tool life.

Things to Consider

Cross-Reference Alternatives

Some Morse Cutting Tools MPNs cross individual references to the equivalent Westward, Cleveland and Milwaukee models. So, if you're looking for a competitor item that is either out of stock or obsolete, chances are Raptor Supplies has the equivalent Morse Cutting Tools products available.

Shipping

These Morse Cutting Tools products are small in size. They require careful packaging as some items might get damaged while shipping. Hence, these items are delivered by courier shipment and air freight for minimum downtime.

Major Trade Names

SHEARDRILL

SHEARDRILL coolant-through dills are designed to work exceptionally well with a broad range of materials, including carbon steels, cast steels, alloy steels, stainless steels and cast iron, making the...Read more

Ambore Wide Land Flutes

They feature a highly efficient 135-degree self-centring split point for effectively eliminating any walking of the drill bit during initial contact and reducing thrust, resulting in precise drilling....Read more

DRILL-MILL

They are used for drilling, spotting, countersinking, chamfering, slotting, side milling and profile milling. These DRILL-MILLS are constructed with a high-quality cobalt material, offering superior w...Read more

Frequently Asked Questions

Does Raptor Supplies offer guide book / reference book for choosing correct Morse Cutting Tools units?

Yes, it offers the brand's 01650 tap drill chart for choosing the correct units.

What is the difference between a twist drill bit and a centre drill bit?

A twist drill bit is used for general drilling tasks, while a centre drill bit is primarily used for creating a starting point for other drills or for precise centring.

How to extend the lifespan of my taps?

To prolong tap life, use appropriate cutting fluids, maintain proper speeds and feeds, ensure accurate alignment, and perform regular tap maintenance, including cleaning and sharpening.

What safety precautions should I follow when using tools like dies and counterbores?

Always wear appropriate personal protective equipment (PPE), follow safety guidelines for the specific tool and ensure the workpiece is securely clamped to prevent accidents during machining operations.

When should I use a die instead of a tap for threading operations?

Dies are typically used to thread external surfaces like rods or bolts, while taps are used to thread internal surfaces like holes. Choose a die when you need to thread an external surface.