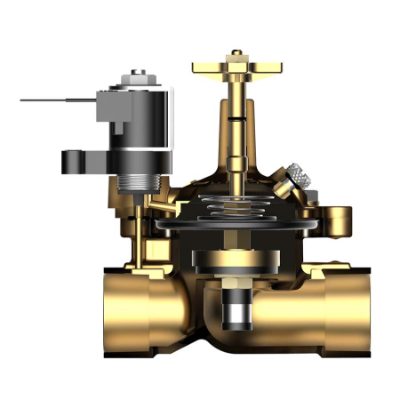

HCR Diaphragm

This patented diaphragm is composed of EPDM with dual layers of chlorine and chloramine-resistant elastomer, designed to outlast the harshest of chemicals typically found in recycled water systems. This two-piece diaphragm comes with a Superior Shield assembly that helps to deflect debris to prevent diaphragm tears.