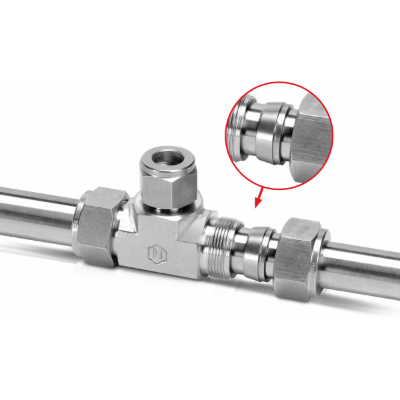

Ham-Let Internet of Things Smart Valves

These valves enable monitoring, control and management of various fluid flow operations remotely. Additionally, their one-piece design minimises the chances of shell leakages. They feature precise differential pressure measurement, safety shut down and motion indication. They have temperature, pressure, vibration, humidity and acoustic sensing features for precisely monitoring & controlling the operation.