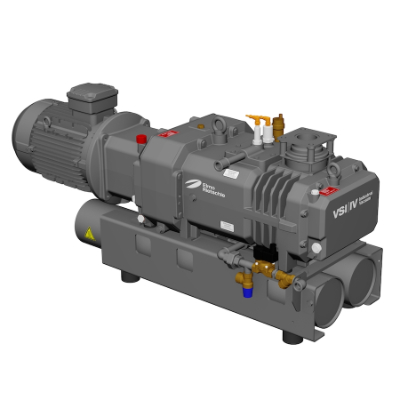

V-VCS Rotary Vane Vacuum Pumps

These oil-lubricated, small & light pumps are noiseless & economical. They offer noise output up to 67 dB(A), making them suitable for busy environments. They eliminate the need for the maintenance and allow less filtration for enhanced oil particulate removal.