These cookies make our website work. They include logging personal details, like login/sign-up or account data, browser information, images & videos, and shopping cart journey.

In addition, we use optimization cookies to test new features and designs on our website. The information collected helps us improve our website and customers' experience.

These cookies are used to understand the performance and relevancy of our adverts, to provide you with personalised adverts on other websites and social media, to track when you have arrived at our site from a recognised third-party affiliate website, and to track if you made a purchase based on the adverts we displayed to you.

These cookies enable us to provide personalised product and content recommendations, to make the browsing experience more relevant to you.

These cookies are used to offer customer surveys and feedback, to improve search results, and to allow you to share content from our website on social media.

These cookies help us improve our website by collecting and reporting information on how you use it.

BEECH DESIGN & MANUFACTURING

Since 1996, Beech Design & Manufacturing, a division of MSI, has been manufacturing material handling equipment for industrial / professional market. This ISO 9001:2015 certified company is headquartered in New Philadelphia, Ohio, USA. Read More

Filter

Material Handling

Material Handling Filter

Jib Crane Components

Flow Control Valve

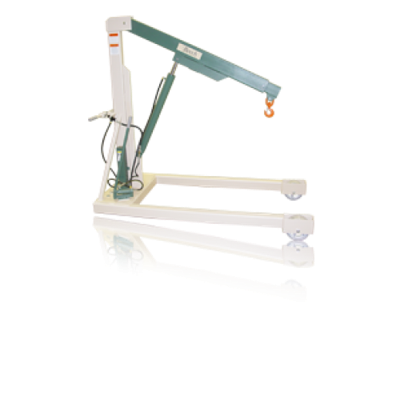

Jib Cranes

Stackers

About Beech Design & Manufacturing

The brand's product line includes stackers, cranes, lift tables, power-driven fork / platform stackers and power-driven counterbalanced cranes. Beech Design & Manufacturing counter balanced fork stackers feature a safety bypass relief valve for preventing components while overloading. They have a counterweight for an even balance of stackers. These stackers have floor locks for locking the stacker on point while loading / unloading. Beech Design & Manufacturing counter weight cranes are designed without front legs, thus eliminating interference with load lifting or equipment. They have phenolic wheels for easy manoeuvrability and feature bypass relief valves for preventing components while overloading.

Things to Consider

Cross-Reference Alternatives

Some Beech Design & Manufacturing MPNs cross individual references to the equivalent Caldwell, Vestil and Wesco model numbers. So, if you're looking for a competitor item that is either out of stock or obsolete, chances are Raptor Supplies has the equivalent Beech Design & Manufacturing products available.

Shipping

These Beech Design & Manufacturing products range from small to large sizes. They may require careful packaging as some items might get damaged while shipping. Hence, these Beech Design & Manufacturing items are delivered by courier shipment and air freight for minimum downtime.

Major Trade Names

Materialift Vertical Reciprocating Conveyors

Beech Design & Manufacturing's Materialift conveyors are designed to lift & transport heavy loads such as steel beams and pipes in factories, warehouses and construction sites. They meet or exceed the...Read more

LOAD REDI Lift Tables

LOAD REDI lift tables are used to lift and position heavy loads such as pallets, containers and equipment, reducing the risk of strain and injury associated with manual handling. They are ideally used...Read more

Frequently Asked Questions

Are Beech Design & Manufacturing lifting devices tested?

Yes, the brand's lifting devices are tested at 150% more load than the rated capacity.

What are the safety feature of LOAD REDI Lift Tables?

Load Redi Lift Tables come with safety features such as safety brakes, emergency stop buttons, and safety guards to prevent accidental injuries. The lifting platforms are also adjustable to fit different load sizes and can be customized to meet specific requirements.

How to maintain Beech Design & Manufacturing lifting devices?

- Perform regular visual inspections to check for any signs of wear and tear.

- Clean the lifting mechanism and components regularly to prevent buildup of debris and contaminants.

- Keep the hydraulic pump and fluid at the correct level and change the fluid.

- Inspect and replace any worn or damaged components as needed.

- Use the lift table within its rated weight capacity to prevent overloading and potential damage.